Advantages

- Excellent flexibility

- Superior mechanical strength

- Axial and Lateral (vertical and horizontal)

- compression 2:1

- Big Bag (Bulk Bag) charging / discharging

- Superior abrasion resistance

- Translucent

- Smooth welded seams

- Great aging resistance

- Nonporous

- No material degradation

- Explosion Safety Certified gases, liquids, and dust

- ATEX 2014/34/EU (1999/92/EC)

- TRGS 727

- Food Contact Compliant

- FDA, (EC)1935/2004, 10/2011, 2015/174

- Wide range of diameters

- Wide range of end connections available

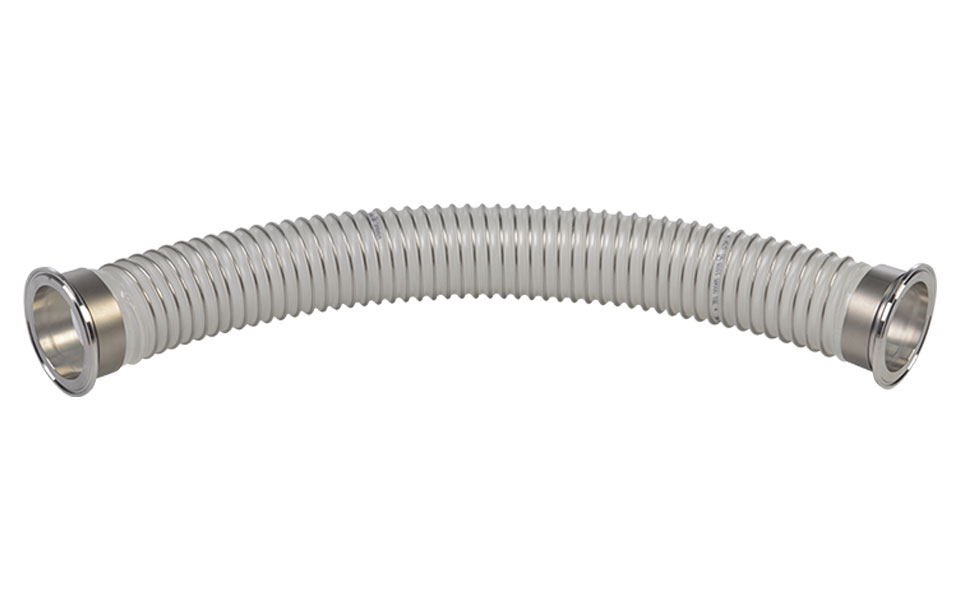

Spiral Hose Poly Urethane Antistatic Food Contact Compliant Inox spiral Robust – Bends

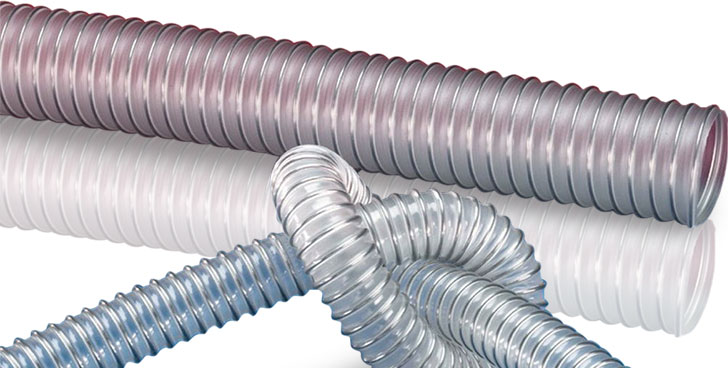

Flexible spiral reinforced hose/ducting for transport of explosion hazardous abrasive dust, powder, fibers, air, gasses, and liquids. This hose is tested to be suitable for direct contact with food and pharmaceutical products, such as sugar, milk powder, rice, cereals, coffee, chocolate, grains, tea, flour, frozen foods. This hose is suitable for explosion hazardous environments due to its electrostatic conductive properties. The hose can be used for extraction arms, long distances to connect tubing machinery or components.

The 3:1 compressible ratio allows for telescopic features such as big bag handling stations. The Poly Urethane material is suitable for contact with food according to American and European food contact regulations, the spiral reinforcement is made in Stainless Steel. The metal spiral reinforcement allows for great harmonica like telescopic compressible features. Due to the spiral the folds are consistent, and no irregular pleads will form, preventing material fatigue.

