Features

- Round

- Rectangular

- Oval

- Round to rectangular

- Conical, misalignment, any other shape

- Hole pattern according to your drawing

- Optional attached flange gasket

- DIN / ANSI flanges

- Custom made flange design

- Custom made sleeve design

- All sorts of flexible materials

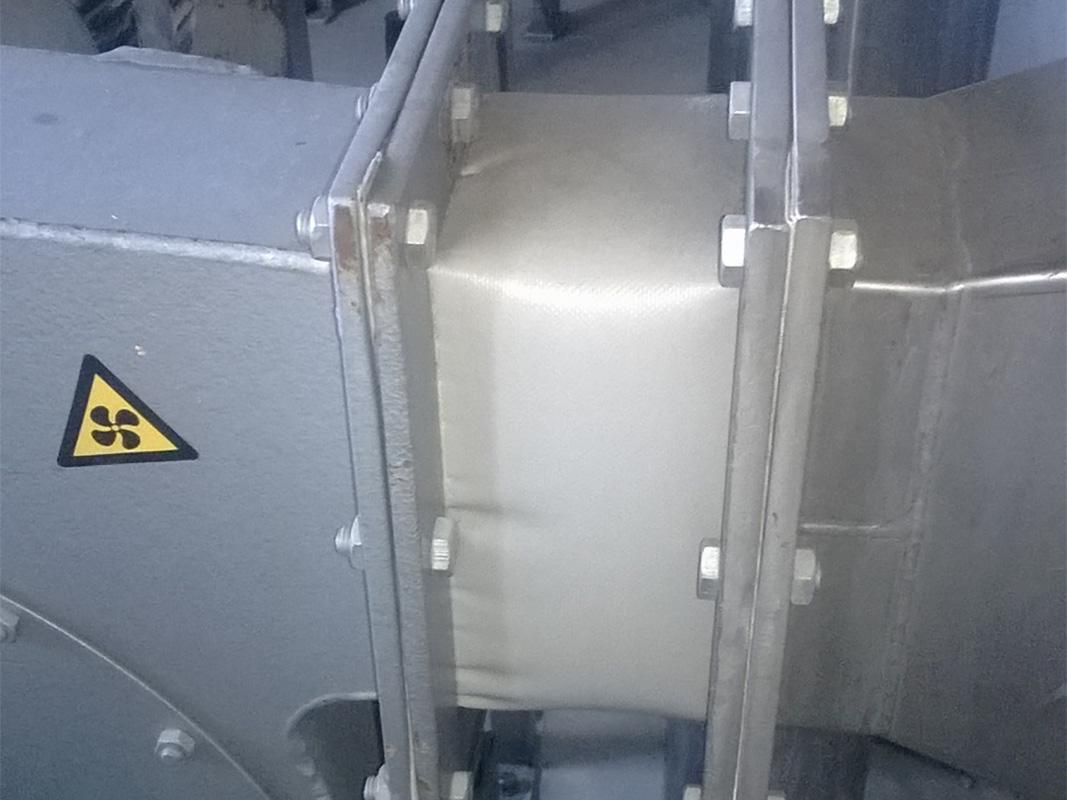

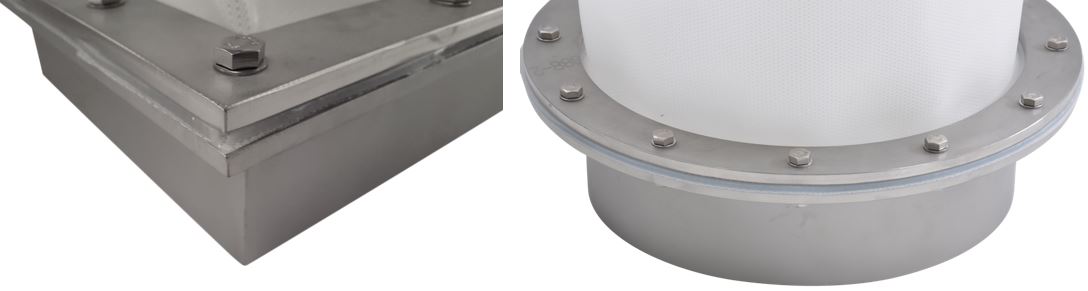

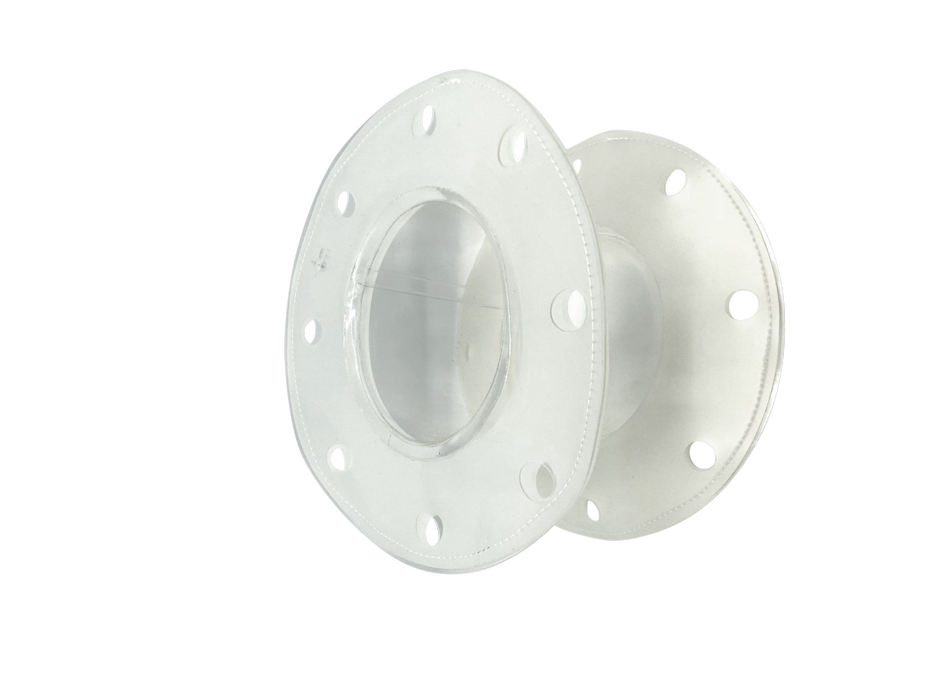

Flange Fitted Flexible connections

A more robust way to connect pipes or moving machine parts is a flexible sleeve that is fitted with flanges. The flange can be designed as round, oval and rectangular in every diameter, circumference, height and length.

Various Connection Styles can be Combined.

- Always airtight and leak free

- Hygienic flow profile

- Reducers / Adapters

- Many different materials, such as;

- Poly Urethane

- EPDM

- Silicone

- Gum rubber

- Nitrile

- PTFE

- Other

- Tailor made / Custom made

- Conical shape, round to rectangular and any other shape

Variations

- Conical

- Eccentric

- Unparallel flange surfaces

- With inner sleeve

- Y piece / side branche / T piece

- Bellow shape, symmetric and conical asymmetric

- Reinforcement rings against vacuum and overpressure (also in grounded editions)

- End cap or blind cover

- Spiral shaped reinforcement

- Many more

Flange Fitted Flexible Connections, if designed correctly, are a very sanitary way of connecting a flexible connection to a tube or duct. Because the entire flange connection is airtight and leak free there can be no contamination between the flanges, making the connections suitable for Clean In Place. Mounting all the nuts and bolts requires more time than any quick connect type of flexible connection. However, the secure way of fitment without leaks and because there can be contamination between the flanges, there is no need to disassemble or take out the flexible for cleaning. It can be done as a precautionary measure, but most users try to disassemble as little as possible. Flange Fitted Flexible Connections are the ideal product for any CIP design and process. Clean In Place works best and suggest to leave as many parts in their function without dismantling.

Flange Fitted Flexible Connections, when using the right flange design, has a smooth flow profile and therefor let’s itself be cleaned easily during CIP and dry out. Also because there is no contamination between the flanges or any leakages, there is no need to disassemble for the CIP procedure. Flange Fitted Flexible Connections makes it a very efficient product, much more than any Quick Connect Flexible, which always need to be checked for leakages.

Advantages

- Air tight

- Pressure resistant

- Easy to assemble

- Robust, hard to damage

- Clean In Place

Materials

Flange Fitted Flexible Connections can be produced in many different materials. For more information please go to our Materials Comparison Table.

