Features

- Standard Sizing (length & diameter)

- Large diameter range

- Fits Imperial and Metric tubing

- Minimal influence on Weighing process

- New conical bellow design for hygiene

- Available with quick connect couplings

- Antistatic version available

- Soft Silicone

- Always on stock

- Air, gas and fluid-proof

- Permanently elastic and break-resistant

- Decoupling of vertical oscillations

- Aging resistant

- Compensation of oscillations or external forces

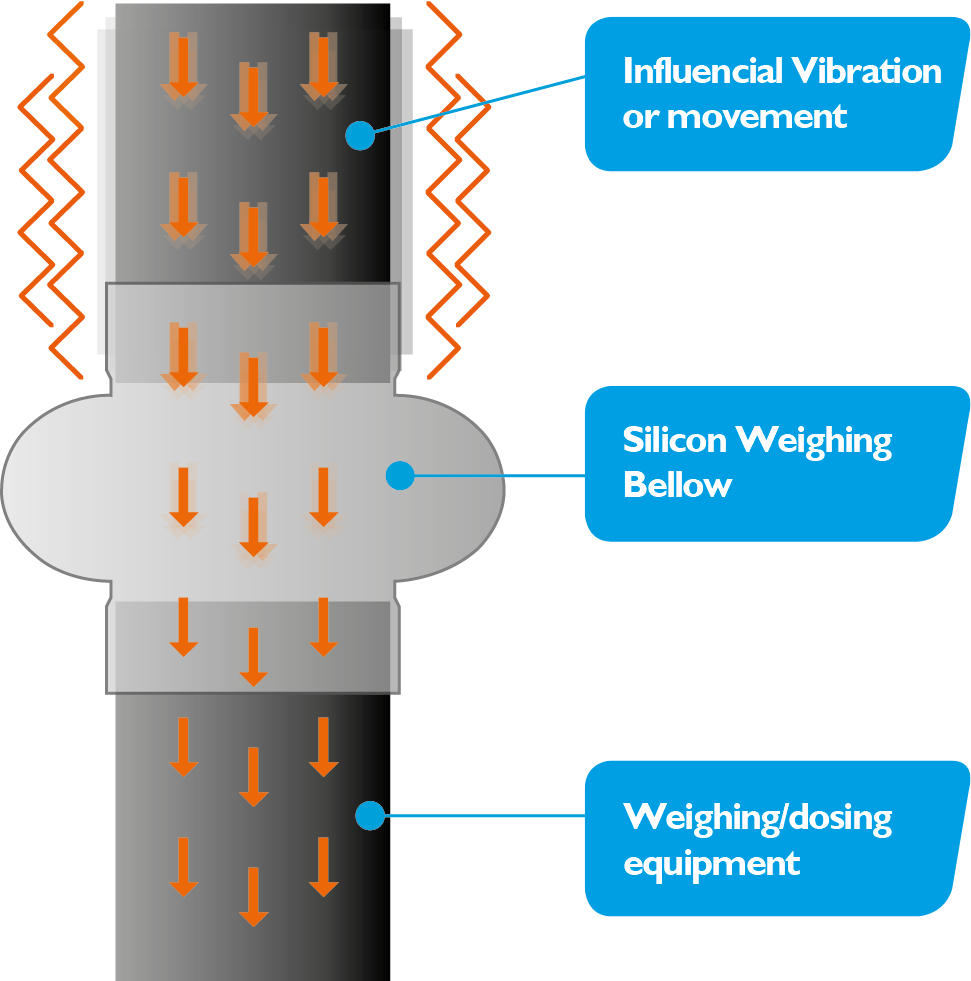

Silicone Weighing Bellows

Weighing Bellows serve to create a flexible connection between dosing equipment, mixers, feeders or vessels on weighing- / Load cells to supply lines, drain pipes, packaging equipment or other forms of air or powder transport. Accurate batch sizes are crucial to ensure a high quality end product. Silicone Weighing Bellows suit most machines of well-known OEM manufacturers.

Clean workplaces and reproducible product quality are of the greatest importance, and are a prerequisite for long-term employee and customer retention. A small component such as the Filcoflex weighing bellow, can play an absolutely decisive role in attaining these goals when handling dusty bulk materials. Often, “unclean” product-carrying weighing system facilities mean that frictional connections form which influence the scale and falsify the weighing result.

Many so-called compensators are much too stiff or even permeable; they certainly do not compensate for oscillations or external forces. Especially with materials which are a hazard to health, this leads to safety-relevant aspects which urgently require attention. The Filcoflex silicone weighing bellow permanently and reliably eliminates these weak spots.

The many benefits with regard to permanent elasticity, aging resistance, suitability for use with foodstuffs, temperature resistance and the highest flexibility, make it an essential weighing technology component. In addition, it is a popular choice as vibration decoupling for dosing channels, and as a connecting element between system components.

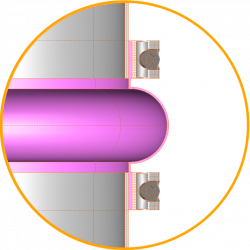

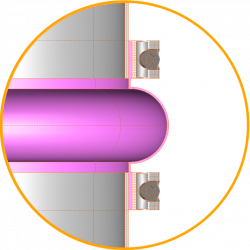

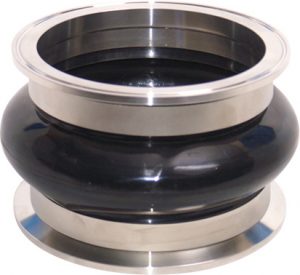

Filcoflex weighing bellows are available in a spherical and asymmetrical conical bellow shape, and possess excellent mechanical properties for decoupling vertical oscillations. Weighing Bellows in the classical round bellow shape have been designed to transfer minimal influence such as vibration or movement from the feeding or receiving equipment to the weighing or dosing equipment.

Advantages

- Air- & dust-tight

- Easy to clean

- Extremely flexible

- Optimal product flow

- Removes influence on weighing processes

- Standardized sizes

- Universal diameter range

- Permitted for use with foodstuffs

- FDA 21 CFR 177.2600

- (EC) 1935/2004

- Also available with Quick Detach coupling

Big Diameter Range

Silicone Weighing Bellows allow enough stretch to fit imperial size tubing aswell as metric size tubing. If your diameter is slightly larger than the standardized diameters the bellows will stretch enough to compensate the difference even if both sides are not connected to the same tube size.

