EPDM Antistatic Black FDA 65° Shore A (EPDMas)

Filcoflex B.V.’s EPDMas is an EPDM antistatic black FDA 65° Shore A is a rubber material sheet from rolls. EPDMas is used for a number of purposes, to cut custom gaskets and to make flexible sleeves among other things.

EPDMas is an electro antistatic EPDM rubber. The rubber is black because carbon is added to the EPDM raw material before extruding it in to sheet material. The addition of carbon makes the EPDM rubber dissipative for electricity, this prevent the electrostatic charging of the sleeve or gasket made from this sheet material. The sheet is a roll material, the roll are 1200mm wide and have 10 meter length.

EPDM has a good solvent, acid and alkali resistance, and a good general chemical resistance. EPDM has a higher temperature resistance than most plastics (e.g. Poly Urethane) or natural rubbers.

General properties

| Name | EPDMas black antistatic FDA |

|---|---|

| Description | Ethylene Propylene Diene Monomer rubber with added Carbon for electric conductivity |

| Hardness | 65 ° Shore A (+/- 5°Shore tolerance) |

| Tear Resistance | 14,4 N/mm2 |

| Color | Black |

| Specific Weight | 1,11 – 1,13 g/cm3 |

| Maximum Elongation | 240% |

| Post Curing of sheet material | Peroxide cured |

| Electrostatic Resistance | |

| Volume Resistivity | <2,5 x 107 Ohm*cm DIN IEC 60093 |

| Surface Resistivity | <3.3 x 106 Ohm*cm DIN IN 100 015/1 |

| Operating Temperature | -30 °C to 130 °C -22 °F to 266 °F |

| Air Permeability | 0 |

| Type of Material | Sheet on roll, 1200mm (+/- 20mm) x 10000mm |

Pressure Resistance for Flexible Connectors

0,34 Bar / 5.0 PSI For temperatures up to 90 °C / 195°F. Please see “Operating Pressure Guide” for further information. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

Weighing Applications

High volume weight and capacity weighing and dosing applications please see “weighing and dosing guide” for further information.

Chemical Resistance

- Good temperature resistance

- Good ozone resistance

- Very good acid resistance

- Very good alkali resistance

- Good CIP resistance

- Good weather resistance

- Poor oil resistance

- Poor petrol resistance

ATEX & Explosion Safety

Explosion Pressure: no tests have been performed, this can be done upon request.

Electric Resistance: EPDM antistatic black FDA in 2mm and 3mm are antistatic sheet materials with a surface resistance lower than 10^5 Ohm.

Test Conditions

Temperature: 21 °C

Electrical insulation meter: NIEAF SMITT IRT-C

Measurement Voltage: 100 Volt

Tested Material: EPDM Antistatic Black FDA

Thickness: 2mm and 3mm

Food Contact Compliancy

Filcoflex B.V. hereby declares that below mentioned list (1) of EPDM rubbers comply with the following regulations (2) for repetitive contact with food and foodstuffs.

EPDM rubbers (1):

- EPDM Antistatic Black FDA 2mm

- EPDM Antistatic Black FDA 3mm

List of regulations to which the product complies (2)

FDA 21 CFR of the United States of America:

- 170 – 199 CFR §

- 177.2600 (e)

- 177.3297

European Union:

- N.a.

Other regulations :

- KTW D1-D2 hot and cold water

- DBL 5556.21

- VW 2.8.1G65

- 2005/68/EG

- 3A hygiene standards, Class III

for repetitive contact with foodstuffs for Rubber and rubber-like materials.

Free of substances

None of the following chemicals is intentionally added to EPDM antistatic black FDA (EPDMas), and are there for suspected to not be present in the material.

- PAK

- Phthalates

- Nitrosamine

- Silicone

- Sulfur

- BSE / TSE

Production Methods used

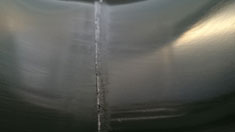

Joining / Bonding:

All seams are overlapped seams, the ends are made thinner before they are overlapped. The overlap seam has a thickness within that has a +1mm -0.5mm tolerance compared to the original material thickness.

*seams are grinded before they are glued for a better adhesion

Cutting:

- Stainless Steel knives

- Water Jet

Availability for shapes, couplings and product features

EPDM Black Antistatic FDA 65° Shore A can be custom made in to flexible sleeves and number other products. This document summarizes all the different shapes, end couplings and product features that are available for this flexible material.

Please find detailed explanations on the information pages about these subjects:

- product features & options

- shapes & forms

- coupling ends

Related Filcoflex Product Shapes & Forms

Rectangular – Rectangular

000 / 001 / 002 / 003 / 004

Rectangular – Round

051 / 052 / 053 / 054

Round – Round

550 / 551 / 552 / 553 / 554

Oval – Oval

660 / 661 / 662 / 663 / 664

Round – Oval

651 / 652 / 653 / 654

Related Filcoflex Product Coupling Ends

Jacob Flexible Connections

Flexible Connectors

Hoses

- Rubber Hose On Roll (HOR)

Up to 2000mm long

Seals, Gaskets and Covers

- Cut sheets or patterns

- Gasket cut from sheet

Related Filcoflex Product Options

Integrated Reinforcement rings

To withstand vacuum collapse or over pressure expansion.

- Stainless Steel, 3mm / 5mm / 8mm (VR)

- PE 6x10mm poly ethylene (VRPE)

- Stainless Steel T bar 20x25x3 (VRT)

Padding on Flange or Cuff

Label

- NFC chip encased in Poly Urethane pocket

Stitched on to the end of the EPDM product - o Printed label encased in Poly Urethane pocket

3 optional colors (yellow/blue/white)

Stitched on to the end of the EPDM product - RFID chip encased in Poly Urethane pocket

Stitched on to the end of the EPDM product