ATEX is the abbreviation of “Atmosphères Explosibles”. The series of ATEX guidelines and standards are the EEC reference for protection from the risk of explosions in the presence of flammable gas and/or dust. An explosive atmosphere may contain flammable gases, mist, vapours or flammable substances. If the concentration of these substances is sufficiently high, then, in combination with air and an ignition source, an explosion may occur.

HOW DO GAS AND DUST EXPLODE?

The necessary conditions for an explosion or fire are the following:

- The presence of a combustible substance;

- Oxygen;

- An ignition source.

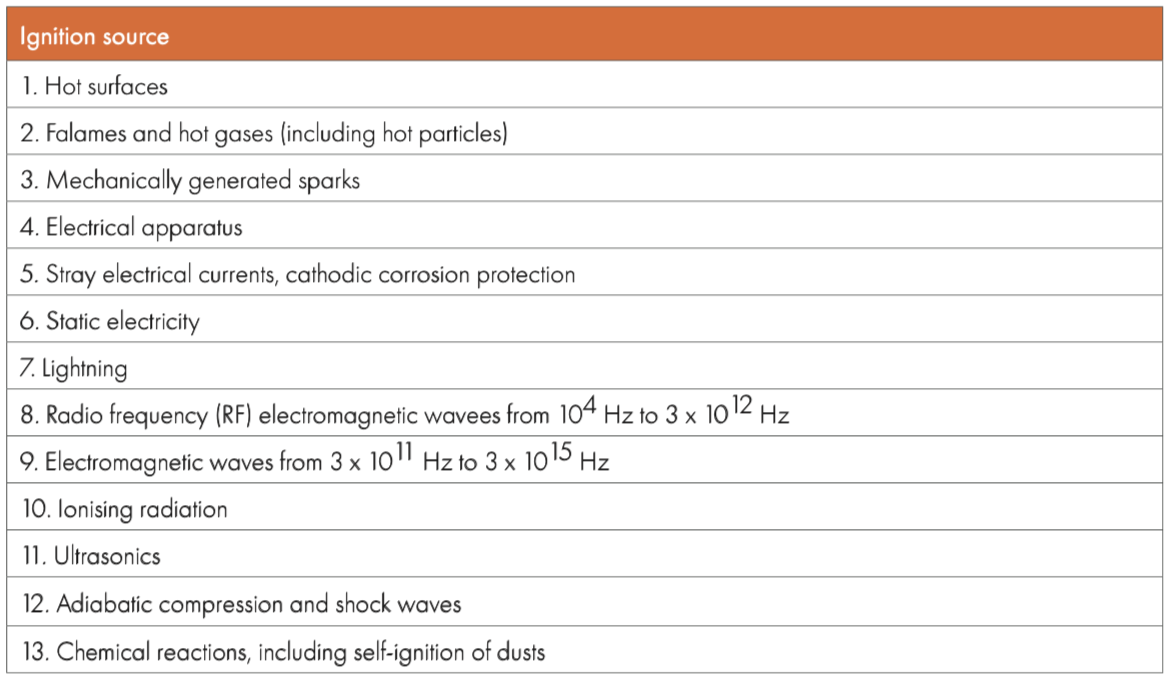

Examples of ignition sources are hot surfaces, open fire, electrical sparks, electrostatic discharges and sparks from abrasive activities, cutting activities, electrical welding and spot welding machines (see also attachment).

Flexible connections and flexible connecting pieces do not require an ATEX certificate: they do not have an energy source and do not transfer energy. The products are usually made of plastic and this group of materials are natural insulators.

Insulators are characterized by high surface resistance (1013 – 1018 Ω).

This means they are poor conductors of electricity. When (static) electricity cannot flow away, electrostatic charge occurs. This accumulation of charge may be a source of ignition. Once there is sufficient charge, discharge will occur through flashover. For this reason, only plastics with a lower surface resistance (≤ 2.5 · 1011 Ω) are used in explosion hazardous environments.

WHAT SUBSTANCES ARE FLAMMABLE?

There are upper and lower limits for the concentration of combustible materials (gas or dust) in the atmosphere that determine the likelihood of an explosion occurring. The size of the particles plays a fundamental role, especially in the case of dust. This is why the substances in the ATEX guidelines are classified according to ignition sensitivity.

GAS AND VAPOUR

Gases and vapours occur in the petrochemical, beverage, herbal industry, petrol stations/fuel distribution areas, paint production, processes where washing operations use cleaning agents, the chemical and metal industries, mining, and bio-energy generation.

Propane, ethylene and oxygen are examples, but gases produced as a result of evaporation of organic liquids such as alcohol, hydrocarbons, acetone, xylene, turpentine, lubricating oil, etc. are flammable. Gases and vapours are classified as follows:

- IIA includes propane, butane, kerosene;

- IIB includes ethylene, hydrogen sulphide, ethyl ether;

- IIC includes hydrogen, acetylene, sulphur carbon.

