- Products

- Technical

- Customize

- Material

- About

- Contact

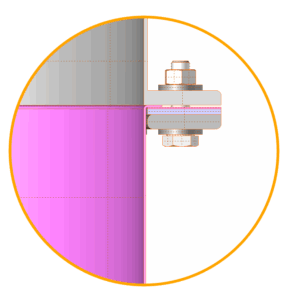

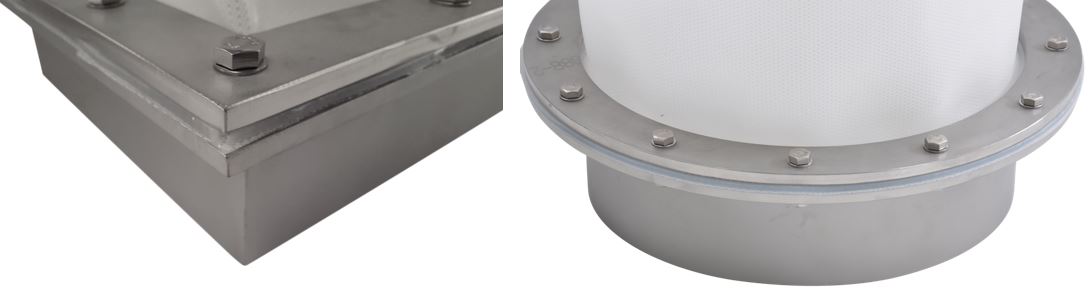

Because the entire flange connection is airtight and leak free there can be no contamination between the flanges, making the connections suitable for Clean In Place. Mounting all the nuts and bolts requires more time compared to any quick connect type of flexible connection. However, the secure seal provided by this connection removes the need for disassembly when cleaning.

Flange Fitted Flexible Connections are ideal products for operations with CIP design and process. When the right flange design is used, this connection has a smooth flow profile and integrates well to any system.

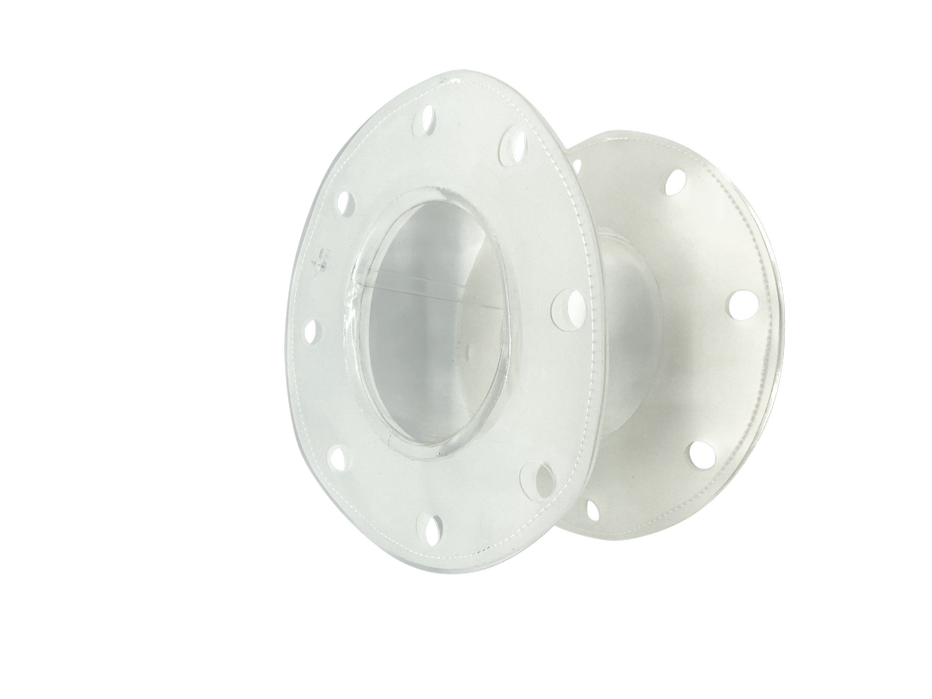

Thermoforming & High Frequency Welding

Depending on the shape and structure of a customized product, we use two methods to produce a Flange Fitted Flexible Connector.

Thermoforming heats the material until pliable. Then, the heated sheet will be placed into a three-dimensional mold of the desired shape. Once cooled down, excess plastic is trimmed down. High Frequency Welding, on the other hand, uses electromagnetic waves to generate heat within the material itself up to the point of fusion where their molecules can bond together. This results in a strong and flawless seam that is as strong as the original unbonded material.

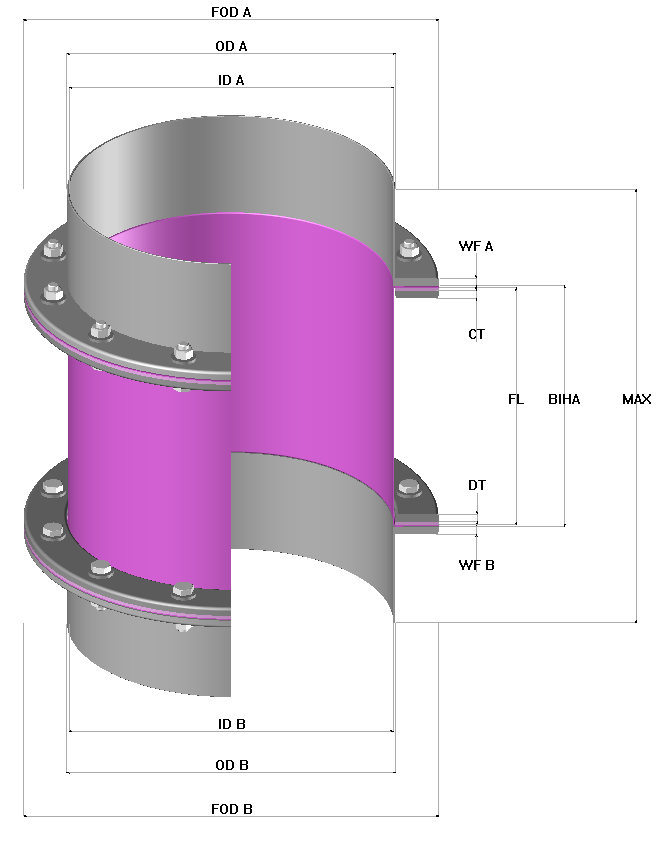

| PARAMETER | EXPLANATION |

|---|---|

| F OD A | Flange Outside Diameter |

| OD A | Tube Outside Diameters |

| ID A | Inside Diameter |

| WF A | Welding Flange Thickness |

| CT | Counter Flange Thickness |

| FL | Length Flexible Sleeve |

| CL | Length Flexible Connector |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| DT | Counter Flange Thickness |

| WF B | Welding Flange Thickness |

| ID B | Inside Diameter |

| OD B | Tube Outside Diameter |

| F OD B | Flange Outside Diameter |