Features

- Seamless Rubber

- Smooth Inside

- Standardized diameters

- No Glue, no adhesive

- Gum rubber / EPDM / Nitrile

- Cut to length

- 2 standard long lengths

- Cut to length

- Various thicknesses

Seamless Rubber Hose

Seamless hoses in rubber have a smooth interior surface and a wrapped and light textured outside finish. Seamless hose is made by wrapping a strip of uncured rubber around a mandrel to form a rubber hose. Before the seamless hose is cured inside an autoclave, the rubber hose is wrapped with a textile band to wrap the rubber tightly around the mandrel. When the seamless rubber hose is cured it forms a smooth inside and wrapped outside surface.

Applications

| Flexible sleeves | Rubber sleeves | Bulk Bag filling bladders |

| Connecting sleeves | Gum rubber sleeves | Load out sleeves |

| Chutes | EPDM rubber sleeves | Vibration Isolation |

| Pinch valves | Hoseclamp padding gaskets |

Where to use

The seamless industrial hose is perfect to apply in any sort of industry. Due to the inside smooth surface it can be well used in food contact applications. It can be used as an industrial hose or sleeve if certain chemical resistance is required offered by materials as EPDM or Nitrile.

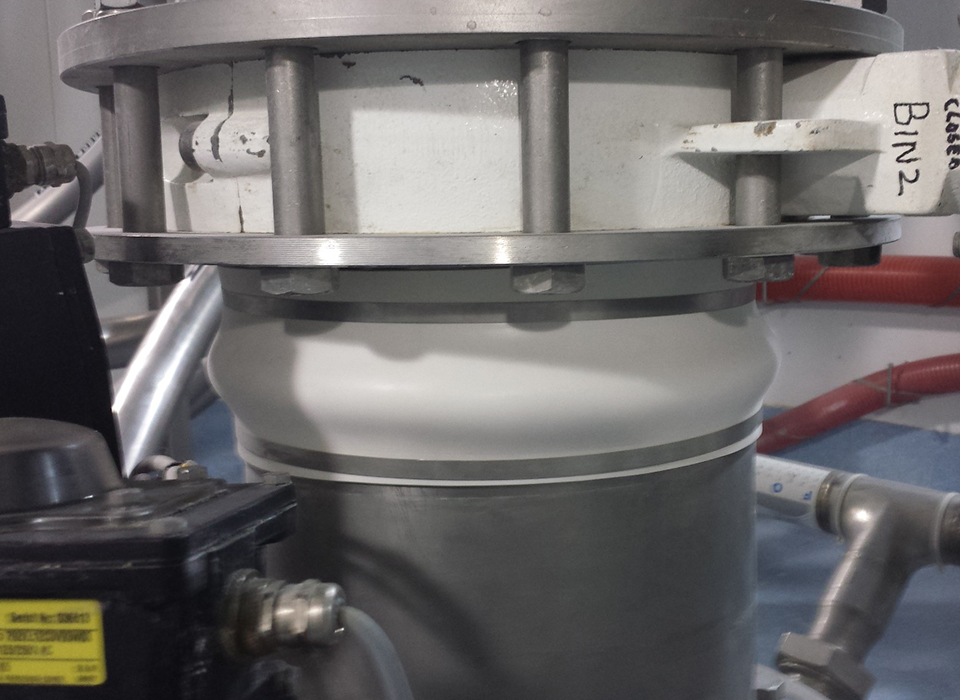

Seamless hose is a quick and easy way to connect pipes or moving machine parts to form a soft connection. Soft connections and Sleeves are required to absorb vibrations, oscillation, axial compression and vibrating movements of powder handling equipment.

Seamless Rubber Tubing comes in a great variety of diameters. The rubber has a good stretch capacity and will allow stretch to fit larger tube sizes up to 5 or 10% larger will not damage the rubber hose.

Every production facility often has a great variety of sleeve lengths but mostly use standardised diameters. Seamless Rubber Hose can be put on stock in standardised diameters and can be cut to the required length. This reduces the amount of different sleeve lengths you have on stock, and therefor reduces stock value levels greatly. Simply cut the required length of the seamless hose and stretch it to the right diameter.