SOLID DUST

Dust frequently occurs during transport, transshipment and/or transfers. All work environments with combustible powders or where dust is released in enclosed spaces, carry the risk of a dust explosion. Examples of types of companies where dust explosions can occur are:

- grain handling companies;

- dairies;

- sugar factories;

- compound feed companies;

- paper processing companies;

- furniture factories;

- recycling companies;

- plastics processing companies.

Examples of combustible material include: cereal products, flour, starch, sugar, wood dust, animal fat, light metals, coal, plastic and textile. Each combustible material has characteristics that are important in the choice of explosion-proof equipment, such as:

– The applicable substance group (IIIA, IIIB or IIIC):

IIIA = combustible flyers with dust particles > 0.5 mm

IIIC = electrically non-conductive dusts with a diameter < 0.5 mm

IIIC = electrically conductive dusts with a diameter < 0.5 mm

– Ignition temperature (temperature at which a dust cloud is ignited)

– Smoulder temperature or glow temperature (temperature at which a 5 mm thick layer of dust will smoulder). For example: lignite, dust group IIIC, ignition temperature 380ºC, smoulder temperature 225ºC.

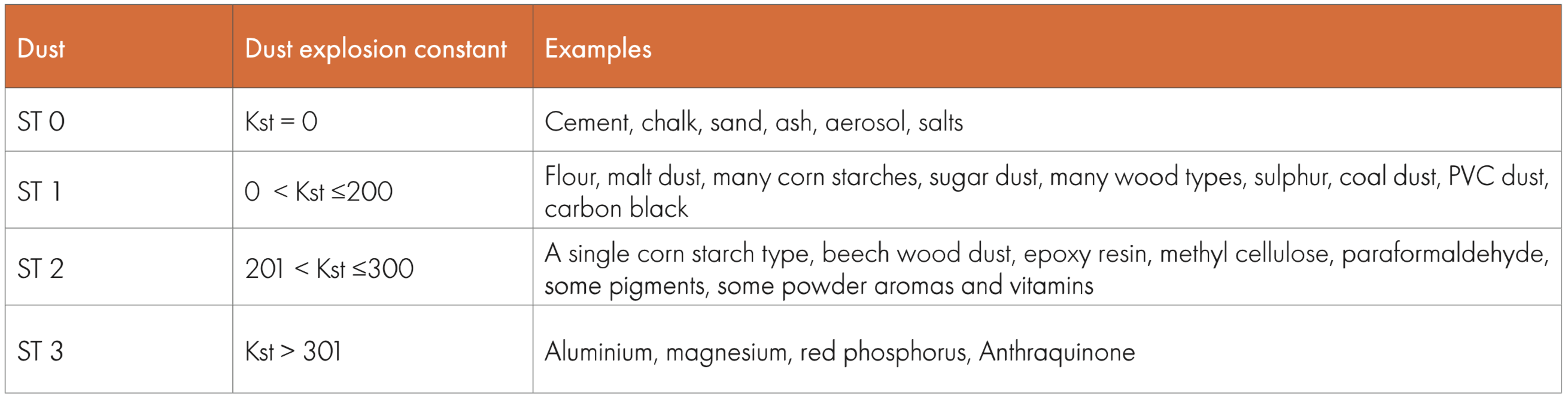

Dust is also classified according to the degree of explosion intensity, the dust explosion constant Kst. This includes speed and volume increase.

An online database is available on the Staubex website, where the combustion and explosion characteristics of a large number of dusts are collected: Staubex databank.

ATEX – LEGISLATION

The ATEX directives impose safety principles that must be observed by manufacturers and users. This concerns the following directives:

1. Directive 99/92 / EC (formerly known as ATEX 118a or 137) regarding the minimum requirements for improving the health and safety of personnel at risk from explosive atmospheres. Mandatory from 1/7/2003. The directive is not aimed at manufacturers or suppliers of equipment, only at employers.

2. Directive 94/9/EC (formerly known as ATEX 100a or 95) on applying the laws of Member States regarding equipment and protective systems intended for use in potentially explosive environments. Mandatory from 1/7/2003. This is primarily intended for manufacturers of equipment who sell the equipment on the market.

The latter was replaced by ATEX Directive 2014/34/EU, as from 20 April 2016.

The ATEX guidelines apply to Europe, however, there are other similar fire and explosion protection regulations, such as IEEx and HazLoc.

HazLoc and the relevant product certification are intended for the US and Canada. IECEx refers to the rest of the world: especially Australia, New Zealand and China.

RISK ZONES

Explosion risk zones are classified according to the frequency and duration of the presence of explosive gas or dust. Dust not only takes into account flowing dust but also dust layers and accumulation of flammable dust, whether or not swirled up into dust clouds. All types are included in this classification. The following hazardous zones are differentiated (gases and solid dust):

The level of the requirements for equipment and machinery therefore depends on the category.

Category 1 is the most stringent class:

Equipment in this category may be used in environments where there is a more or less continuous explosive hazard mixture: zone 0 or 20 (naturally, it may also be used in other zones).

Therefore, ignition sources must be avoided even in extreme error situations. Category 1 equipment must be inspected by specially qualified institutions (so-called Notified Bodies).

