Features

- Prevent Spray Out

- Covering leaking joints, seals, gaskets, valves

- Visually inspectable

- Color change recognition

- High chemical resistance

- Bright color

- Every size available

- Employee safety

- Environmental safety

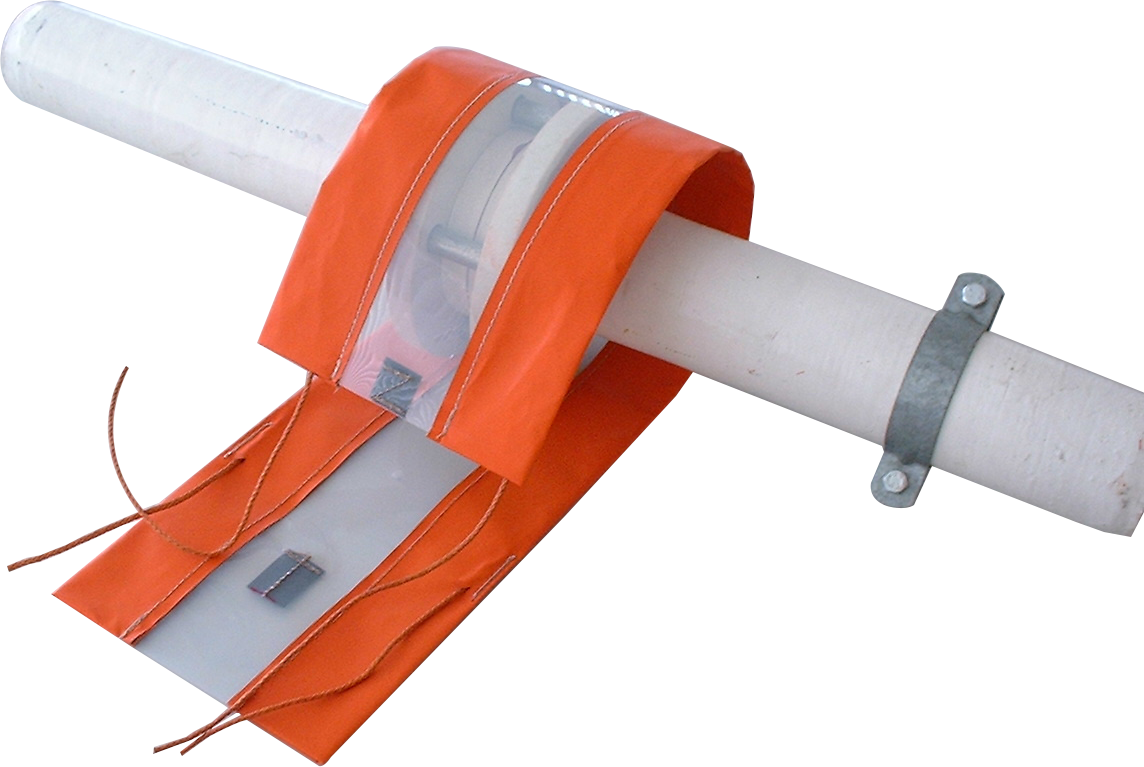

Spray shields

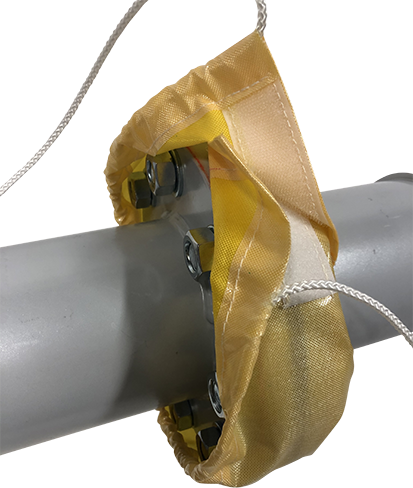

Spray Shields are applicable where liquids are transported through pipes. When pipes, pipelines and valves are used to transport gases and liquids, gaskets are used to seal flange connections. Spray shields are covers that are applied around the flanges of pipelines to protect the environment, employees and the installation as well as for faster detection of leaks using a so-called indicative material to make these flange covers.

Spray shields can be the solution to improve health & safety in industries where chemical solvents are being processed and where extreme temperatures occur in the installation. They are used in chemical plants, oil refineries, paper mills, food processing plants, steel mills, pharmaceutical plants and power generating plants worldwide.