Applications

Harmonica’s, Telescopic applications, big-bag, bulk-bag emptying / discharging, charging and emptying handling equipment, long hoses, dust extracting arms, Stationary, Vibratory, Gyratory, Sifters, Screeners, Feeders, Spray driers, Fluid Bed, Static Cool Bed, Bin dischargers, Hoppers, Conveyors, Packing equipment, Storage silos, Screw conveyors, Valves, butterfly valves, Rotary valves, Tanks, Silo’s, any sort of product handling equipment, Air ducting, Fans, Inflatable seals, Covers, Outside protection sleeves, Bellows, Load cell (high volume, weight, and capacity), ATEX zones 20,21,22, 0,1,2 gasses, dusts, and liquids.

General properties

| Name | Spiral 10 AS Food Inox Airduc PUR-INOX 351 FOOD-AS |

| Description | Poly Ether Urethane |

| Color | Translucent |

| Surface | Matt (both sides) |

| Wall Thickness | 1,00mm / 0.0393 Inch (+/-20%) |

| Compressible | 2:1 |

| Operating Temperature | -40 °C to 90°C -40 °F to +194 °F |

| Max. Surge Temp | +120 °C / +248 °F |

| Low Temperature Flexibility | Good |

| Air Permeability | 0 |

| Type of Material | Spiral Hose |

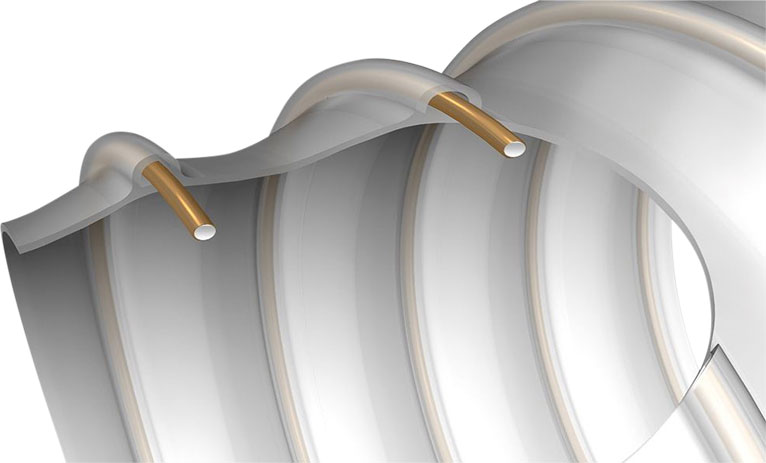

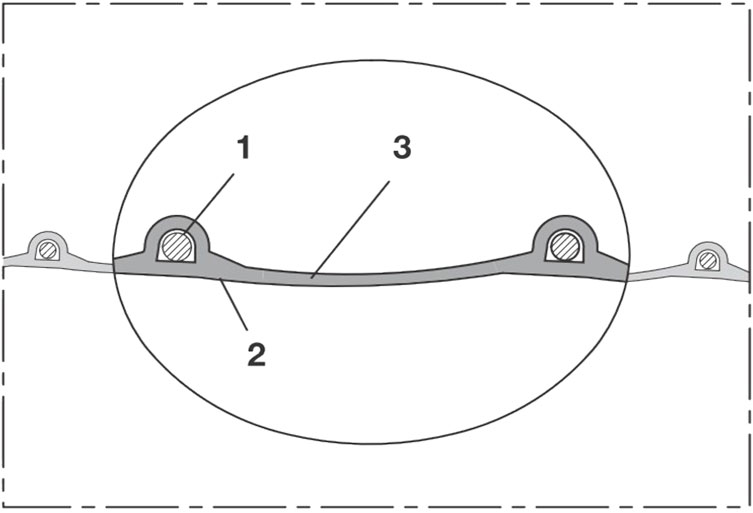

| Spiral Reinforcement | DIN 1.4404 / AISI 316 L |

| Wire Diameter | 1.6mm / 1/16th Inch |

Available diameters and pressure resistance

| Ø mm |

Ø Inch |

Ø OD Inch |

Pressure Bar DIN26057 |

Vacuum Bar DIN26057 |

Bending Radius mm |

Minimum Length M |

| 25 | 1 | 33 | 2.640 | 0.680 | 22 | 5 / 10 |

| 32 | 1.25 | 40 | 2.090 | 0.440 | 28 | 5 / 10 |

| 38 | 1.5 | 46 | 1.775 | 0.370 | 32 | 5 / 10 |

| 40 | 48 | 1.690 | 0.355 | 33 | 5 / 10 | |

| 50 | 2 | 58 | 1.365 | 0.285 | 39 | 5 / 10 |

| 60 | 2.36 | 68 | 1.145 | 0.235 | 45 | 5 / 10 |

| 64 | 2.5 | 73 | 1.055 | 0.220 | 48 | 5 / 10 |

| 70 | 79 | 0.985 | 0.145 | 52 | 5 / 10 | |

| 75 | 3 | 84 | 0.920 | 0.135 | 55 | 5 / 10 |

| 80 | 89 | 0.865 | 0.125 | 58 | 5 / 10 | |

| 89 | 3.5 | 99 | 0.770 | 0.110 | 64 | 5 / 10 |

| 100 | 4 | 109 | 0.695 | 0.105 | 70 | 5 / 10 |

| 110 | 119 | 0.630 | 0.095 | 76 | 5 / 10 | |

| 125 | 5 | 134 | 0.555 | 0.085 | 85 | 5 / 10 |

| 140 | 4.5 | 149 | 0.500 | 0.075 | 94 | 5 / 10 |

| 150 | 6 | 159 | 0.465 | 0.075 | 100 | 5 / 10 |

| 160 | 6.3 | 169 | 0.435 | 0.070 | 106 | 5 / 10 |

| 178 | 7 | 189 | 0.390 | 0.060 | 118 | 5 / 10 |

| 200 | 8 | 209 | 0.350 | 0.055 | 133 | 5 / 10 |

| 225 | 9 | 234 | 0.310 | 0.040 | 145 | 5 / 10 |

