Advantages

- Metal Detectable

- Color Detectable

- Excellent flexibility

- Smooth welded seams

- Great aging resistance

- Non porous

- Smooth surface

- No material degradation

- Abrasion resistent

PUMAG08

A special Polyester Urethane compound sheet material in a solid blue color designed to be metal detectable, and color detectable.

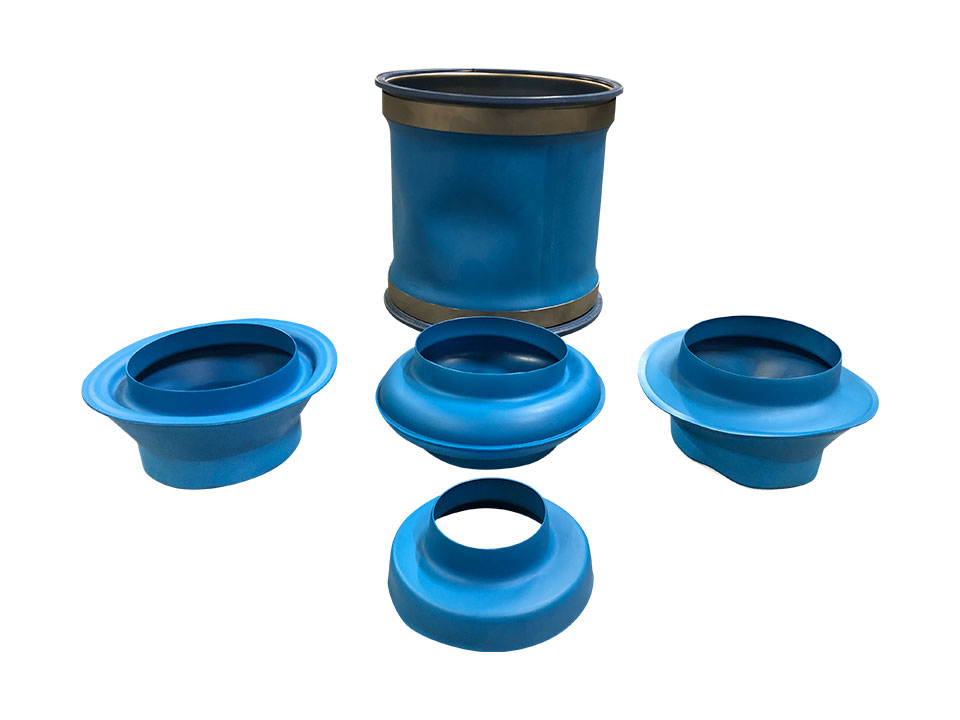

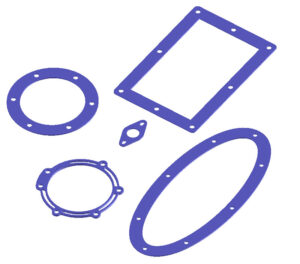

Fine metallic powder is added in the compound to make it metal detectable and X-Ray detectable. Filcoflex now offers metal detectable flexible connections, metal detectable flexible sleeves, metal detectable bellows. Metal detectable gaskets can also be cut from this metal detectable sheet material.

Metal detectable products are commonly used in food production environments, where consumables such as modular belting, cable ties and pens have the potential to contaminate the supply chain. If any part of a metal detectable product becomes detached, it will be picked up by an industrial metal detector on the production line, preventing supply chain breakdown and expensive recalls. Metal detectable fillers are converted into an ultra-fine powder and extruded into the Poly Urethane Masterbatch.

The minimal detectable size of material particles must be verified in real using conditions. Metal Detectable sheet samples can be supplied for your in-house testing with your detection devices. The solid blue color metal detectable poly urethane sleeves and bellows can also be used for black-out sleeves covering, transparent flexible connections used in light and spark detection explosion prevention systems.

Applications

Metal Detection, X-ray Detection, Color Detection. Stationary, Vibratory, Gyratory, Sifters, Screeners, Feeders, Fluid Bed, Static Cool Bed, Bin dischargers, Hoppers, Conveyors, Packaging equipment, Storage silos, Screw conveyors, Valves, butterfly valves, Rotary valves, Tanks, Silo’s, any sort of product handling equipment, Air ducting, Fans, Inflatable seals, Light Barrier, Bellows, Load cell (high volume, weight, and capacity), Harmonica’s, Telescopic applications, Vacuum formed shapes.

General properties

| Name | PUMAG08 |

|---|---|

| Description | Poly Ester Urethane Magnetic Detectable Blue |

| Color | Solid Blue |

| Surface | Gloss 1 side / Matt 1 side |

| Surface Roughness | – |

| Wall Thickness | 0,80mm / 0.0315 Inch (+/-10%) |

| Hardness | – |

| Tensile Strength | 35 MPa |

| Maximum Elongation | 1000% |

| Operating Temperature | -20 °C to 80°C -4 °F to +176 °F |

| Max. Surge Temp | +90 °C / +194 °F |

| Low Temperature Flexibility | Good |

| Air Permeability | 0 |

| Type of Material | Sheet on roll, 1000x20000mm |

Pressure Resistance for Flexible Connectors

0,3 Bar / 4.4 PSI For temperatures up to 80 °C / 176°F. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

Weighing Applications

High volume weight and capacity weighing and dosing applications please see “weighing and dosing guide” for further information.

Chemical Resistance

- CIP resistant (see CIP chemicals guide)

- Cleaning Chemicals (see cleaning guide)

- For a detailed chemical resistance please see our chemical compatibility chart

ATEX & Explosion Safety

PUMAG08 is not antistatic or static dissipative. There are no specific explosion safety tests performed.

Food Contact Compliancy

European Union (EU) Food Contact

According to the available information from the suppliers, the raw materials used to produce the TPU film PUMAG08 blue color are composed of ingredients which meet the current requirements of the Commission Regulation No. 10/2011. All the monomers and additives are listed. Some substance have specific migration limits (SMLs) and other restrictions. Possibly, the Declaration of Food Compliance (provided for M.O.C.A. by Regulation (EC) No. 1935/2004) will be issued only after an appropriate evaluation of the specific purposes of the end-products by the customer.

According to the management system of the food safety adopted by Filcoflex B.V., the analytical test, connected to the Declaration of Food Compliance, will be carried out subsequently the planning and the fulfillment of the product. Specific sales agreement between Filcoflex B.V. and customer must be previously defined.

US Food and Drug Administration (FDA)

According to the available information from the suppliers, the raw materials used to produce the TPU film PU MAG 08 BLUE color are composed of ingredients in compliance with 21 CFR US FDA : 177.2600. Possibly, the Declaration of Food Compliance will be issued only after an appropriate evaluation of the specific purposes of the end-products by the customer.

According to the management system of the food safety adopted by Filcoflex B.V., the analytical test, connected to the Declaration of Food Compliance, will be carried out subsequently the planning and the fulfillment of the product. Specific sales agreement between Filcoflex B.V. and customer must be previously defined.

Testing reports, Migration Testing, Laboratory research

Specific migration testing can be performed upon request for European, US or Chinese food contact compliances.

Production Methods used

Joining / Bonding:

- Welding

- HF high frequency welding

- Welding the material and cooling it down under compression with Radio Frequency to make the TPU material flow nearly seamless to form a uniform thickness with the original material wall thickness.

- Heat contact – with silver alloy heating element

- Welds are welded surface to surface after which the weld are compressed while cooling.

- Hot air – hot filtered and conditioned contaminent-, oil- and grease- free compressed air

Cutting:

- Stainless Steel knives

- Water Jet cutting