Silicone Weighing Bellows White

Weighing Bellows serve to create a flexible connection between dosing equipment, mixers, feeders or vessels on weighing- / Load cells to supply lines, drain pipes, packaging equipment or other forms of air or powder transport. Accurate batch sizes are crucial to ensure a high quality end product. Silicone Weighing Bellows suit most machines of well-known OEM manufacturers.

Weighing Bellows in the classical round bellow shape have been designed to transfer minimal influence such as vibration or movement from the feeding or receiving equipment to the weighing or dosing equipment.

| Name: | Silicone Weighing Bellows Asymmetrical Conical White |

| Description: | Silicone |

| Hardness: | 60° Shore A (+/- 5°Shore tolerance) ASTM D2440, DIN ISO 7619-1 |

| Color: | White / Translucent |

| Elongation to failure: | 240% |

| Temperature Resistance: | -60 °C to 200°C -76 °F to 392 °F |

| Maximum Surge Temperature: | 220 °C / 428 °F |

| Pressure Resistance: | Silicone weighing bellows are meant to be used in atmospheric applications |

Available Diameters

| Article No. | Metric (mm) | Imperial (inch) |

| 801334 | 50 | 2” |

| 801335 | 60 | 2.5” |

| 801336 | 75 | 3” |

| 801337 | 100 | 4” |

| 801338 | 114 | 4.5” |

| 801339 | 140 | 5” |

| 801340 | 150 | 6” |

| 801341 | 168 | 6.5” |

| 801342 | 200 | 8” |

| 801343 | 219 | 8.5″ |

| 801344 | 250 | 10” |

| 801346 | 300 | 12” |

| 801348 | 350 | 14” |

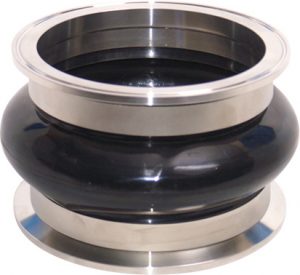

Silicone Weighing Bellows Black Conductive FDA

Silicone Weighing Bellow Conductive are made of a silicone compound to which carbon has been added to make the silicone compound electrostatically conductive and have a resistance lower than <10^6 Ohm. The low electrostatic resistance means light powders do not tend to stick on the surface of the bellow, and electrostatic energy is not able to build up on the surface of the bellow, therefor not creating any explosion hazards which may occur at high capacity powder flow rates and high air speeds.

Properties – Silicone Weighing Bellows Black Conductive FDA

| Name: | Silicone Weighing Bellows Conductive Black FDA |

| Description: | Silicone with added Carbon for electric conductivity |

| Hardness: | 60 ° Shore A (+/- 5°Shore tolerance) ASTM D2440, DIN ISO 7619-1 |

| Color: | White / Translucent |

| Elongation to failure: | 240% |

| Temperature Resistance: | -60 °C to 200°C -76 °F to 392 °F |

| Maximum Surge Temperature: | 220 °C / 428 °F |

| Electrostatic Resistance: | <106 Ohm |

| Pressure Resistance: | Silicone weighing bellows are meant to be used in atmospheric applications |

Available Diameters

| Article No. | Metric (mm) | Imperial (inch) |

| 801355 | 60 | 2.5” |

| 801356 | 75 | 3” |

| 801357 | 100 | 4” |

| 801358 | 114 | 4.5” |

| 801360 | 150 | 6” |

| 801362 | 200 | 8” |

| 801364 | 250 | 10” |

| 801366 | 300 | 12″ * |

* available q4 of 2022

ATEX & Explosion Safety – Silicone Weighing Bellows Black Conductive FDA

| Electric Resistance: | Silicone conductive weighing bellows are made in an electrostatically conductive compound with a surface resistance lower than 10^6 Ohm |

| Test Conditions: | |

| Temperature: | 20 °C |

| Electrical insulation meter: | NIEAF SMITT IRT-C |

| Measurement Voltage: | 100 Volt |

| Tested Material: | Silicone Conductive Black FDA |

| Thickness: | 1mm and 2mm |

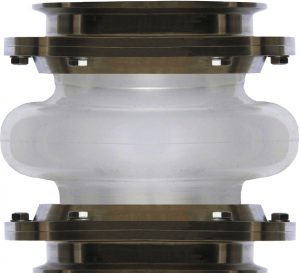

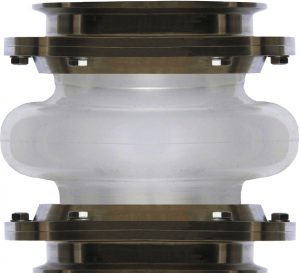

Silicone Weighing Bellows Asymmetrical Conical White

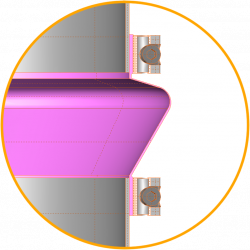

Silicone Weighing Bellows Asymmetrical Conical have the added advantage of the asymmetrical conical design. The angle of the bottom cone is on a 60° angle, which prevents powder collection, piling or blockage inside the bellow shape. No powders can remain within the bellow shape, which is possible with the conventional spherical bellow. The design is specifically made for hygienic applications, and is easier to clean.

Properties – Silicone Weighing Bellows Asymmetrical Conical White

| Name: | Silicone Weighing Bellows Asymmetrical Conical White |

| Description: | Silicone |

| Hardness: | 60 ° Shore A (+/- 5°Shore tolerance) ASTM D2440, DIN ISO 7619-1 |

| Color: | White / Translucent |

| Elongation to failure: | 240% |

| Temperature Resistance: | -60 °C to 200°C -76 °F to +392 °F |

| Maximum Surge Temperature: | 220 °C / 428 °F |

| Pressure Resistance: | Silicone weighing bellows are meant to be used in atmospheric applications |

Available Diameters

| Article No. | Metric (mm) | Imperial (inch) |

| 801374 | 50 | 2” |

| 801375 | 60 | 2.5” |

| 801376 | 75 | 3” |

| 801377 | 100 | 4” |

| 801378 | 114 | 4.5″ |

| 801380 | 150 | 6” |

| 801382 | 200 | 8” |

| 801384 | 250 | 10” |

| 801386 | 300 | 12″ * |

* available q4 of 2022

Silicone Weighing Bellows – Food Contact Compliancy in general

Following independent testing we can confirm that our Silicone Elastomer Weighing Bellows with here under listed Article Numbers comply with the requirements of (EC)1935/2004 that all food contacting materials are “safe” to be used in repetitive contact with foodstuffs.