Overpressure and under pressure are recommended threshold operating values, products can be subject to higher loads upon request. The bending radius is measured through the inside of the hose arch. The right to make technical modifications is reserved. All values determined at 20°C and are approximate data.

ATEX & Explosion Safety

Permanently antistatic wall in accordance with ISO 8031 electrical and surface resistance < 109 Ω and in accordance with TRGS 727 <2.5*108 Ω.

In accordance with ATEX 2014/34/EU (1999/92/EC) and German TRGS 727: pneumatic transport of flammable dusts and bulk combustible materials (zone 20, 21, 22), aspiration of combustible dusts (Zone 22 inside), for conveying for flammable liquids (inside zone 0,1,2), for conveying for non-flammable liquids, for use in zone 1 and 2 (gases), for use in zone 0 (gases).

Test Report

Optional crimped on terminal lug with a Ø5.5mm hole.

Optional Quick Connect earthing connectors.

Food Contact Compliancy

This product complies with the following regulations for plastics in repetitive contact with foods:*

All compliances to regulations have been approved by an independent testing laboratory for the complete hose according to:

- United States

- FDA 21 CFR 177.2600

- European Community

- (EC) 1935/2004

- (EC) 10/2011

- (EC) 2015/74

- (EC) 2023-2006

Tested with food simulant E.

*Some restrictions may apply, a copy of all certifications can be downloaded, or will be sent to you upon request. We will be happy to advise further if you have any questions.

Other compliances

In accordance with GMP EC 2023/2006. Conforms to RoHS guideline.

Test Report

Resistance

- Odorless and tasteless

- Microbe and hydrolysis resistant

- Good resistance to: oil, gasoline, and chemicals

- Very good low temperature flexibility.

- CIP resistant (see CIP chemicals guide)

- Cleaning Chemicals (see cleaning guide)

- For a detailed chemical resistance please see our chemical compatibility chart

Weighing Applications

Suitable for high volume and weight, weighing and dosing applications.

Production Methods used

- Welding

- HF high frequency welding

- Welding the material and cooling it down under compression with Radio Frequency to make the TPU material flow nearly seamless to form a uniform thickness with the original material wall thickness.

- Heat contact – with silver alloy heating element

- Welds are welded surface to surface after which the weld are compressed while cooling.

- Hot air – hot filtered and conditioned contaminent-, oil- and grease- free compressed air