Features

- High Grade Polyester Needle Felt

- With or Without PTFE Membrane

- Antistatic and Non antistatic version

- All types of end connections available

- Available in standardized sizes

- Tailor made / Custom made.

- Breather bags designed for breathing /

- Pressure leveling of vessels and hoppers.

- Might be required using 100% sealing.

- Couplings and fittings on process

- Components and flexible connections (sleeves).

Breather Bags

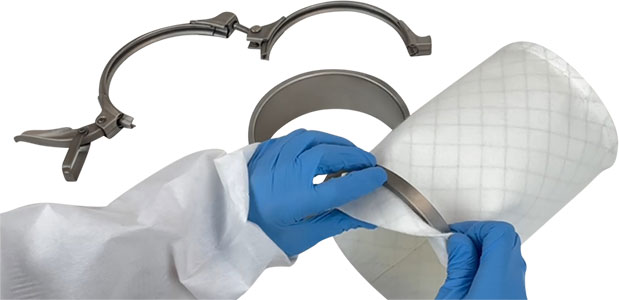

Breather bags designed for the venting of equipment such as hoppers and contained vessels. When your equipment is sealed 100% by using Filcoflex flexible sleeves and flexible connectors venting is required in some situation to prevent over pressure or negative pressure in your contained process equipment

Permeable / Breathing 100% polyester needle felt in antistatic food grade polyester needle felt for explosion hazardous environments. PNV 7506 AS FG. Food contact compliant according to FDA and (EC) 1935/2004 and (EC)10/2011. Explosion safe for ATEX environments. Tested and validated by independent laboratories.

Breather bags are also available in other materials, polyester needle felt with or without membranes, non-anti-static, and non-food versions, as well as our 100% PTFE breathable fabric “PTFE 310”.

Breather bags have a standardized length of 300mm, for both the conical top with eyelet as well as the round flat bottom. Any custom length can be provided from 100 to 2000mm in increments of 5mm without any extra charge.

Every breather bag can be made with support rings or reinforcement rings for negative pressure or over pressure. The use of a filter cage is also recommended in negative pressure applications to prevent collapse of the breather bag.

Top closed

The definition of a breather bag or filter bag is that 1 side is closed. Filcoflex offers 2 distinct variations of closed ends.

Flat top round bottom with a handle

The handle is stitched on the same seam as the bottom, to prevent any additional puncture of the bottom. The flat top allows for the use of an inside filter cage to prevent the collapse of the breather bag.

Length: starting from 300mm (standard) up to 1000mm in 50mm increments.

Conical Top with stainless steel eyelet

If hygiene is a top priority the conical top prevents powder or dirt staying behind on the top of the closed end. An outside support pilar can be used to hang the stainless-steel eyelet. Special conical inside cages can be manufactured upon request.

Length: starting from 150mm up to 1000mm in 50mm increments. 250mm is the standard length.

General Properties

| Product Name | PNV 7506 AS FG |

| Description | Polyester Needle Felt with Stainless Steel matrix One side with PTFE filter Membrane Anti-Static Food Grade |

| Color | White with stainless steel matrix |

| Wall thickness | 2.10 mm / 0.08267 Inch |

| Weight | 500 grams /M2 |

| Chemical treatment | none |

| Special treatment | Anti-static due to woven in stainless steel mesh matrix. |

| Conductivity | < 103 Ohm |

| Explosion Safety | Suitable for explosion hazardous environments |

| Operating Temperature | 150 °C / 302 °F dry |

| Max. Surge Temp | 170 °C / 338 °F dry, maximum 6 Hours |

| Air Permeability | 30 – 70 liter/dm2/min, at 20mm Water column (DIN53887) |

| Filtration Class | < 0,10 % 0,06 M/sec class M Bia Norm |

| Food Contact Compliancy | FDA21CFR 177.1590 + FDA21CFR 175.300 + FDA21CFR 177.1550 (EC) 1935/2004 + (EC)10/2011 + (EC)2023/2006 and more Migration tested with Simulant B, D2 and E for 10 days |

Material datasheets

For the full material datasheet, explosion safety and food contact information, please see the Material datasheet for our air permeable fabrics:

PNV 7506 AS FG

Explosion safety information is described in detail, including testing reports from independent laboratories, Migration testing reports, electrostatic conductivity testing reports.

Alternative materials

Other permeable fabrics available upon request such as:

- Woven 100% PTFE fabric – PTFE 310.

- 100% polyester needle felt in multiple qualities.

Connections / Couplings available on breather bags

Filcoflex offers a wide range of end connections on the breather bags, same as we do on the flexible sleeves. The most common couplings and fittings are:

FSC

Stitched in Jacob coupling flanges (no additional gasket required). No tools required.

Ø: 60/80/100/120/140/150/175/200/224/250/280/300/315/350/400/450/500/560/600/630

FDM

Pressed on Jacob coupling flanges (replaceable gasket). No tools required.

Ø: 60/80/100/120/140/150/175/200/224/250/280/300/315/350/400/450/500/560/600/630

O – unworked end – disposable solution

Unworked end, suitable to be fitted with:

Jacob style coupling

Just like our FSC, the breather bag folds around a Jacob flange and connects using a quick connect clamp. Disposable, hygienic and the Cheapest breather bag with a modular quick action coupling.

Ø: 60/80/100/120/140/150/175/200/224/250/280/300/315/350/400/450/500/560/600/630

Hose Clamp

(9/20/25mm) or other types of clamps. Fitted by placing it on a tube and fixing it with a hose clamp of any width.

Ø: any diameter; round or rectangular

SIF

Snap-In Fitting B shaped cuff stitched in for a clamp free connection. No tools required.

Ø: 100/125/150/200/250/300/350/400/450/500/550/600 etc.

LFR

Pressed on Tri-clamp coupling flanges.

Ø: 60 – 315

ASME BPE / DIN 32676 / ISO1127 / BS4825 pt3 and others

KLB09

Stitched in 9mm worm gear hose clamp.

Ø: any diameter