All of our Silicone Products are manufactured using European ingredients conforming fully to the requirements of REACH legislation. We confirm that our Silicone Products are carefully produced to comply with European Commission Regulations (EC)2023/2006 “good manufacturing practice for materials and articles intended to come into contact with food”.

In the current absence of EU legislation which specifies the requirements to prove that a silicone article is safe for food contact, we have conducted independent extraction testing to the requirements of FDA 21CFR 177.2600 “Rubber articles intended for repeated contact with foodstuff” + The German BfR XV “Food Standard for Silicones” + European Directive 2002/72/CE (UNE-EN 1186: Part 3 (aqueous food simulant) & Part 14 (fatty food simulant).

All of these tests conclude that our silicone rubber materials fully meet tangible food and drink industry extraction levels. In addition they are sufficiently inert to preclude substances being transferred to food in quantities large enough to endanger human health or to bring about an unacceptable change in composition of the food or a deterioration in its organoleptic properties.

Filcoflex B.V. hereby declares that below mentioned list (1) of Silicone weighing bellows in white, conductive black and asymmetrical conical version all comply with the following regulations (2) for repetitive contact with food and foodstuffs.

Silicone Weighing Bellows (1):

- Silicone Weighing Bellows White

- Silicone Weighing Bellows Conductive Black FDA

- Silicone Weighing Bellows Asymmetrical Conical

List of regulations to which the product complies (2)

FDA 21 CFR of the United States of America:

- 177.2600 (e)

European Union:

- (EC) 1935/2004

- (EC) 2023/2006

Migration Testing reports are available on both the White / Translucent Silicone compound for the spherical and the asymmetrical conical weighing bellows, aswell as the conductive black silicone compound for the spherical and asymmetrical conical silicone weighing bellows. All migration testing reports can be supplied with your request and your order.

To ensure and to be able to check afterwards if a batch of silicone bellows is in compliance with the documents and certificates supplied to you Filcoflex has a traceability programme in order. Of each production run samples are stored in containers so that up to 7 years after the production date the samples can be retested and compared in quality of the originally tested batch.

All silicone bellows of which the article numbers are listed in this document are suitable for contact with dry, aqueous and fatty foods defined by the FDA. As stated in 21 CFR 177.2600 it is recommended that the manufactured article is thoroughly cleansed prior to first use in contact with food.

Silicone Weighing Bellows – restriction or abscense of banned substances

Use of Banned Substance in Silicone Elastomer Weighing Bellows. None of the following substances are contained in; or used in the production process of any of the Silicone elastomer Weighing Bellows White Translucent with here under listed article numbers sold by Filcoflex:

Lead (Pb), cadmium (Cd), hexavalent chromium (Cr6+), mercury (Hg), phthalates, Bisphenol A, polycyclic aromatic hydrocarbons (PAH), Short chain chlorinated parafins (SCCP), brominated flame retardants, including polybrominated biphenyl ether, polybrominated diphenyl ether, octabromobiphenyl ether, pentabromobiphenyl ether and decabromodiphenyl ether.

These products and associated production processes are free of any animal derivatives and are latex free. None of the Silicone elastomer Weighing Bellows with here under listed article numbers.contain azodicarbonamide blowing agents. None of the Silicone elastomer Weighing Bellows with here under listed article numbers sold by Filcoflex contain Perfluoro octane Sulfonates (PFOS)

All Silicone elastomer Weighing Bellows White Translucent with here under listed article numbers sold by Filcoflex and their processing methods comply with the substance control requirements of the following directives; (Including amendments issued prior to the date of this statement):

- GADSL (formally known as ILRS List 101 and VDA list 232-101)

- EC Directive 76/769/EC

- EC Directive 2011/65/EC (RoHS)

- EC Directive 2002/96/EC (WEEE)

- EC Directive 2002/95/EC

- EC Directive 2000/53/EC (ELV)

- EC Directive 2003/11/EC

- EC Directive 2006/122/EC

And any subsequent modifications to these core directives released before the date below.

ATEX on SILICONE BELLOWS IN GENERAL

Translucent silicone weighing bellows can be used in explosion hazardous environments / ATEX zones 20, 21 and 22 as long as they are under 100mm length. Translucent silicone weighing bellows are not electrostatically dissipative.

Black conductive silicone weighing bellows can be used in explosion hazardous environments / ATEX zones 0,1,2 because they are electric conductive, as well as ATEX zones 20,21 and 22.

Please check with us for the specific conditions for each type of bellow to be used in your explosion safe design, we will happily provide you with the best recommendation and documentation.

Custom weighing Bellows

Silicone weighing bellows are made in standardized diameters and lengths. From 50pcs of one size they can be made to your design, fitting your required dimensions.

Chemical Resistance of Silicone

Silicone has a great resistance to:

- Ozon

- Aging

- Air

- Gas

- Most fluids

- Oxidadation

- Ultraviolet light (UV)

- Corona discharge

- Cosmic radiation

- Ionising radiation and weathering in general

Silicone has a poor resistance to:

- Oil, oily products, coffee oil

- Gasoline

- Acids

Silicone has an average resistance to:

- Lie

Production Method

All Filcoflex B.V.’s Silicone weighing bellows are compression molded food contact suitable silicone compound.

