Neoprene CR/SBR Black 60° Shore A

Filcoflex B.V.’s Neoprene CR/SBR Black 60° Shore A is a rubber material sheet from rolls. Neoprene CR/SBR Black 60° Shore A is used for a number of purposes, to cut custom gaskets and to make flexible sleeves among other things.

The sheet is a roll material, the roll are 1200mm wide and have 10 meter length.

Neoprene was created in 1930 by DuPont as an air and oil resistant substitute for natural rubber. It was the first mass-produced synthetic rubber. Neoprene is a polymer of chloroprene and is considered a general or all-purpose rubber.

Advantages

Neoprene is known for its versatility. It provides good resistance to moderate exposure to ozone, sunlight, oxidation, weather, oils, gasoline, greases, solvents, petroleum oils, animal and vegetable oils, compression set, silicone oil, refrigerants, ammonia, carbon dioxide, water, and steam.

The tear resistance is equal to natural rubber at room temperature; at elevated temperatures tear resistance is poor. Resilience and abrasion strength are good.

Limitations

The cost of neoprene is its greatest disadvantage. It is a good multipurpose rubber, but there are other types that offer much better oil, ozone, weather and oxidation resistance at a lower cost when they are used for specific applications. Neoprene has poor resistance to strong oxidizing acids, esters, ketones, chlorinated, aromatic, and nitro hydrocarbons.

General properties

| Name | PU-UF1 |

|---|---|

| Description | Poly Ether Urethane |

| Color | Clear Transparent |

| Surface | Gloss / Gloss (both sides) |

| Surface Roughness | – |

| Wall Thickness | 1,00mm / 0.0393 Inch (+/-10%) |

| Hardness | 86° Shore A |

| Tensile Strength | 50 MPa |

| Maximum Elongation | 600% |

| Operating Temperature | -40 °C to 90°C -40 °F to +194 °F |

| Max. Surge Temp | +120 °C / +248 °F |

| Low Temperature Flexibility | Good |

| Air Permeability | 0 |

| Type of Material | Sheet on roll, 1500×50000 mm |

Pressure Resistance for Flexible Connectors

0,34 Bar / 5.0 PSI For temperatures up to 90 °C / 195°F. Please see “Operating Pressure Guide” for further information. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

Weighing Applications

High volume weight and capacity weighing and dosing applications please see “weighing and dosing guide” for further information.

Chemical Resistance

- CIP resistant (see CIP chemicals guide)

- Cleaning Chemicals (see cleaning guide)

- For a detailed chemical resistance please see our chemical compatibility chart

ATEX & Explosion Safety

No available data.

Food Contact Compliancy

Not food contact compliant.

Production Methods used

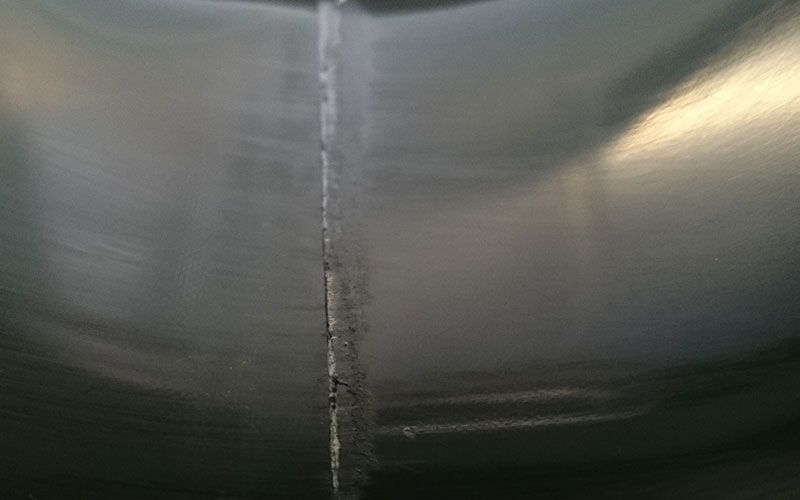

Joining / Bonding:

All seams are overlapped seams, the ends are made thinner before they are overlapped. The overlap seam has a thickness within a +1mm / -0.5mm tolerance compared to the original material thickness.

*seams are grinded before they are glued for a better adhesion

Cutting:

- Stainless Steel knives

- Water Jet