PTFE Cross Laminated Films

Filcoflex B.V.’s PTFE Cross Laminated Films are 100% PTFE material that is guaranteed corrosion and contamination free, resists tearing, and has superior flexing capabilities compared to other PTFE products. PTFE Cross Laminated Films can be heat-sealed and is unaffected by UV exposure or moisture.

Because this is an all-PTFE product with excellent mechanical capability and multi-directional strength, PTFE Cross Laminated Films do not require and compromising reinforcement. Regardless of chemical exposure, PTFE Cross Laminated Films remain corrosion free and non-flammable. PTFE Cross Laminated Films is proven in laboratory and industrial settings its ability to retain all its physical properties regardless of chemical environment.

Filcoflex B.V.’s PTFE Cross Laminated are created using a crossed multi directional pattern typically created from 0.07mm or 0,10mm film plies to produce a material with exceptional 360° tear strength and durability. Because PTFE Cross Laminated Films consist solely of PTFE resins, the product is considered chemically inert and can be used in high temperature applications, depending upon the thickness of the Film used.

PTFE Cross Laminated Films has an unlimited shelf life and is compatible with all chemicals. Available in various standard colors, black electric conductive versions, and various thicknesses.

General properties

| Description | Poly Tetra Fluor Ethylene |

|---|---|

| Operating Temperature | -60 °C to 300 °C -76 °F to 572 °F |

| Max. Surge Temp | 316 °C / 600 °F |

| Chemical Resistance | Considered to be nearly Chemically inert |

| Type of Material | Sheet on roll, 1200 (+/- 20mm) x 6000mm (custom on request) |

| Material | 2105 | 2109 Bl/Gr | 2110 | 2112 AS | 2120 AS | 2120 TRA | 2130 | 2140 | 2150 | 2160 |

| Colour | various | Bleu + Grey | various | Black | Black | Translucent | Bleu | White | various | various |

| Weight (gr/sqm) | 272 | 457,8 | 544 | 598 | 1088 | 1088 | 1632 | 2175 | 2727 | 3264 |

| Thickness (mm) | 0,13 | 0,23 | 0,26 | 0,30 | 0,51 | 0,51 | 0,76 | 1,02 | 1,27 | 1,60 |

| Tensile Strength (N/50mm) | 205 | 223,4 | 350 | 357,5 | 778 | 778 | 1135 | 1475 | 1734 | 2510 |

| Tear Strength (N) | 80,1 | 99,8 | 156 | 158,8 | 295 | 295 | 372,1 | 500 | 658 | 1089 |

| Hardness (°Shore A) | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 | 96 |

Pressure Resistance for Flexible Connectors

0,34 Bar / 5.0 PSI For temperatures up to 90 °C / 195°F. Please see “Operating Pressure Guide” for further information. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

ATEX & Explosion Safety

Explosion Pressure: no tests have been performed, this can be done upon request.

Electrostatic Surface Resistance:

-

- PTFE2112 AS Black FDA: < 106 Ohm – Conductive

- PTFE2120 AS Black FDA: < 106 Ohm – Conductive

- PTFE2120 Translucent FDA: > 1,8 x 109 Ohm – Insulating

- Sleeve Length: < 100mm

Airspeed not important

= Powders MIE* > 1mJ

- Sleeve Length: 100 – 1000mm

Airspeed > 2m/s

= Powders MIE* >1000mJ

Airspeed < 2m/s = Powders MIE* >10mJ

- Sleeve Length: < 100mm

*MIE means Minimum Ignition Energy

Despite being insulating the material has been tested, to which relation it can be used in powder and dust transportation system. The relation between airspeed, maximum sleeve length and Minimum Ignition Energy of the powder or dust has been well documented in a report so that PTFE2120 can be implemented in explosion hazardous environments if designed within described parameters.

Name of the reports:

- ‘9075, Report Suitability flexibles 2015 Filcoflex 02.pdf’

- ‘TL9075TestReport_Filcoflex_original.pdf’

Both reports are available upon request.

Chemical Resistance

- CIP resistant (see CIP chemicals guide)

- Cleaning Chemicals (see cleaning guide)

- For a detailed chemical resistance please see our chemical compatibility chart

PTFE films of other thicknesses or colors have not been tested thus far.

Food Contact Compliancy

Filcoflex B.V. hereby declares that below mentioned list (1) of PTFE Cross Laminated Films comply with the following regulations (2) for repetitive contact with food and foodstuffs.

PTFE Cross Laminated Films (1):

- PTFE 2109 Blue/Gray

- PTFE 2112 AS Black

- PTFE 2120 AS Black

- PTFE 2120 Translucent

- PTFE 2130 Blue

List of regulations to which the product complies (2)

FDA 21 CFR of the United States of America:

- 177.1550

- 177.3297

European Union:

- (EC) 1935/2004

- (EC) 10/2011

- (EC) 2003/11

- (EC) 2005/59

Other regulations:

- REACH (SVHC)

- ROHS

Free of substances

None of the following chemicals is intentionally added to PTFE cross Laminated Films, and are there for suspected to not be present in the PTFE material.

