Features

- Easy Connection

- Hygienic Connections

- No hollow bodies

- Any standardized or custom diameter

- Robust

- Air Tight

- Leak proof

- Large variety of flexible materials

- Standard AISI 316L / DIN 1.4404

- Custom made

- Replaceable gasket (see accessories)

- Reusable metal parts and flanges

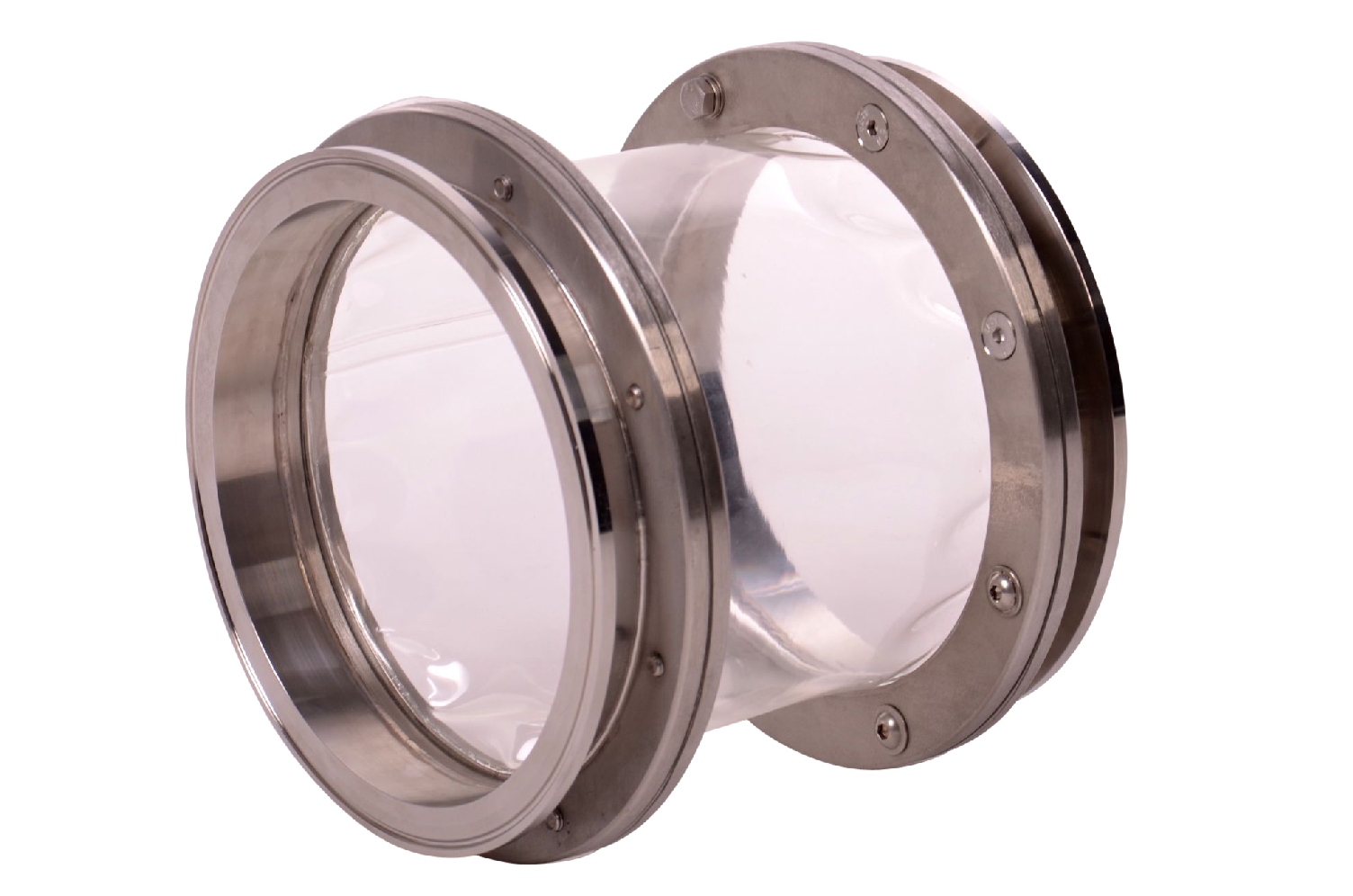

- Suitable for PTFE flexible connections

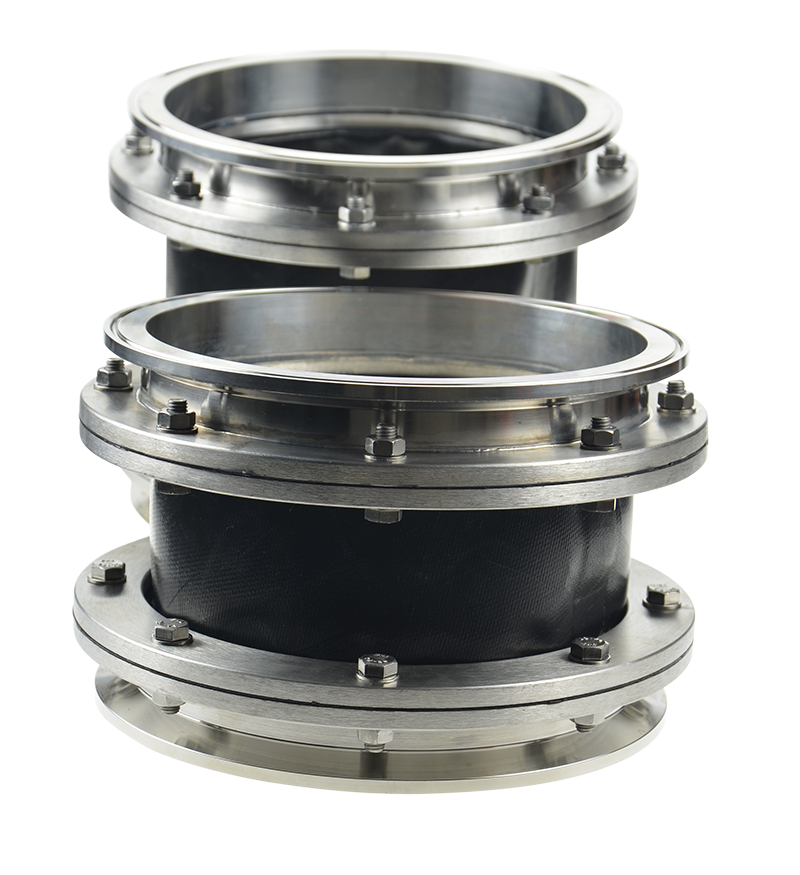

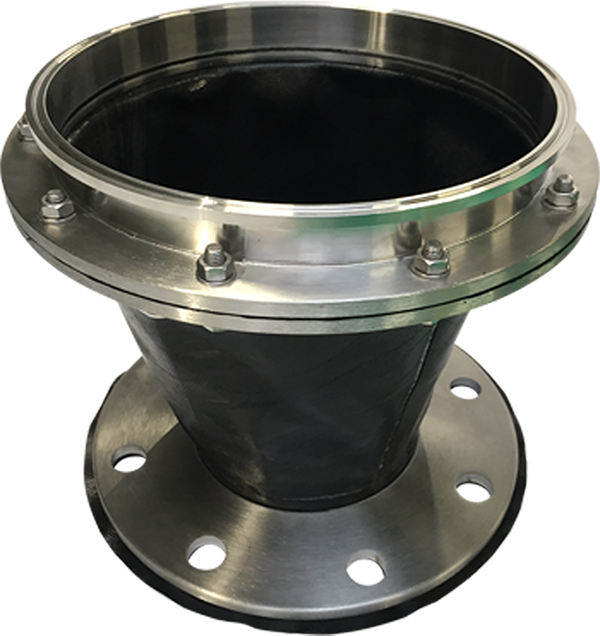

LFDDC is a flexible connection equiped with bolted on Tri-Clamp flanges

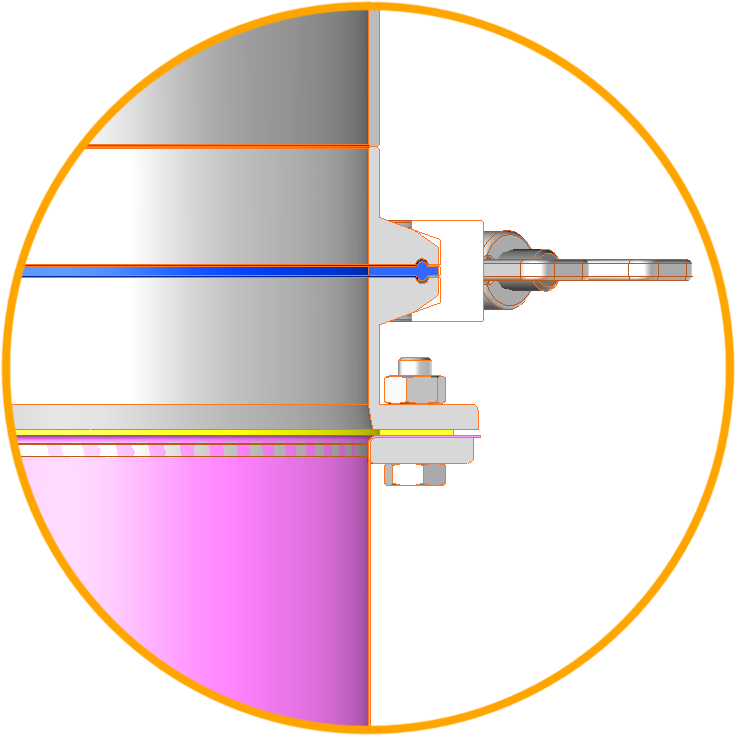

The triclamp flange is machined together with a bolt pattern flanges or is welded together from a bolt pattern flange, together with a tri-clamp flange. The standard tri-clamp gasket is replaceable, as well are the gaskets that seal the adapter flange to the flexible connector. For both gaskets there is a choice out of a wide range of gasket materials. All the metal parts can be re-used when the flexible sleeve is replaced. This is a great advantage.