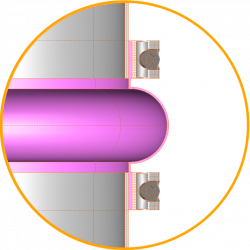

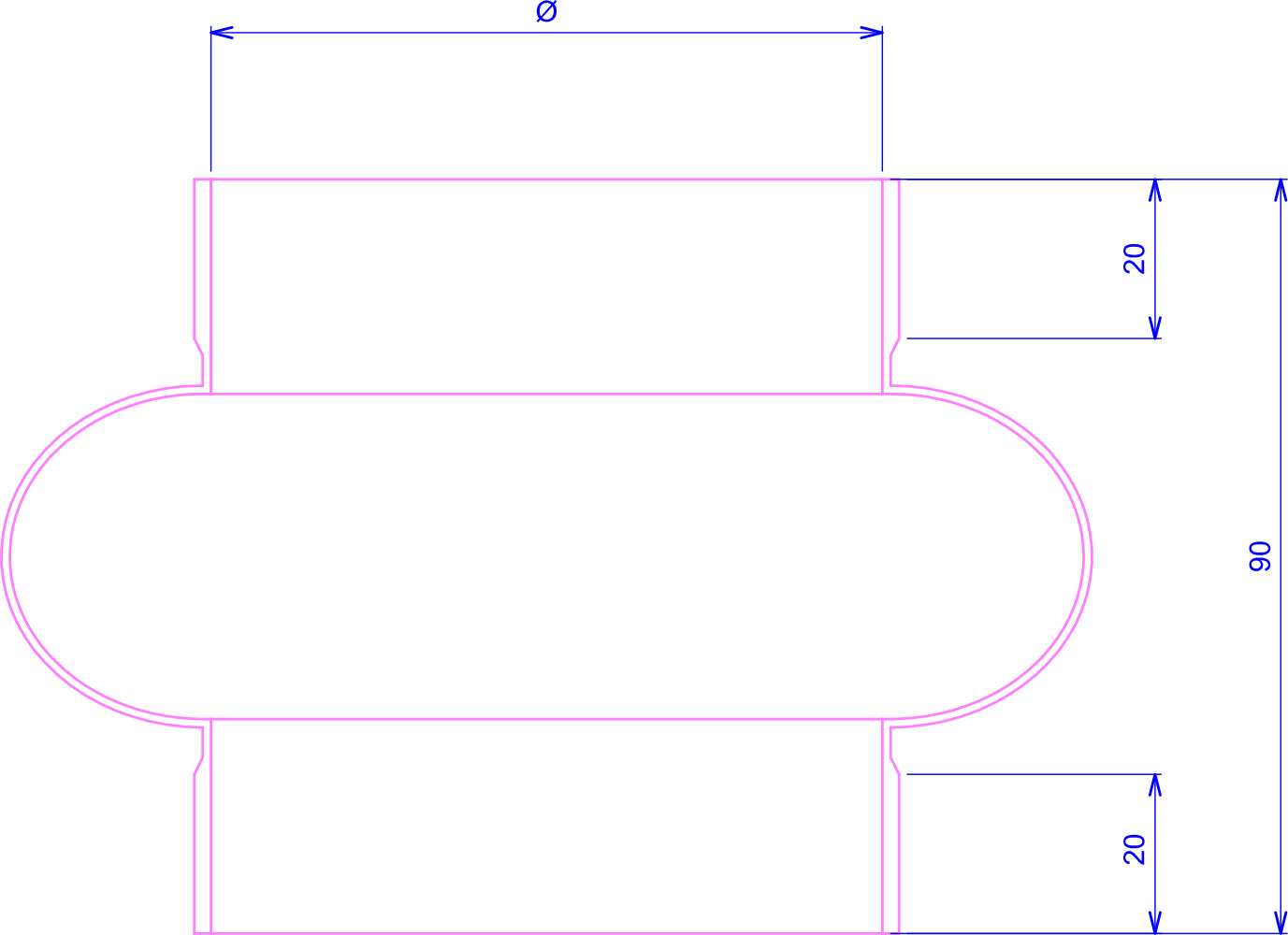

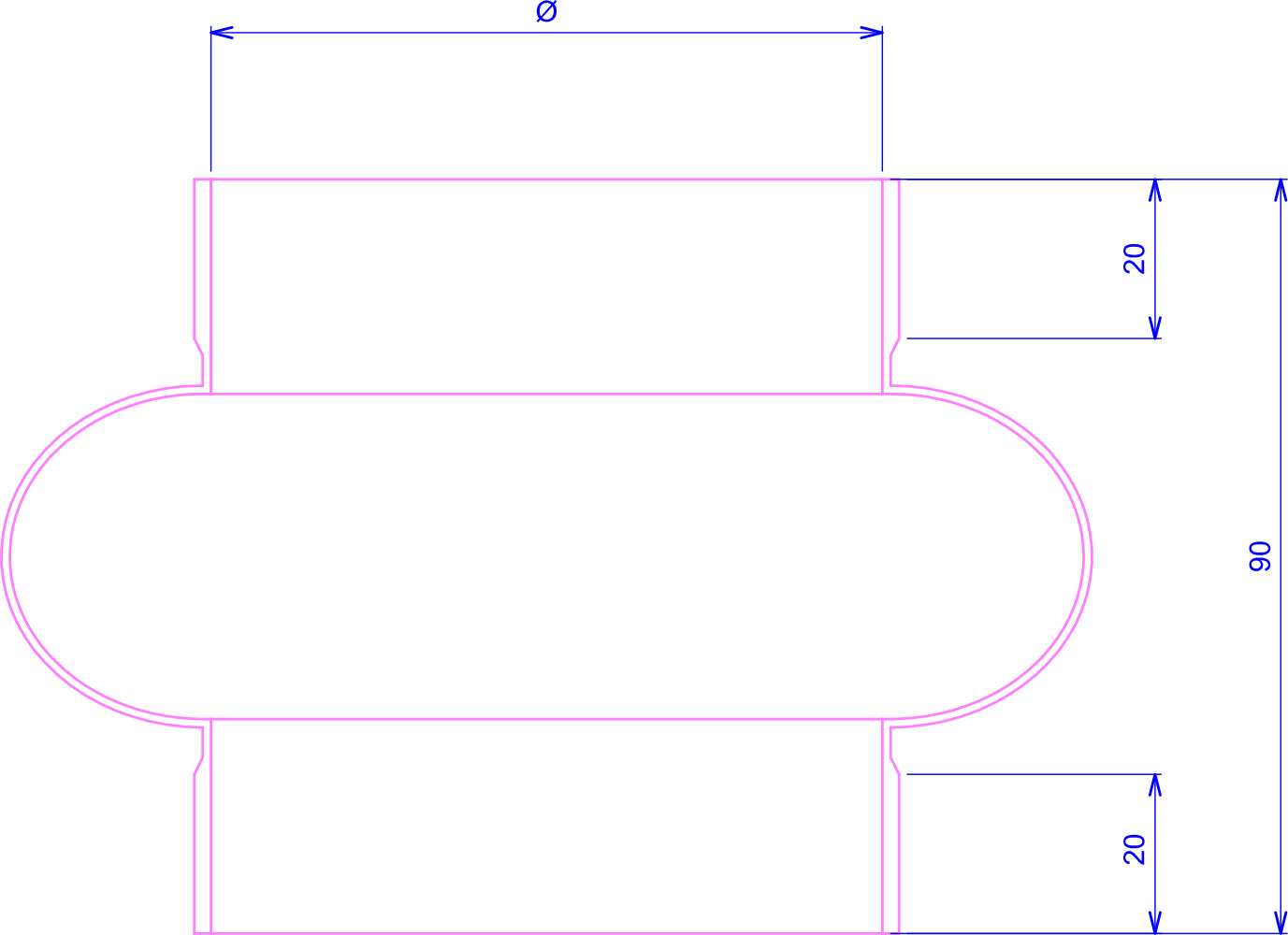

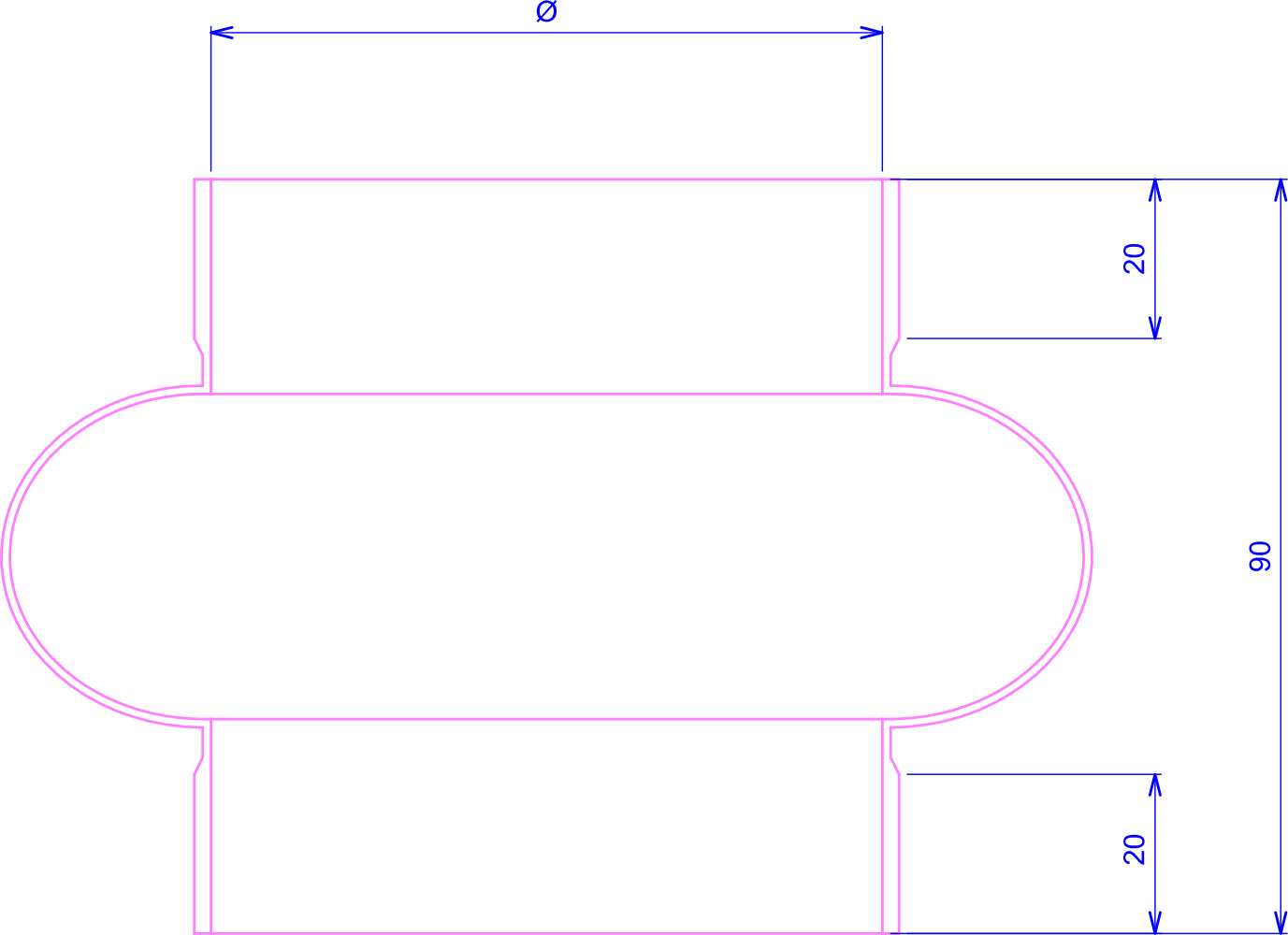

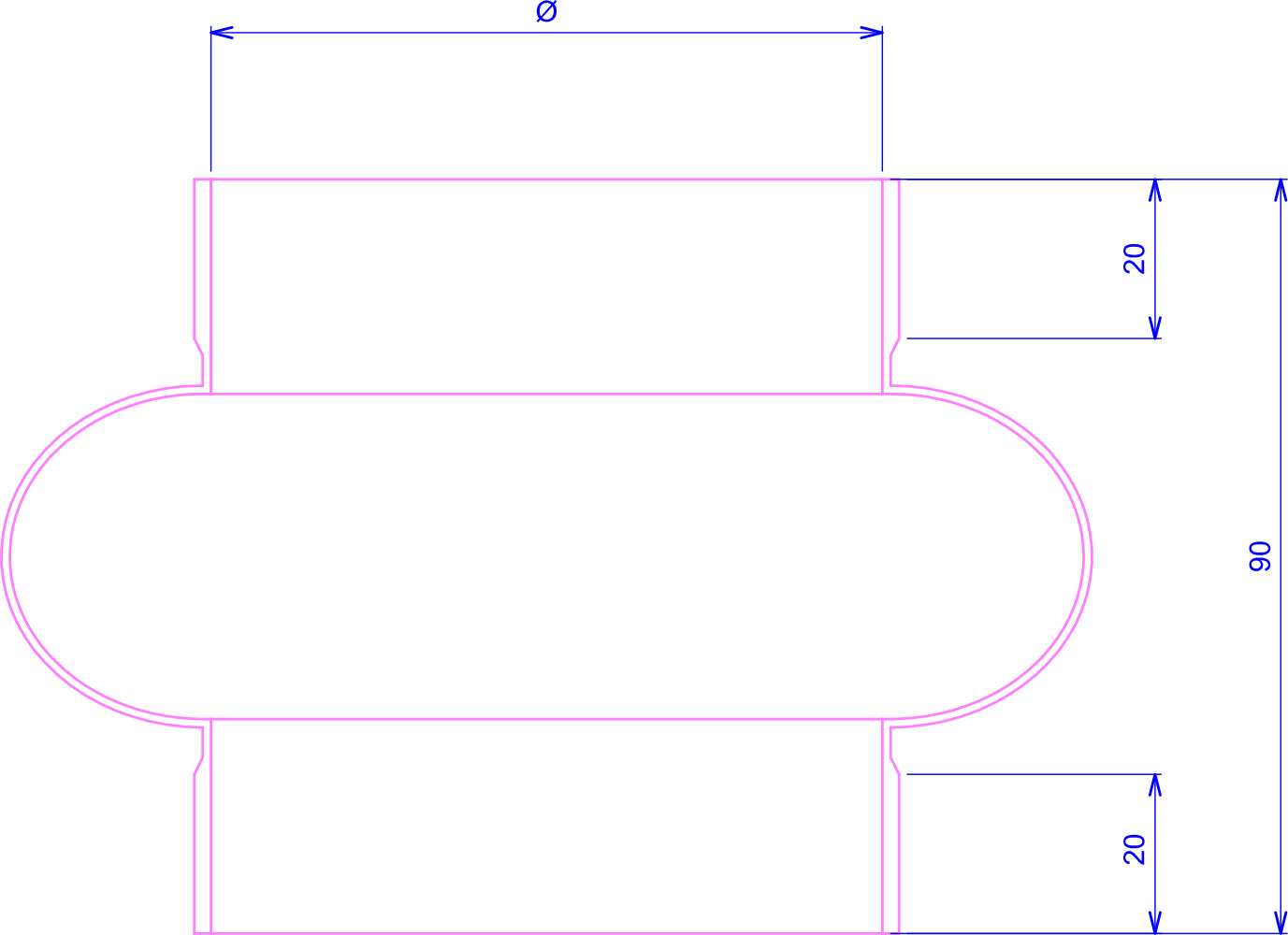

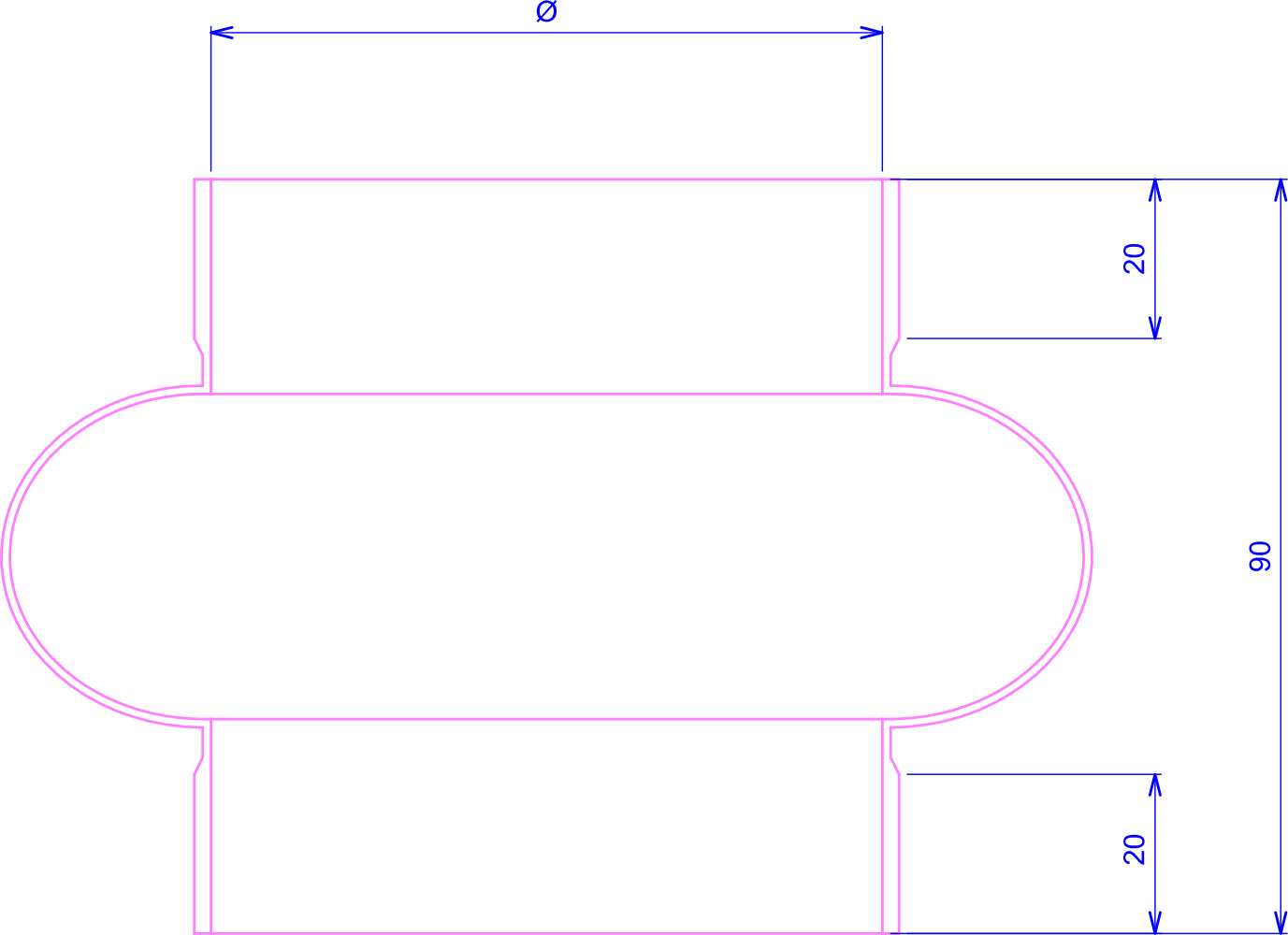

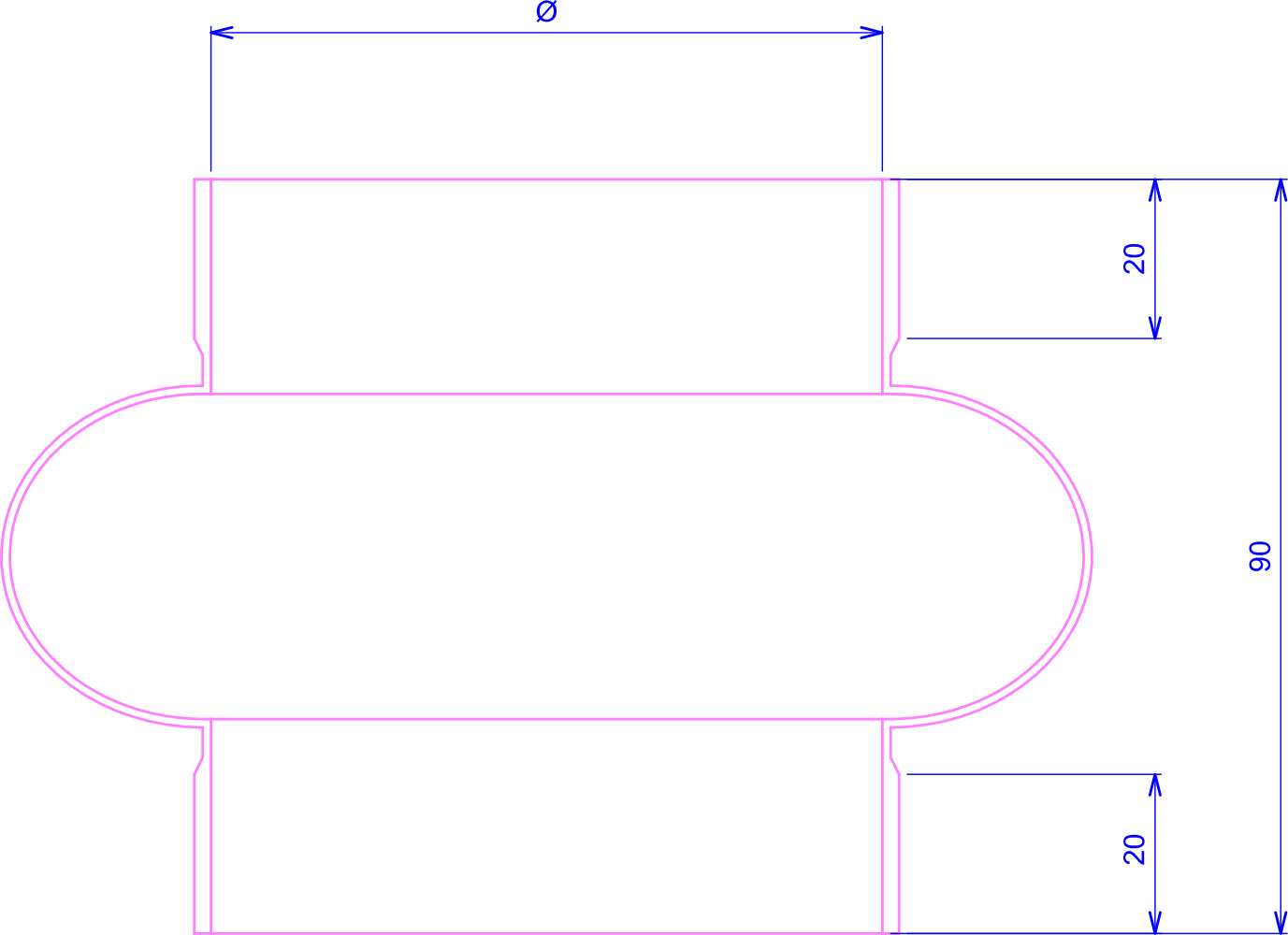

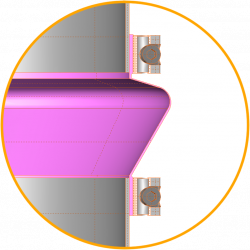

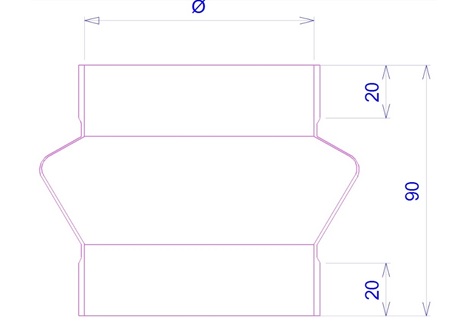

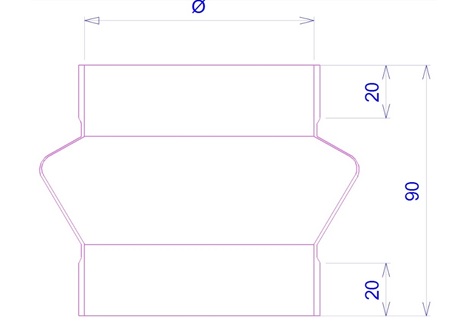