Mechanics and OEM on site engineers benefit during testing and troubleshooting of existing or new to be commissioned machinery. They can easily cut the seamless hose and test these trial sleeves to size for an optimal equipment performance. Once the machine runs perfectly the right size hoses or sleeve can be ordered. These rolls or industrial seamless rubber hose are easily kept in vans, trucks and on site stock rooms.

Seamless rubber tubing is ideal to make emergency repairs, simply cut the right length sleeve and place it in your material handling process.

Most often these hoses are fitted on tubes using a hoseclamp or screwclip. The hose clamps can be adjusted to any tightness. Due to the softness of the rubber hose the hoseclamp can easily compress the rubber to form a 100% seal. Seamless rubber industrial hose can be used on round, rectangular or oval ducting if the standard diameters match the duct circumference.

Materials

Natural Gum rubber FDA

Crude natural gum rubber is found in the juices of many plants (shrubs, vines, and trees), the principal of which is the Hevea Brasiliensis tree, native to Brazil. After the latex is processed, natural rubber becomes an elastomer with excellent mechanical properties.

Advantages:

Natural gum rubber is a best seller for dry bulk material handling. Excellent abrasion resistance.

Extremely elastic and has a great elongation without permanent deformation, which makes it very suitable for machinery with a large movement / displacement.

Natural rubber has excellent tensile, elongation, tear resistance, resilience, and electrical insulation.

Natural rubber has low compression set. good flexing qualities at low temperatures, better than most synthetics, but not as good as silicone. Natural rubber has superb abrasion resistance.

Limitations:

Natural rubber deteriorates when exposed to oils, fuels, solvents, petroleum derivatives, and hydraulic fluids. Without special additives, natural rubber has poor resistance to sunlight, oxygen, ozone, and high temperatures.

| Hardness | 40° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -40°C to 80°C / -40°F to 176°F |

| Tensile to Break | 3000 PSI minimum ASTM D412 |

| Elongation to Break | 500% minimum ASTM D412 |

| Specific Gravity | 1.05 g/cm3 |

| Compliancy according to | FDA |

EPDM

There are two basic types of EP rubber available in today’s market—EP and EPDM. EP is a copolymer of ethylene and propylene, while EPDM is a terpolymer combining ethylene, propylene and a diene monomer. EP uses a peroxide cure system. EPDM uses a sulphur cure system.

Advantages:

Great solvent resistance. Good resistance to weather aging, oxygen, ozone, UV exposure, sunlight, water, steam and heat.

EPDM has an outstanding chemical resistance to dilute acids, polar materials such as phosphate ester base hydraulic fluids, oxygenated solvents (acetone, methyl, ethyl ketone, and other ketones.), alcohol. animal and vegetable oils, alkalis and compression set.

EPDM’s dynamic and mechanical properties are, in general, between natural rubber and SBR.

Limitations:

Poor resistance to petroleum oils, fluids, or solvents because significant swelling would result.

Poor resistance to aromatic hydrocarbons (e.g., benzol, toloul) and aliphatic hydrocarbons (e.g., kerosene, turpentine).

EPDM White FDA

| Hardness | 60° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -40°C to 120°C / -40°F to 248°F |

| Tensile to Break | 1500 PSI minimum ASTM D412 |

| Elongation to Break | 700% minimum ASTM D412 |

| Specific Gravity | 1.25 g/cm³ |

| Compliancy according to | FDA |

EPDM Black

| Hardness | 65° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -40°C to 120°C / -40°F to 248°F |

| Tensile to Break | 1000 PSI minimum ASTM D412 |

| Elongation to Break | 500% minimum ASTM D412 |

| Specific Gravity | 1.13 g/cm³ |

| Compliancy according to |

White Nitrile FDA

Nitrile, or Buna-N, is a copolymer of butadiene and acrylonitrile. It is a general purpose oil-resistant polymer.

Advantages:

Nitrile has excellent resistance to oil, gasoline, solvents, mineral and vegetable oils, hydraulic fluid, and fuels. It is recommended for applications that require good oil and grease resistance as well as moderate ozone resistance. Nitrile is superior to most elastomers with regard to compression set or cold flow, tear and abrasion resistance. Nitrile resists acids and bases with the exception of those having strong oxidizing effects. Nitrile is resistant to a broader range of aromatic hydrocarbons than neoprene. Resistance to heat aging is good.