Category 2 is for Zone 1 or 21:

Here, the requirements are slightly less stringent. Electrical equipment must still be inspected by a Notified Body. For mechanical equipment, the manufacturer may carry out the inspection, but the relevant file must be submitted to a Notified Body.

Category 3 is the least stringent zone: 2 or 22:

Here, it is sufficient to demonstrate that ignition sources do not occur during normal use. The manufacturer may carry out the inspection without the Notified Body.

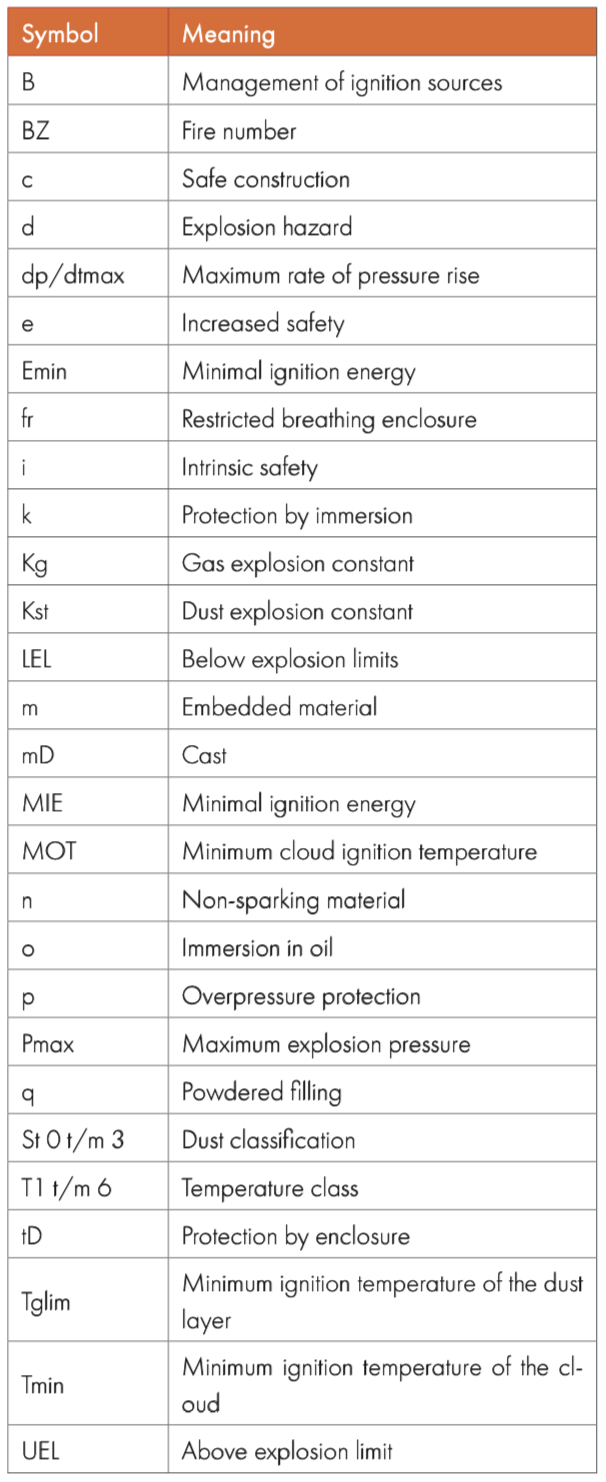

ABBREVIATIONS AND SYMBOLS

ANNEX – DEFINITIONS

– Risk of explosion: may occur in all company workplaces where combustible and explosive substances are used (dust and / or gases).

– Explosion: is a suddenly severe energy eruption associated with the build-up of pressure (wave).

– Ignition sources: hot surfaces, open fire, electrical sparks, electrostatic discharges and sparks from abrasive activities, cutting activities, electrical welding and spot welding machines.

– Dust: dust is a finely distributed solid matter of arbitrary shape, structure and density.

– Dust explosion/gas explosion: a dust explosion/gas explosion is a rapid progressive combustion of a mixture of flammable dust/gas with air. The volume expansion of the gases heated by the combustion results in a noticeable pressure increase.

– Flammable/explosive air mixture: air mixture of a flammable product in a volatile form (gas, vapour, mist, dust, fibres), at a ratio and under conditions that allow ignition to enable the independent combustion of the entire mixture. When the fire propagation in such a mixture is great and occurs with a pressure increase, this is referred to as an explosive atmosphere. When the fire propagation in such a mixture is small and without a pressure increase, this is referred to as a flammable atmosphere.

– Zone classification: Explosive atmosphere, consisting of a mixture of combustible materials in the form of gas, vapour or mist with air (zone 0, 1 or 2). Explosive atmosphere, consisting of a cloud of combustible dust in air, including deposits, layers and mounds of combustible material (zones 20, 21 and 22).

– Explosive atmosphere: a mixture of air and flammable substances in the form of gases, vapours, mist or dust in which, under atmospheric circumstances and after ignition has occurred, combustion spreads to the entire unburned mixture.

POTENTIAL IGNITION SOURCES