- Products

- Technical

- Customize

- Material

- About

- Contact

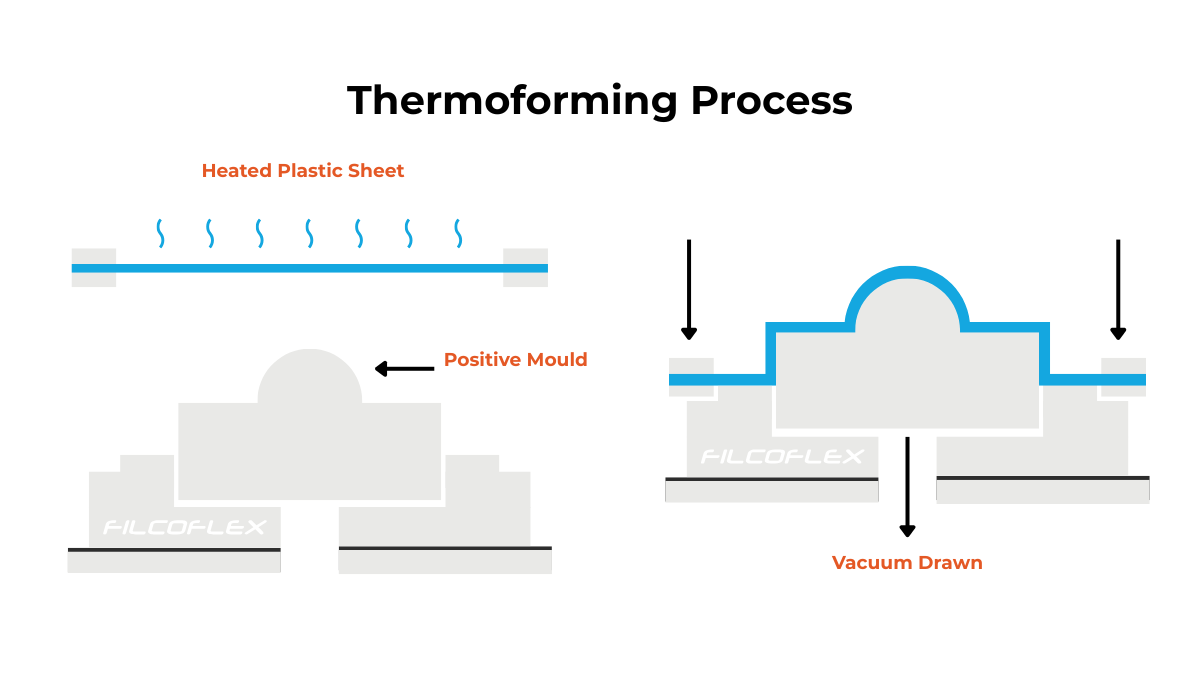

Filcoflex silicone weighing bellows are created through a manufacturing technique called compression molding. A predetermined amount of silicone material is placed on a mold and vertically compressed by a hydraulic press. This method makes sure that the silicone fills the mold evenly, producing bellows that fit perfectly into your system.

The translucent silicone material is made from compression-molded silicone rubber (an elastomer of silicon, carbon, hydrogen, and oxygen). More carbon is then incorporated into the base silicone to achieve the electrostatic dissipative properties of the antistatic black version.

We have a traceability program that archives production run samples for up to 7 years after the production date so they can be retested and re-evaluated upon request.