Features

- Easy Connection

- Explosion resistance 1.5 Bar

- No Gasket, less transitions

- Jacob Coupling in 20 diameters

- Large variety of flexible materials

- Custom made

- Weighing configurations

- Modular system (see accessories)

- Vacuum Resistant

- Breathable materials optional

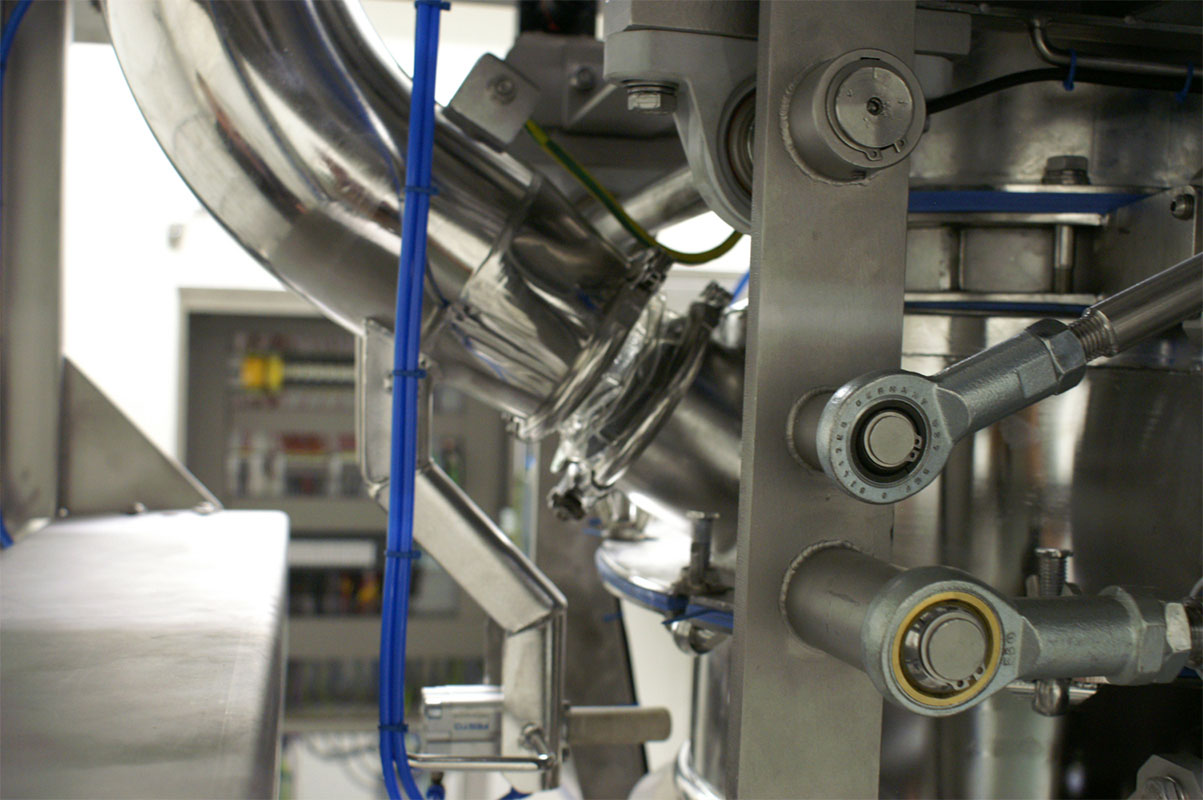

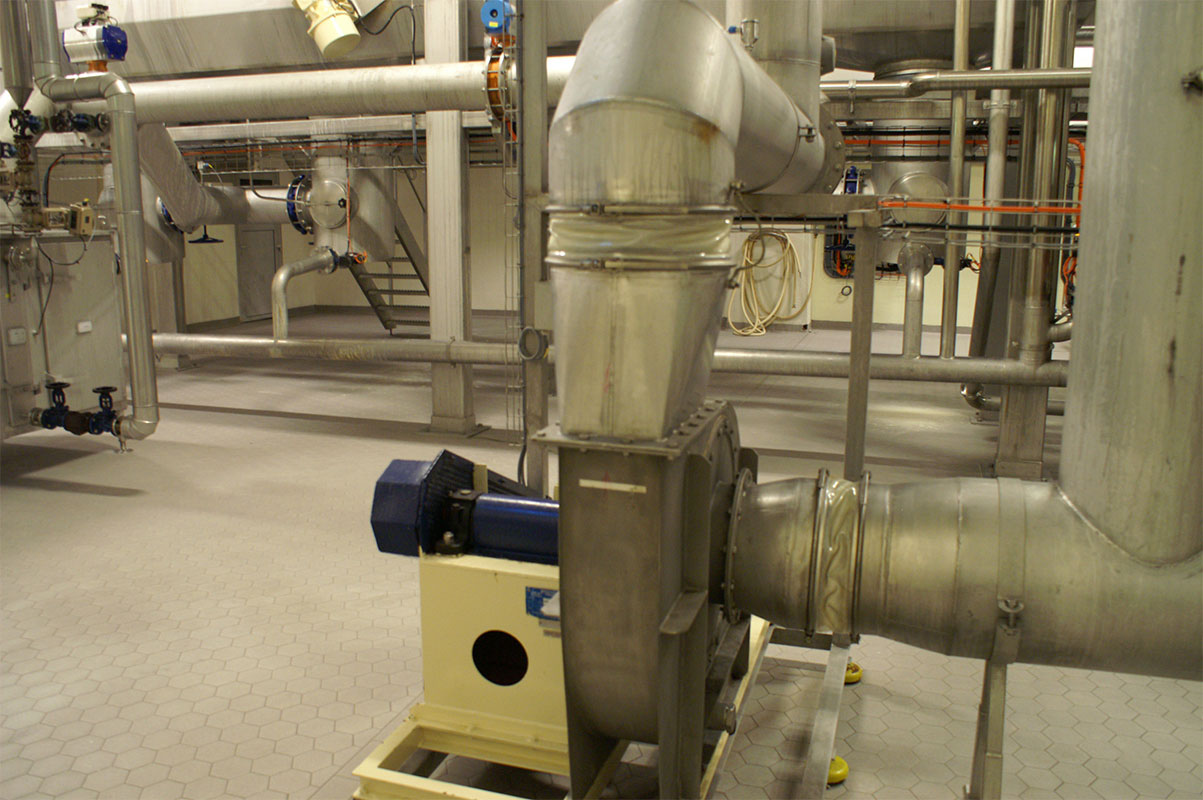

FSC is a flexible connection equipped with a seamed in Jacob coupling.

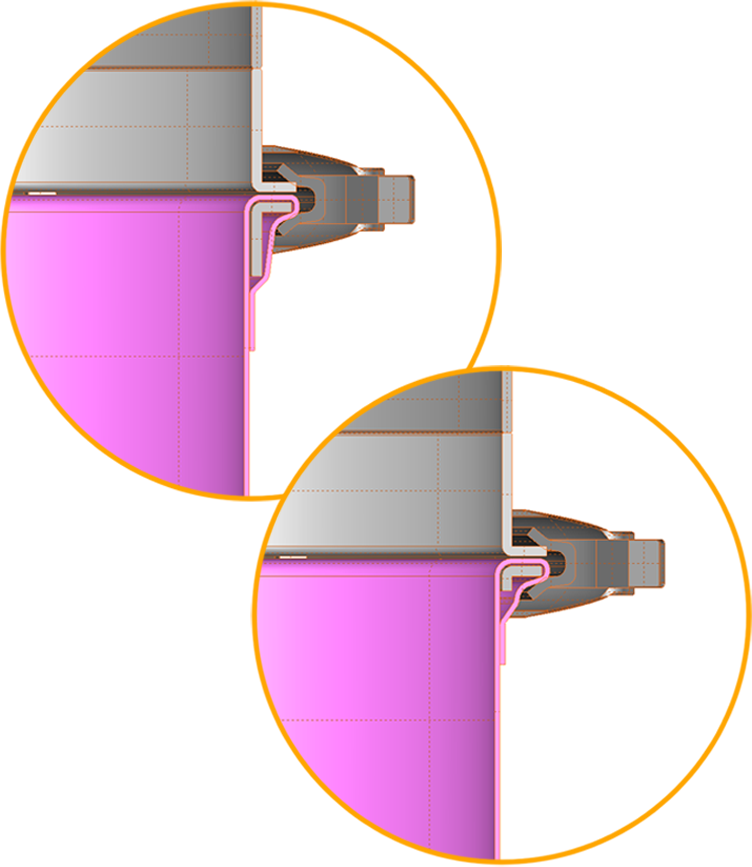

The Jacob coupling is assembled without the use of any gasket and a Quick Connect Clamp for quick assembly. It can also be used with a Bolt Connect clamp for employee safety in case of dangerous applications. For example, when the Flexible connections is close to a rotary valve, screw conveyor, butterfly valve, mill or other mechanical equipment.

The FSC flexible soft connection is a great addition to the already vast program of the modular Jacob tubing system. Because there is no need for any Gasket ring on the flange, there are less transitions or seams where the FSC Flexible connection connects to the ducting or machine flange. This makes it a more simple and smooth design.

The Jacob flanges are seamed in. This can be a seaming technique such as welding if it concerns thermoplastic materials such as Poly Urethane or PVC. Also a stitching technique is available when the sleeve is made from cloth or textile materials and breathable soft connections.

There are many application options, including specific options for weighing and dosing techniques for Atex, foodstuffs and chemical applications.