There are a number of variations possible for spray shields:

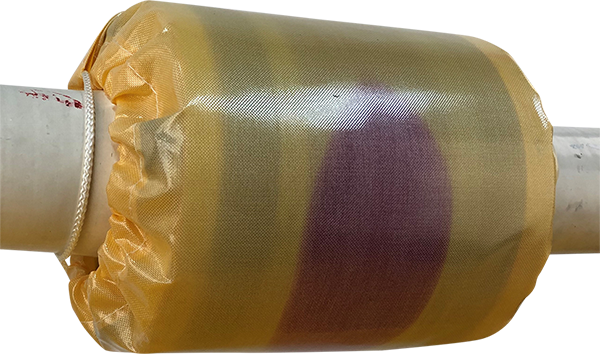

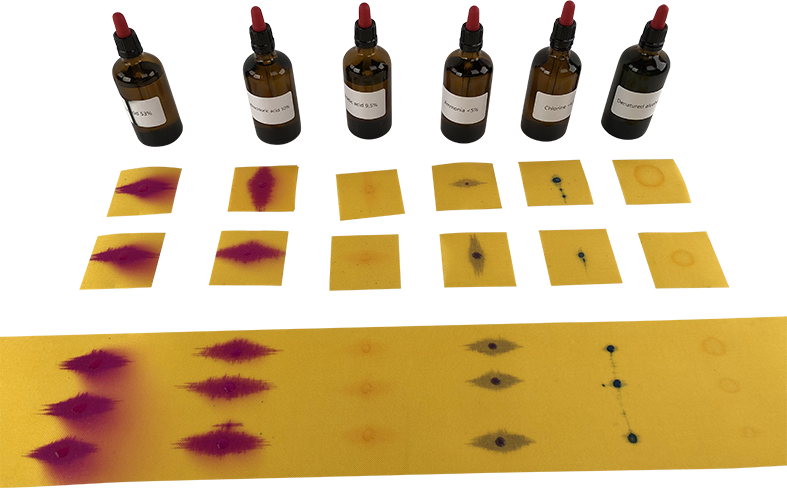

- Chemically resistant and indicative

This Sprayshield is made in a Plain Yellow color which changes to purple when in contact with chemicals. The entire Sprayshield is a color indicator which ensures that the leak always hits the color indicative material (this is not the case when only a PH strip is used at 1 point). - High and low temperature resistant

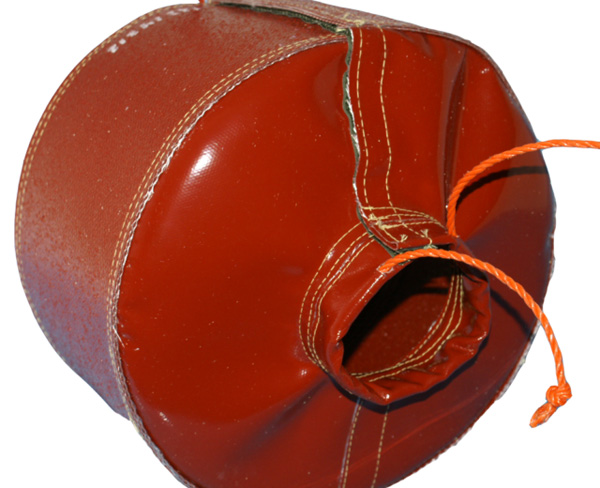

Sprayshield can be made in glass fabrics with silicone coating for a high temperature reistance - High chemical and temperature resistance

Sprayshields made in 100% PTFE films, in translucent or other colors have the highest chemical reistance and temperature resistance.

Chemically resistant & indicative

By using a material that reacts with chemical solvents, these indicative spray shields act as indicators of leakage occurring in flange connections. This way even the smallest leakage can be detected at an early stage, preventing damage to persons and equipment.

The discoloration is visible from the outside, allowing detection without the need for the shields to be opened. As an added benefit the spray shields also prevent a spray out of any leak to its surroundings. The indicative material has a very high chemical resistance and is available in an orange colour that becomes translucent or white when coming into contact with all sorts of chemicals, acids and alkaline solutions.

High & low temperature

In addition to the indicative flange protector for liquids, there are also extremes of high and low temperatures. These designs are not indicative. These heat- or cold-resistant spray shields prevent damage to your installations or equipment. Also, these covers help protect personnel and the environment from the disastrous consequences that can cause a leak.

Special Design

It is also possible to produce spray shields with special features based on the data provided by the customer.

Specific features could be materials that can withstand specific chemicals, certain temperatures or special

conditions. This also allows for varying sizes and shapes with short delivery times.

Filcoflex spray shields are not only made according to DIN and ASA standards, but also according to your specifications so that all your pipes can be provided with the necessary protection. The assembly takes place by tightening and clamping a corded cord, which is also resistant to higher temperatures in addition to chemicals.

Materials

Spray shields can be made in various materials. Indicative Orange Fabric has its own chart that shows you the change of color per chemical and concentration. This is available upon request. For more information please go to our Materials Comparison Table.