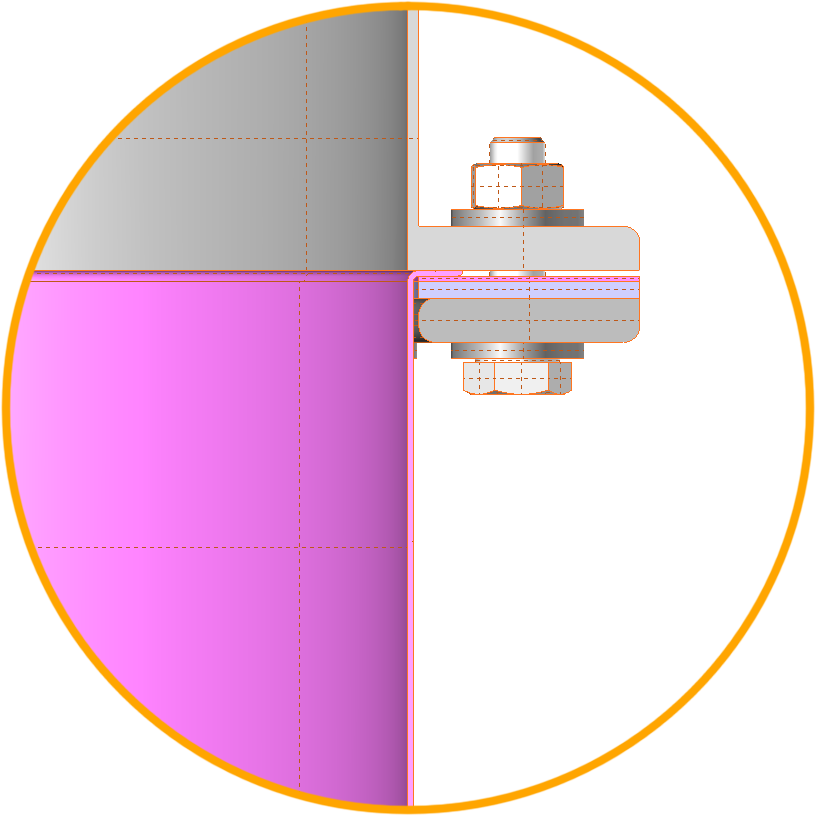

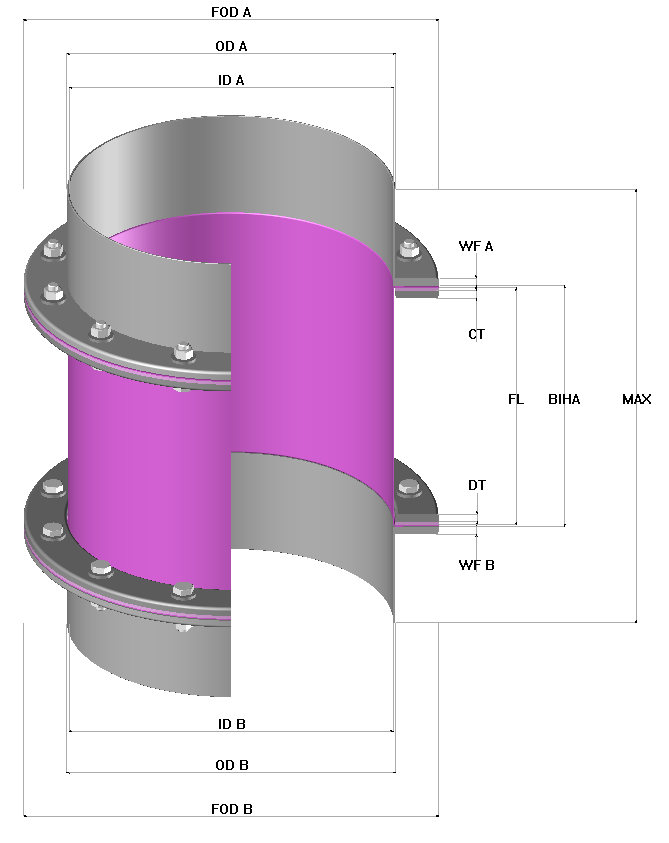

| Parameter | Explanation |

| F OD A | Flange Outside Diameter |

| OD A | Tube Outside Diameters |

| ID A | Inside Diameter |

| WF A | Welding Flange Thickness |

| CT | Counter Flange Thickness |

| FL | Length Flexible Sleeve |

| CL | Length Flexible Connector |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| DT | Counter Flange Thickness |

| WF B | Welding Flange Thickness |

| ID B | Inside Diameter |

| OD B | Tube Outside Diameter |

| F OD B | Flange Outside Diameter |