The assembly can be done by a wide range of bolts and bolt heads, from various materials, washers can be used, as well as nuts, or threaded flanges. Standard is a hexagon head, 2 washers and a nut, for easy disassembly. Other options could be counter sunk bolts, threaded flanges instead of nuts or flanged bolts to replace washers.

By using the standard couplings on the market, you can use a wide variety of connection clamps, such as the standard tri-clamp accessories or the versions which allow for tool release or a padlock for instance.

Brackets or braces can be placed or can be incorporated in the design to fit magnets, switches, contacts or other electronic devices that either detect the presence of a flexible connection or keep it in place such as electromagnets can do, even when the clamps are removed. It can also be made suitable for lock out tag out (LOTO). This can all be of importance when the Flexible Connection is close to a rotary valve, screw conveyor, butterfly valve, mill, other mechanical equipment or when a harmful gas is present inside the tubing.

The LFDDC was initially designed to connect PTFE flexible connections in the most airtight, dust tight, fluid tight manor, and making all the parts re-useable when the flexible sleeve was broken. The design is based on the Flange Fitted principal and has quick connection type flanges welded or machined together with the flange with bolt pattern. Therefor not only tri-clamp is possible, but almost any type of flange with a quick action coupling.

A Flange fitted flexible connection has the best sealing properties and the least amount of crevices or trapped corners or edges, making it the best way to connect a flexible sleeve to a ducting part. By machining a conical edge on the inside, the whole LFDDC becomes free of any unhygienic entrapment or hard to clean places. This makes it a hygienic coupling, because of the rigid metal adapter parts making it vacuum and over pressure resistant at the same time. As well as fully customizable to your demands.

There are many application options, including specific options for weighing and dosing techniques, Atex, foodstuffs, chemical and color and metal detection.