- Polyvinyl Chloride (PVC)

- Phthalates

- Melamine

- Silicone

- Latex

- BSE / TSE

- Animal Derived Ingredients (Blood, carrion, pork, animal slaughtered without mentioning the name of Allah/God, wild animal/carnivore, animal with sharp teeth and claws, amphibia)

- Khamr

- Part of Human body

- Peanuts and products thereof

Migration Testing Reports

No migration testing reports are available at this moment

Production methods used

Joining / Bonding:

- Hot Bar Sealing / Welding

Bonded by PFA film as an adhesion / reaction layer between the PTFE layers - No Glue or chemicals are used

Thermo Forming:

- Hot bar bending / High pressure vacuum thermos forming

Cutting:

- Stainless Steel knives

- Water Jet

- Not Suitable for laser cutting

Availability for shapes, couplings and product features

PTFE film can be custom made in to many flexible sleeve and many other products. This document summarizes all the different shapes, end couplings and product features that are available for this flexible material.

Please find detailed explanations on the information pages about these subjects:

- product features & options

- shapes & forms

- coupling ends

Related Filcoflex Product Shapes & Forms

Rectangular – Rectangular

000 / 001 / 002 / 003 / 004

Rectangular – Round

051 / 052 / 053 / 054

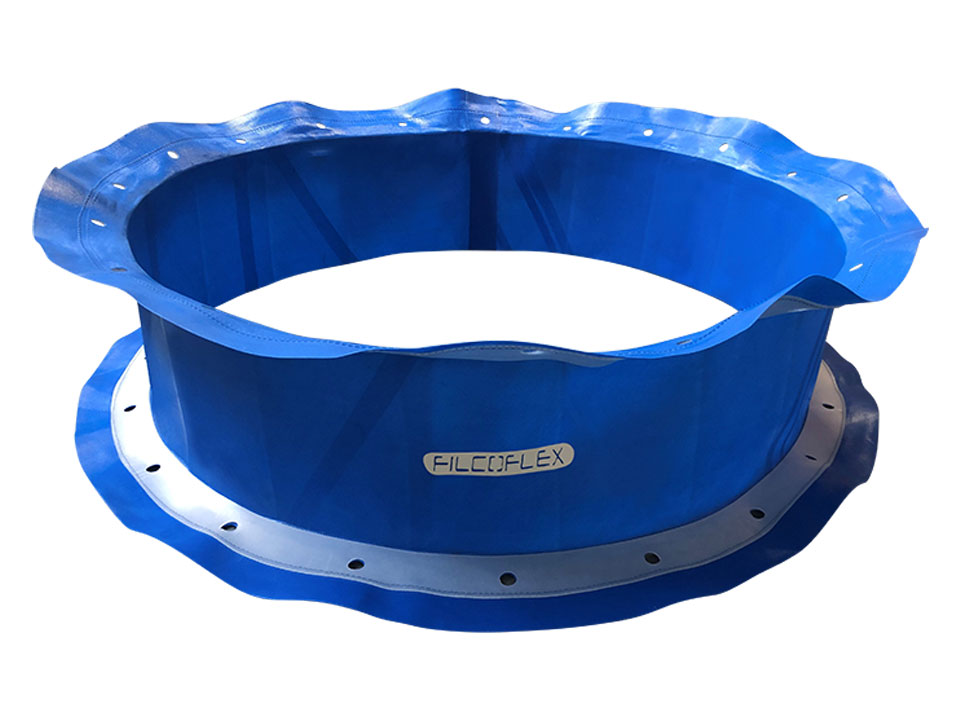

Round – Round

550 / 551 / 552 / 553 / 554

Oval – Oval

660 / 661 / 662 / 663 / 664

Round – Oval

651 / 652 / 653 / 654

Related Filcoflex Product Coupling Ends

Jacob Flexible Connections

Flexible Connectors

Innovative seals

- Spray Shields

- Protection Covers

Hoses

- PTFE Hose On Roll

Sheets

- Cut sheets and pattern

Related Filcoflex Product Features & Options

Sleeve within a Sleeve

- Inside Cone / Inside Sleeve (7)

Padding on Flange or Cuff

Double Wall Flexible

- Double layer flexible sleeve body (6)

Label

- NFC chip encased in Poly Urethane pocket

- Printed label encased in Poly Urethane pocket. Can contain customized Text, Bar code, QR code.

3 optional colors (yellow/blue/white)

**pocket will be stitched to the end of the sleeve or flange