Advantages

- Great solvent resistance. Good resistance to weather aging, oxygen, ozone, UV exposure, sunlight, water, steam and heat.

- EPDM has an outstanding chemical resistance to dilute acids, polar materials such as phosphate ester base hydraulic fluids, oxygenated solvents (acetone, methyl, ethyl ketone, and other ketones.), alcohol. animal and vegetable oils, alkalis and compression set.

- EPDM’s dynamic and mechanical properties are, in general, between natural rubber and SBR.

Limitations

- Poor resistance to petroleum oils, fluids, or solvents because significant swelling would result.

- Poor resistance to aromatic hydrocarbons (e.g., benzol, toloul) and aliphatic hydrocarbons (e.g., kerosene, turpentine).

EPDM White FDA 60° Shore A

There are two basic types of EP rubber available in today’s market—EP and EPDM. EP is a copolymer of ethylene and propylene, while EPDM is a terpolymer combining ethylene, propylene and a diene monomer. EP uses a peroxide cure system. EPDM uses a sulphur cure system.

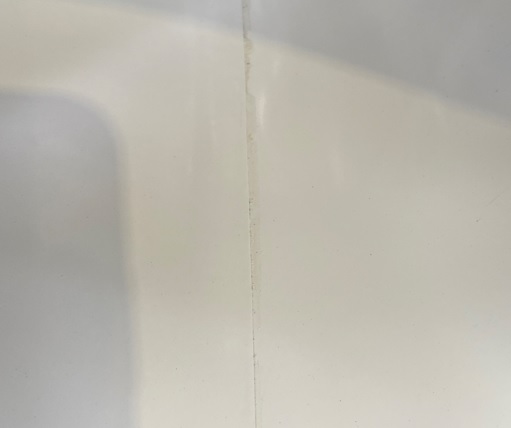

Filcoflex B.V.’s EPDM is an EPDM white FDA 60° Shore A is a rubber material sheet from rolls. EPDM is used for a number of purposes, to cut custom gaskets and to make flexible sleeves among other things.

The sheet is a roll material, the roll are 1200mm wide and have 10 meter length.

EPDM has a good solvent, acid and alkali resistance, and a good general chemical resistance. EPDM has a higher temperature resistance than most plastics (e.g. Poly Urethane) or natural rubbers.

General properties

| Name | EPDM White FDA |

|---|---|

| Description code | EPDMw1 / EPDMw2 / EPDMw3 / EPDMw5 |

| Material | Ethylene Propylene Diene Monomer rubber |

| Color | White |

| Hardness | 60 ° Shore A (+/- 5° Shore tolerance) |

| Tear Resistance |

25 N/mm DIN 53507 |

| Tensile Strength | 11,0 MPa ASTM D412 C |

| Specific Weight |

1,16 g/cm3 |

| Maximum Elongation | 550% DIN 53504 |

| Post Curing of sheet material |

Sulfur cured |

| Operating Temperature | -25 °C to 100 °C -13 °F to 212 °F |

| Air Permeability | 0 |

| Type of Material | Sheet on roll, 1200mm (+/- 20mm) x 10000mm |

Pressure Resistance for Flexible Connectors

0,34 Bar / 5.0 PSI For temperatures up to 90 °C / 195°F. Please see “Operating Pressure Guide” for further information. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

Weighing Applications

High volume weight and capacity weighing and dosing applications please see “weighing and dosing guide” for further information.

Chemical Resistance

- Good temperature resistance

- Good ozone resistance

- Very good acid resistance

- Very good alkali resistance

- Good CIP resistance

- Good weather resistance

- Poor oil resistance

- Poor petrol resistance

Food Contact Compliancy

Filcoflex B.V. hereby declares that below mentioned list (1) of EPDM rubbers comply with the following regulations (2) for repetitive contact with food and foodstuffs.

EPDM rubbers (1)

- EPDM White FDA 1mm

- EPDM White FDA 2mm

- EPDM White FDA 3mm

- EPDM White FDA 5mm

- EPDM White FDA 6mm

List of regulations to which the product complies (2)

- FDA 21 CFR of the United States of America

- 2600

- European Union

- (EC) 1935/2004

- (EC) 2023-2006

Free of substances

None of the following chemicals is intentionally added to EPDM White FDA, and are therefore suspected to not be present in the material.

- Phthalates

- DEHP

Production Methods used

Joining / Bonding:

All seams are overlapped seams, the ends are made thinner before they are overlapped. The overlap seam has a thickness within that has a +1mm -0.5mm tolerance compared to the original material thickness.

*seams are grinded before they are glued for a better adhesion.

Cutting:

- Stainless Steel knives

- Water Jet

Availability for shapes, couplings and product features

EPDM White FDA can be custom made in to flexible sleeves and number other products.

This document summarizes all the different shapes, end couplings and product features that are available for this flexible material.

Please find detailed explanations on the information pages about these subjects:

- product features & options

- shapes & forms

- coupling ends

Related Filcoflex Product Shapes & Forms

Rectangular – Rectangular

000 / 001 / 002 / 003 / 004

Rectangular – Round

051 / 052 / 053 / 054

Round – Round

550 / 551 / 552 / 553 / 554

Oval – Oval

660 / 661 / 662 / 663 / 664

Round – Oval

651 / 652 / 653 / 654

Related Filcoflex Product Coupling Ends

Jacob Flexible Connections

Flexible Connectors

Hoses

- Rubber Hose On Roll (HOR)

Up to 2000mm long

Seals, Gaskets and Covers

- Cut sheets and patterns

- Gasket cut from sheet

Related Filcoflex Product Options

Integrated Reinforcement rings

To withstand vacuum collapse or over pressure expansion.

- Stainless Steel, 3mm / 5mm / 8mm (VR)

- PE 6x10mm poly ethylene (VRPE)

- Stainless Steel T bar 20x25x3 (VRT)

Padding on Flange or Cuff

Label

- NFC chip encased in Poly Urethane pocket

Stitched on to the end of the EPDM product - Printed label encased in Poly Urethane pocket.

3 optional colors (yellow/blue/white)

Stitched on to the end of the EPDM product - RFID chip encased in Poly Urethane pocket

Stitched on to the end of the EPDM product