Magnets, sensors and switches

Also the flanges welded on to the flexible allow to weld brackets to mount electromagnets, sensors or proximity switches. This for the safety purpose to detect if there is a flexible mounted. Also when the clamp is disassembled, electromagnets can keep the flexible in place to prevent leaks or to guard operators from mechanical moving parts that are dangerous. Machines can be switched of when the right electronic precautions are made. Ground studs / earth studs can be added to the metal press rings on each end.

Flange materials

On the FSC the following flange materials are available:

- AISI 304 / DIN 1.4301, 2.0mm, Glass Bead Blasted, (standard)

- AISI 304 / DIN 1.4301, 2.0mm, Pickled and passivated

- AISI 316Ti / DIN 1.4571, 2.0mm, Pickled and passivated

- Others on request

Surface Finish Flanges

Surface Finishes Of the flanges are as described above. Please keep in mind that the flanges are inside the poly urethane sleeve and therefor are not in contact with the product flowing through, including the Cleaning fluids. If you do want your own custom surface treatment we can make that to your specification, such as:

- Pickled and Passivated

- Polished, Ra0.4 or Ra 0.8

- Finish 2B

- H2O blasting / Sublimotion / Viwateq

- Glass Bead Blasted

Variations

- Conical

- Eccentric

- Unparallel flange surfaces

- With inner sleeve

- Y piece / side branches / T piece

- Bellow shape, symmetric and conical asymmetric

- Reinforcement rings against vacuum and over pressure (also in grounded editions)

- End cap or blind cover

- Spiral shaped reinforcement

- Many more

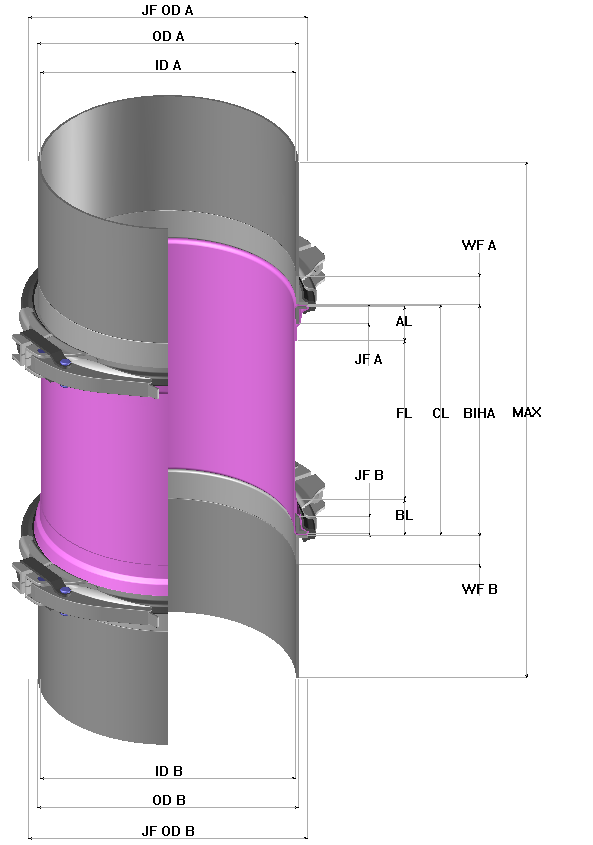

Dimensions

- Jacob is interchangeable with, KMH, NORO, S&W

- Diameters: see table below

- Length is minimum 40mm, there is no maximum length.

- Flange Length;

-

- 5mm – 20mm seamed end (option)

- 15mm – 30mm seamed end (standard)

-

Materials

For more information please go to our Materials Comparison Table.

- Poly Urethane (0.3mm / 1.0mm / 1.5mm)

- PKPU Poly Urethane with knitted polyester ply (0mm)

- PVC, Mipolan (0mm / 3.0mm)

- Poly Urethane weighing bellows

- Step Bellows

- Breathable PTFE woven fabric

- Nomex silicone coated

| Parameter | Explanation |

| JF OD A | Jacob Flange Outside |

| OD A | Tube Outside Diameters |

| ID A | Inside Diameter |

| WF A | Welding Flange Length |

| AL | Seamed in Flange Length |

| JF A | Length Flange |

| FL | Length Flexible Sleeve |

| CL | Length Flexible Connector |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| JF B | Length Flange |

| BL | Seamed in Flange Length |

| WF B | Welding Flange Length |

| ID B | Inside Diameter |

| OD B | Tube Outside Diameter |

| TC OD B | Triclamp Flange Outside |

| Diameters (mm) |

| 60 | 150 | 280 | 450 |

| 80 | 175 | 300 | 500* |

| 100 | 200 | 315 | 560* |

| 120 | 224 | 350 | 600* |

| 140 | 250 | 400 | 630* |

* Only as Bolt Connect Clamp

Ancillerary components

Compatible accessories and components for the FSC and FDM flexible connections with a Jacob coupling / connection.