Limitations:

Nitrile has poor resistance to ketones, chlorinated hydrocarbons, and nitro hydrocarbons. It does not have good ozone, oxygen or sunlight resistance without the addition of special additives.

Nitrile’s low-temperature resistance is inferior to natural rubber.

Tear resistance is inferior to that of natural rubber and electrical insulation is lower.

| Hardness | 60° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -40°C to 120°C / -40°F to 248°F |

| Tensile to Break | 1000 PSI minimum ASTM D412 |

| Elongation to Break | 300% minimum ASTM D412 |

| Specific Gravity | 1.4 g/cm³ |

| Compliancy according to | FDA |

Neoprene Black

Neoprene was created in 1930 by DuPont as an air and oil resistant substitute for natural rubber. It was the first mass-produced synthetic rubber. Neoprene is a polymer of chloroprene and is considered a general or all-purpose rubber.

Advantages:

Neoprene is known for its versatility. It provides good resistance to moderate exposure to ozone, sunlight, oxidation, weather, oils, gasoline, greases, solvents, petroleum oils, animal and vegetable oils, compression set, silicone oil, refrigerants, ammonia, carbon dioxide, water, and steam.

The tear resistance is equal to natural rubber at room temperature; at elevated temperatures tear resistance is poor. Resilience and abrasion strength are good.

Limitations:

The cost of neoprene is its greatest disadvantage. It is a good multipurpose rubber, but there are other types that offer much better oil, ozone, weather and oxidation resistance at a lower cost when they are used for specific applications. Neoprene has poor resistance to strong oxidizing acids, esters, ketones, chlorinated, aromatic, and nitro hydrocarbons.

| Hardness | 62° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -35°C to 120°C / -30°F to 250°F |

| Tensile to Break | 1500 PSI minimum ASTM D412 |

| Elongation to Break | 250% minimum ASTM D412 |

| Specific Gravity | 1.33 g/cm³ |

| Compliancy according to |

Black FKM Viton

FKM is a family of fluorocarbon-based fluoroelastomer materials defined by the ASTM International standard D1418, while it is called FPM by ISO 1629 (both first ed. 1995 and ed. 2013).

It is commonly called fluorine rubber or fluoro-rubber.

All FKMs contain vinylidene fluoride as a monomer.

Originally developed by DuPont (under the brand name Viton, now owned by Chemours), FKMs are today also produced by many companies.

Fluoroelastomers are more expensive than neoprene or nitrile rubber elastomers.

They provide additional heat and chemical resistance. FKMs can be divided into different classes on the basis of either their chemical composition, their fluorine content, or their cross-linking mechanism.

Properties:

Fluorelastomers provide excellent high temperature and aggressive fluids resistance when compared with other elastomers, while combining the most effective stability to many sorts of chemicals and fluids as oil, diesel, ethanol mix or body fluid.

The performance of fluor elastomers in aggressive chemicals depends on the nature of the base polymer and the compounding ingredients used for molding the final products.

Some formulations are generally compatible with hydrocarbons, but incompatible with ketones such as acetone and methyl ethyl ketone, ester solvents such as ethyl acetate, amines, and organic acids such as acetic acid.

They can easily be distinguished from many other elastomers because of their high density of over 1800 kg/m3, significantly higher than most types of rubber.

| Hardness | 55° Shore A +/-5° ASTM D2240 |

| Temperature Resistance | -40°C to 204°C / -40°F to 400°F |

| Tensile to Break | 1300 PSI minimum ASTM D412 |

| Elongation to Break | 300% minimum ASTM D412 |

| Specific Gravity | 1.89 g/cm³ |

| Compliancy according to |

Pressure Resistance

All standard Filcoflex seamless rubber hose is designed for atmospheric applications, with an absolute maximum pressure of 0,3 Bar / 4.3 PSI depending on the diameter and sleeve length.

Filcoflex can do pressure test on positive and negative pressures for your required length and diameter upon request. Testing methods are water pressure test, air pressure tests, all at room temperature. Of each ordered test a test report will be made.