Adapter Flange materials

On the LFDDC the following flange materials are available:

- AISI 316 L / DIN 1.4404

- AISI 304 / DIN 1.4301

- Hastelloy

- PTFE

- Duplex

- Aluminium

- Uranus

- Others on request

Surface Finish Flanges

Surface finishes can be customized, such as:

- Polished, Ra0.4 or Ra 0.8

- H2O blasting / Sublimotion / Viwateq

- Glass Bead Blasted

- Others on request

Adapter Flange Length

- 34mm

- Shorter is not possible

- Longer lengths on request

Variations

- Conical

- Eccentric

- Unparallel flange surfaces

- Added insided Sleeve

- Y piece / side branche / T piece

- Bellow shape, symmetric and conical asymmetric

- Reinforcement rings against vacuum and over pressure (also in grounded editions)

- End cap or blind cover

- Spiral shaped reinforcement

- Many more

Dimensions

- Ø40 – Ø315

- Any standardized diameter possible or see below most sold diameters

- Many Tri-clamp Standards:

- DIN 32676

- ISO 1127

- BS4825pt3

- ASME BPE 2004

- Others

- Available with other types of none tri-clamp connections:

- DIN 11864

- DIN 11851

- And many others

- Length is minimum 100mm, there is no maximum length

Materials

For more information please go to our Materials Comparison Table.

- Poly Urethane (0.3mm / 1.0mm / 1.5mm)

- PKPU Poly Urethane with knitted polyester ply (0mm)

- Silicones (0mm / 3.0mm)

- PKSR Polyester Knitted Fabric with Silicone (0mm)

- EPDM, Gum, Nitrile (0mm / 3.0mm)

- PVC, Mipolan (0mm / 3.0mm)

- PTFE film in various thicknesses

- Nomex

- Woven Fabric (PTFE / Cotton and other)

- Poly Urethane weighing bellows

- Step Bellows

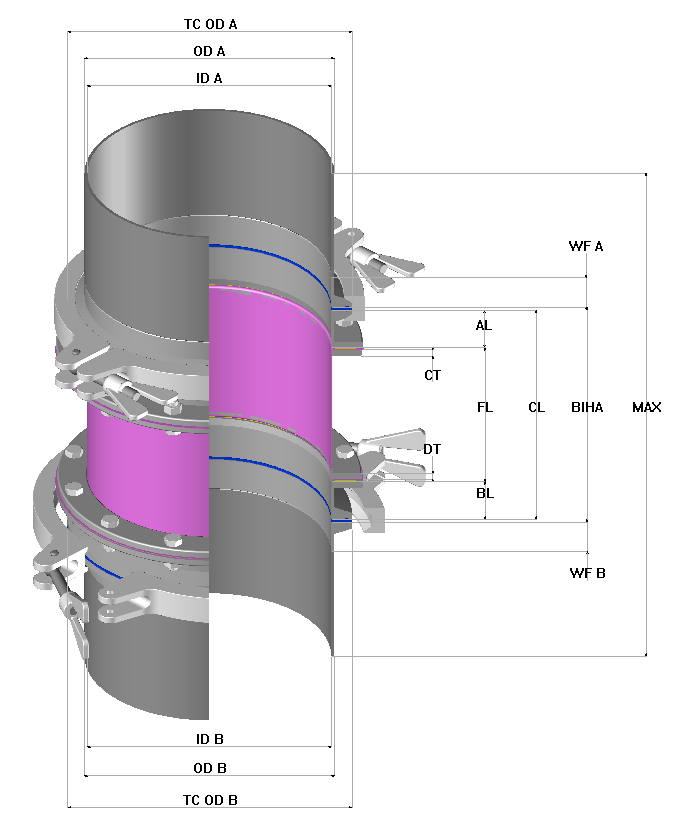

| Parameter | Explanation |

| TC OD A | Triclamp Flange Outside |

| OD A | Tube Outside Diameters |

| ID A | Inside Diameter |

| WF A | Welding Flange Length |

| AL | AdapterFlange Length |

| CT | Counter Flange Thickness |

| FL | Length Flexible Sleeve |

| CL | Length Flexible Connector |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| DT | Counter Flange Thickness |

| BL | Adapter Flange Length |

| WF B | Welding Flange Length |

| ID B | Inside Diameter |

| OD B | Tube Outside Diameter |

| TC OD B | Triclamp Flange Outside |