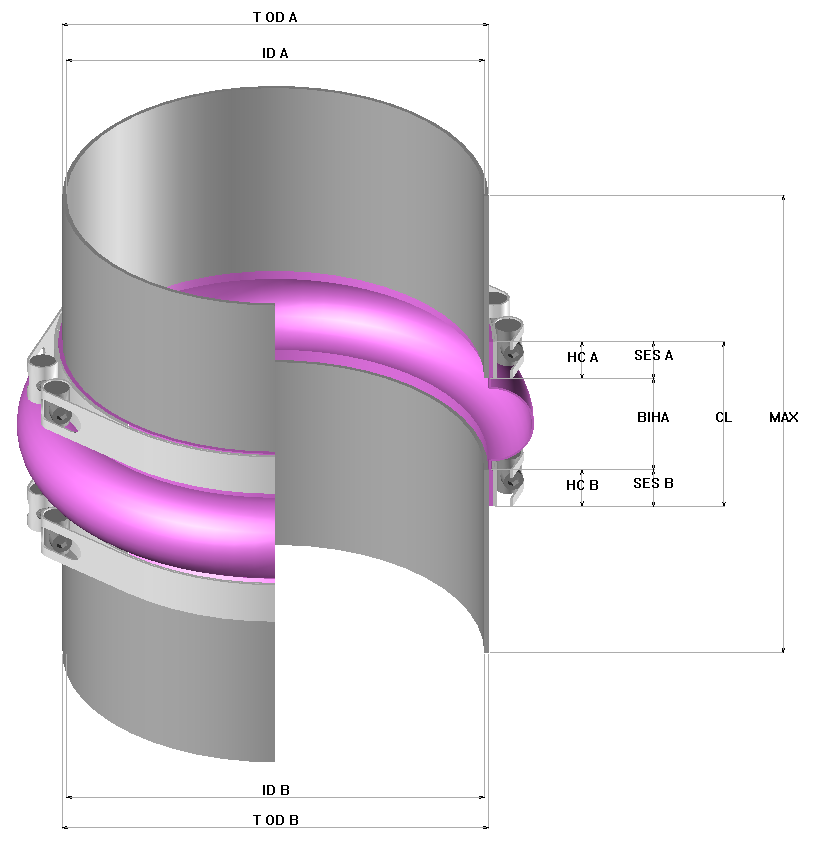

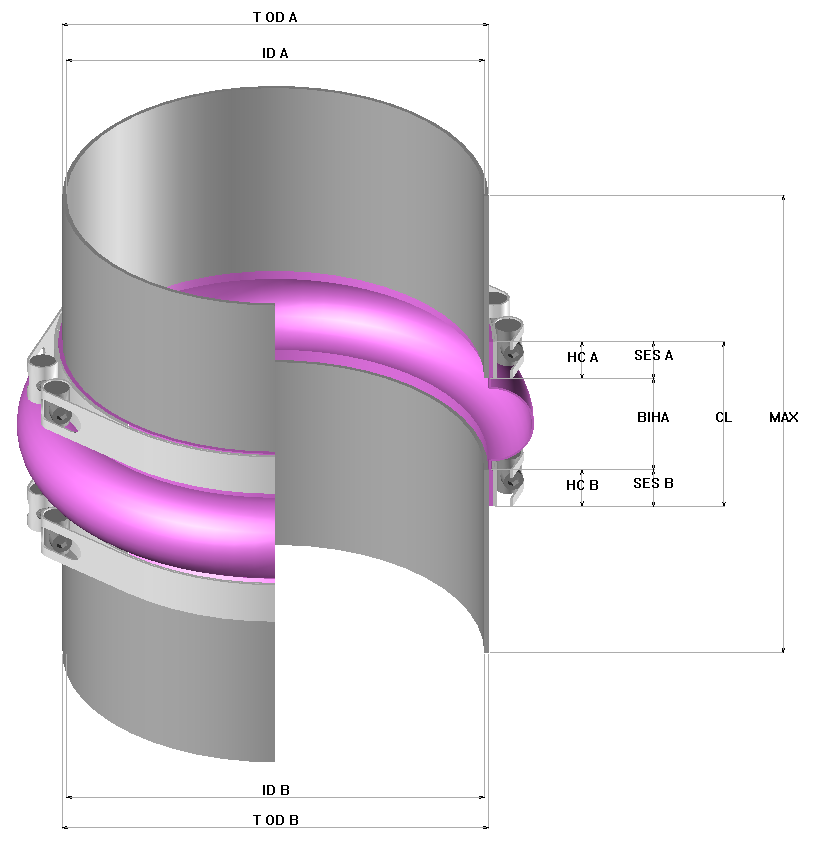

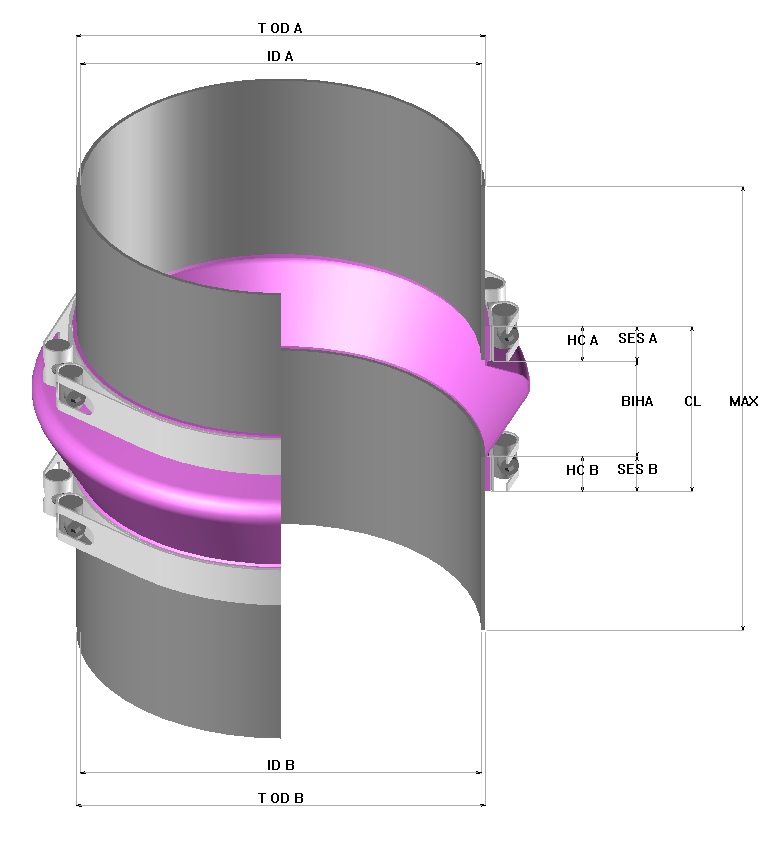

Drawing when in use

Spherical

Asymmetrical Conical

| Parameter | Explanation |

| T OD A | Tube Outside Diameter |

| ID A | Inside Diameter |

| HC A | Hose Clamp width |

| SES A | Straight End Sleeve |

| CL | Length Weighing Bellow |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| SES B | Straight End Sleeve |

| HC B | Hose Clamp width |

| ID B | Inside Diameter |

| T OD B | Tube Outside Diameter |

Related Filcoflex Product Options

Quick Detach Couplings can be assembled on to the standard silicone weighing bellows using the well-known couplings like:

Silicone weighing bellows extended

Jacob coupling

- FDM, pressed on Jacob tubing flanges in either 25mm or 55mm length resulting in a either a 100 or 160mm total length

Tri-clamp coupling

-

- LFR, pressed on Tri-clamp flanges in 28mm length, resulting in an overall length of 106mm

- LFRc, pressed on Tri-clamp flanges with an inside conical milled tube connecting side that reduces any edges on the inside resulting in an even smoother inside bore than the LFR type, Tri-clamp flanges are 28mm length, resulting in an overall length of 106mm

-

- CFL, bolted on conical Tri-clamp flanges for high grade pharmaceutical end users.

Related Products and Recommended Accessories

Quick Detach Couplings can be assembled on to the standard silicone weighing bellows using the well-known couplings like:

KLB20, 20mm Hoseclamps

HECHT Bellow, HECHT TRI-clamp bellow

Poly Urethane Weighing Bellows