- Products

- Technical

- Customize

- Material

- About

- Contact

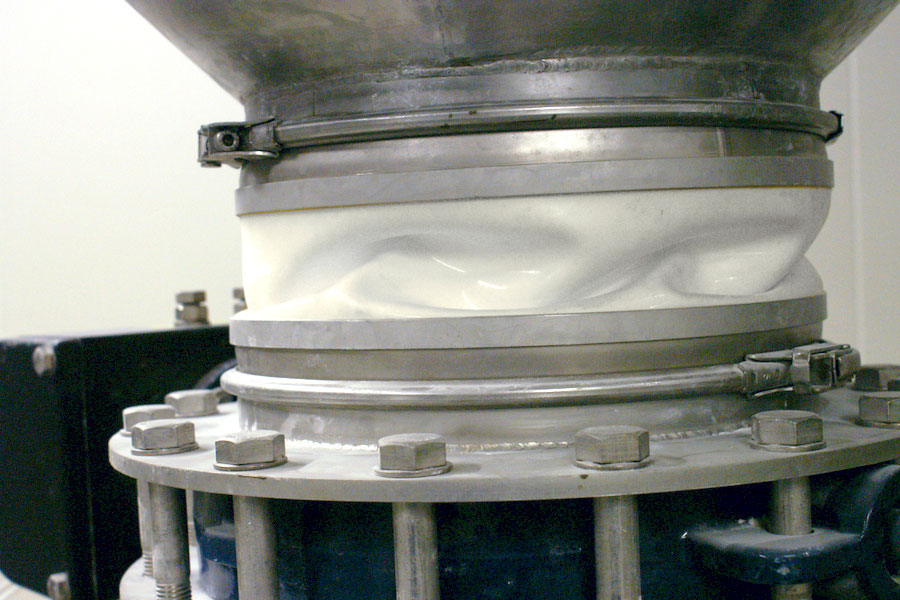

“Filcoflex is supplier of PU sleeves that are applied as flexible connectors to the transport channels in the world of solids. Since it is not possible to certify these products conform ATEX 95, the company had tests performed by Inburex. The accompanying report shows that the sleeves are safe to utilize in explosion hazardous spaces.”

When an ATEX certificate for sleeves is not feasible…

…but the evidence of explosion safety certainly is required.

As most companies know, the ATEX guideline consists of two parts: in short; the former ATEX 95 replaced by ATEX 114 covers appliances that are. utilized in explosion hazardous environments, while the former ATEX 137 replaced by ATEX 153 is set up to create a safe work environment for employees (Health and Safety -ATEX). According to ATEX 114 all electric appliances, and in addition mechanic, pneumatic and explosion surpression or extinguisher systems, have to be certified. In some cases this requires a Notified Body. Based on this certificate the end user knows within which zones these systems or appliances are safe to utilize.

Appliances are covered by ATEX 114 when they are being used in an explosion hazardous environment and when they contain a possible source of ignition (such as a battery or power connection) ór has been developed to transfer energy. The last would be the case with for example a gearbox, a v-belt or even a pump. When we look at PU sleeves or ‘flexibles’, we are dealing with products that are manufactured to create a flexible connection for pipe lines or appliances that create certain motions (e.g.:sieving /vibrating). When solids are being transported through these pipes, chances are several elements will statically charge in which case a discharge could cause an explosion. In that case there are two possibilities: there is an actual explosion and the pressure is slowly relieved (e.g. by venting) ór the explosion is detected in an early stage and suppressed using a fire extinguishing system. In both cases pressure will increase in the pipes (and the sleeves) and it is crucial the sleeve will not tear.

Despite the fact that there is still the risk of ignition during the transport of solids through the sleeves, Filcoflex encountered the problem that sleeves are not certifiable according to ATEX 114. After all, they don’t contain a potential source of ignition and are not developed to convert energy. However, because the company values the importance of setting guidelines to create safe conditions and use of their products, in 2010 Inburex and the Wilhelm Jost Institut testlab were consulted.

Inburex (see also boxed text)has performed two types of tests on the sleeves. First of all they tested what the explosion resistance is for a powder (dust) explosion in a pipe. In other words: how high can pressure increase before the sleeves possibly tear and what are the consequences when this actually happens. Werner van Loon, who works at Filcoflex: “We aimed to score at least 1 – 1,5 bar explosion pressure resistance because the explosion valves–release plates or valves that slowly vent out pressure in the event of an explosion – usually open at an overpressure of 0,7 bar.

The sleeves must resist more than 0,7 bar so the valves can relieve pressure at a safe location in the explosion. If they are not strong enough and for example the sleeves would tear at a pressure of 0,5 bar, the explosion will be vented out in a completely uncontrolled manner ánd at the wrong location.” The tests showed that the explosion pressure resistance of a Filcoflex Flexible Connector for a real explosion was more than enough; in some tests the pressure that caused the sleeves to tear exceeded 2 bar.

The second test regarded the electrostatic properties. ‘Anti static’ sleeves are often inquired about in the solids world. These are sleeves that cannot ‘charge’ as a result of the material that flows along that causes discharges (and therefor powder explosions) as a result of static electricity impossible. Van Loon: “It was important to find out to what degree the two Filcoflex PU varieties –that are also used in the aforementioned test – could charge under operational circumstances. We were curious to find out because these Filcoflex sleeves have been applied for many years and never before have been indicated as the cause of an explosion.”

This experience has been confirmed in the tests. Results showed PU sleeves up to certain measurements cannot charge enough to cause an explosion of powders with an ignition energy higher than 1 mJ. In reality this proves to cover almost 99,9% of all powders. Only materials such as sulphur– a substance that has an extremely low ignition energy – could ignite following the discharge of these sleeves.

Finally tests performed by TNO Triskelion have established that the PU sleeves meet the FDA and EU food contact safety requirements and have been certified. This is particularly important for the application of products in the nutrition industry. The different criteria and test results are documented in a ‘Message’ and form an important source of information for the end user when aspiring to create a safe production environment.

Sleeves or flexibles are a typical example of a product group that cannot receive ATEX certification. The same applies to hoses, rigid pipes, hand operated shut-off valves, ladders and big bags. Gerard van Laar, who works as a consultant for Inburex: “That however, does not mean the user or supplier should not pay close attention; but should maintain to use common sense. For example: use high quality components and materials and ensure that the required earthings are in order. When it comes to the quality of the components the user can only rely on the information that has been provided by the supplier. Filcoflex has definetely made the right move here: have an independent institution test the properties of their products and document the results in a report.”

Van Laar reports there is still a large demand for safe installations. Not in the least because dust explosions still occur regularly (Like the dairy industry that handles with milk powders) and in most cases the cause proves to be static electricity. This may occur when unsuitable hoses or sleeves are applied that do not have sufficient Electro static conductivity. Mr Van Laar: “Fortunately I noticed in practice, that problems involving static electricity and the possible consequences receive more and more attention and that is off course a step in the right direction.”