Custom made designs

Depending on your design and application Filcoflex is also able to have custom made pressure resistant hoses built. By adding inner ply layers of polyester or even stainless steel, a hose can be made more pressure resistant. Custom rubber compounds are available upon request. For these seamless custom built hoses there is a minimum order quantity requirement. Special tools or mandrels may be required to be able to build your hose. Please contact our team and they will give you the best recommendations, they will advise if we already have a product that is suitable for your requirement without any minimum production limit.

Dimensions

Available Thicknesses

- 1,6mm / 1/16th Inch

- 3,2mm / 1/8th Inch

- 4,8mm / 3/16th Inch

Available Lengths

- 3,6 meters / 12 foot (standard)

- 7,2 meters / 24 foot (upon request)

Standardised Diameters

| Mm | Inch |

| 50,8 | 2 |

| 63,5 | 2.5 |

| 76,2 | 3 |

| 101,6 | 4 |

| 114,3 | 4.5 |

| 127 | 5 |

| 139,7 | 5.5 |

| 152,4 | 6 |

| 165,1 | 6.5 |

| 177,8 | 7 |

| 203,2 | 8 |

| 219,075 | 8.625 |

| 228,6 | 9 |

| 254 | 10 |

| 273,05 | 10.75 |

| 304,8 | 12 |

| 323,85 | 12.75 |

| 330,2 | 13 |

| 355,6 | 14 |

Related Filcoflex Products

Seamless Rubber Tubing is also available with other connections than hoseclamps, and can also be used to make inflatable bulk bag seals. It can also be made with metal end connections such as:

Jacob Flexible Connections

- FDM – pressed on stainless steel flanges: Jacob / KMH / NORO / S&W / Truduct

Tri-clamp Flexible Connections

- LFR – pressed on stainless steel tri-clamp flanges

- Most used standards Tri-clover standards

- DIN 32676 / BS 4825pt3 / ISO1127 / ASME BPE

Hoseclamps

- KLB09

- KLB20

- KLB25

Inflatable Bulk Bag Clamp

- Seamless Rubber replacement bladders

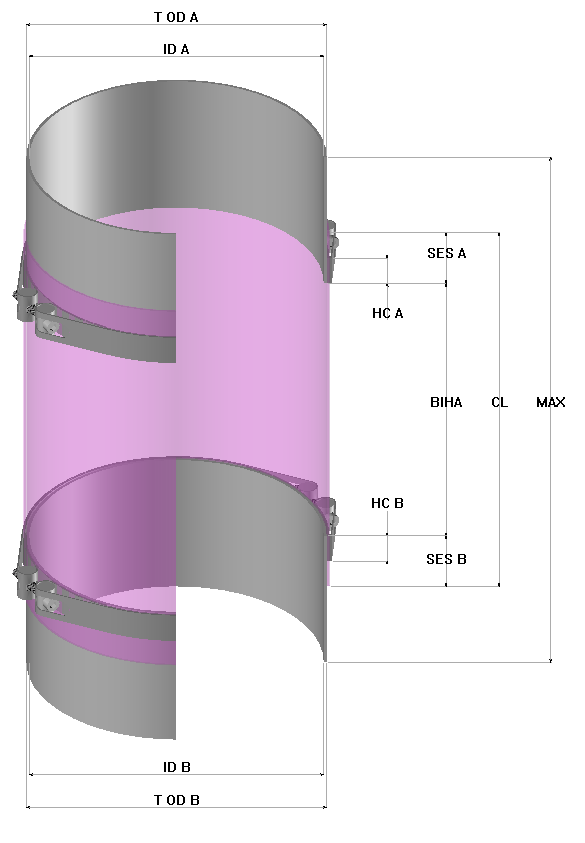

| Parameter | Explanation |

| T OD A | Tube Outside Diameter side A |

| ID A | Inside Diameter side A |

| HC A | Hoseclamp width side A |

| SES A | Straight End Sleeve side A |

| CL | Connector Length (total) |

| BIHA | Length between Tubes / Flanges |

| MAX | Maximum available build in height |

| SES B | Straight End Sleeve side B |

| HC B | Hoseclamp width side B |

| ID B | Inside Diameter side B |

| T OD B | Tube Outside Diameter side B |