Features

- Easy flexible installation

- Compensates for thin flexible sleeve materials

- Leak free flange coupling

- Leak free hoseclamp connection

- Air-tight and powder-tight connection

- Great seal for warped flanges

- Great compensation for Bolt tensioning differences

- Easy ratio – sleeve compression to installation gap

Flange padding seal / Cuff padding seal

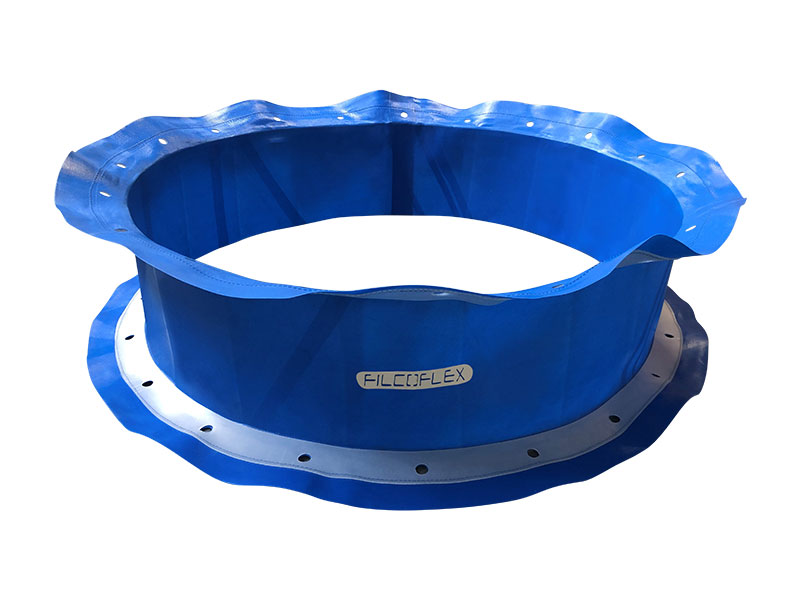

Filcoflex now offers an additional padding seal on flange surfaces and end cuffs of flexible connectors and sleeves to provide a perfect seal combined with easy installation. Available in a number of soft rubber materials, for hoseclamp cuffs and bolt pattern flanges.

What to use it for

A flexible sleeve is often made in thin materials like Poly Urethane, PTFE and coated fabrics. Most these flexible materials have great flexibility and make an excellent sleeve or cuff, but they are thin, and there are not soft and spungy which would be required to form a good seal between flanges or under a hoseclamp. For these applications we offer flange padding or cuff padding.

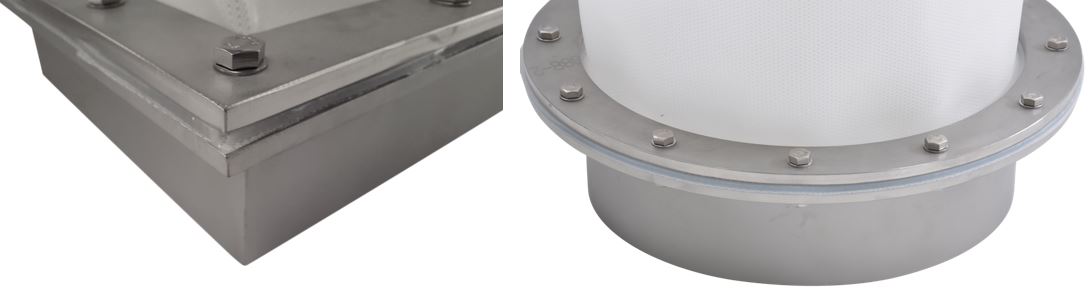

Flange and Cuff padding seal fixing methods

Flange or Cuff paddings are most often a silicone gasket that is fixed to the flange of the flexible sleeve. Other materials are also available as you can find in our “available materials” table.

Most cuff paddings or gaskets are a different material as the flexible sleeve or are not thermoplastics and therefor can not be welded to the flexible sleeve flange or cuff.

By stitching the padding to the cuff or sleeve it makes it easier for operators and mechanics to fix the fix the sleeve to the machinery because it keeps a better shape. Also the padding can not be installed wrong because it is fixed in the right place. Factory employees easily recognize how to place the sleeve, and the right slack / extra compression of the sleeve when fitting it speaks for itself.

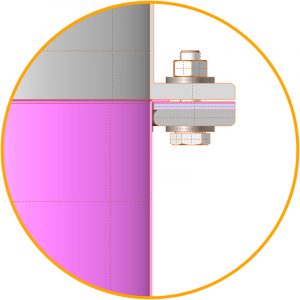

Installing the flexible sleeve

The surface of the padding and that of the flexible need to be able to move over another when clamping down the hoseclamp or bolted flange. That is why Filcoflex stitches the flange or cuff padding to the flexible sleeve along the outer perimeter of the flange or cuff. Once the flanges or hoseclamps are installed or the stitching is beneath the hoseclamp or the stainless steel flange the yarn or the stitching can not collect any dust or dirt, and will not be contaminated. The stitching is only exposed when the clamps or flanges are removed again.

Poly Urethane padding is welded to the original sleeve cuff or flange, and mostly serves the purpose of providing a more robust cuff or flange, not so because of the softness seeing Poly Urethane is quite hard.

Fitting with an Aramid silicone coated explosion cover

Using a Flange padding you also provide a good surface to clamp in another explosion cover sleeve such as the Filcoflex AWSR2ri aramid with silicone coating explosion pressure covers. The padding allows for the stitched seams of the aramid cover to be airtight using the softness of the flexible sleeve flange padding.

Hoseclamp assembly

Hoseclamps can be air and dust tight using a cuff padding. Cuff paddings for hoseclamp fittings are always positioned around the outside. This lets the hoseclamp clamp down in the softness of the padding and provide an air-, powder- and fluid-tight seal.

Large diameter flanges are easier to fit and made leak free using flange padding.

Hygiene

Hygiene is important for many Filcoflex customers, the flange padding is attached on the outside of the flange, where the counter flanges compresses the flexible against the machine flange. This prevents having an extra transition on the inside, or any possible extra crevice or edge. Filcoflex offers this as their standard side where they attach the flange padding.

The standard also works for industrial applications. But if the padding is required to be between the flexible and the machine flange, we can also offer this without any extra charge.

Once a flexible sleeve is connected, there may be some compressed padding be sticking out of the clamp or flange. This can easily be cut away with a knife. But can also be left in place.

Available Padding Seal materials

Filcoflex offers a number of flange padding materials, some are available in various thicknesses.

| Silicone | Translucent | Food contact compliant | 2mm / 3mm* |

| EPDM | Black Antistatic | Food contact compliant | 2mm / 3mm |

| Poly Urehane | Transparent | Food contact compliant | 1mm / 1.5mm |

Other materials available on request

* silicone 2 and 3mm are the standard flange padding seal and cuff padding seal