- Products

- Technical

- Customize

- Material

- About

- Contact

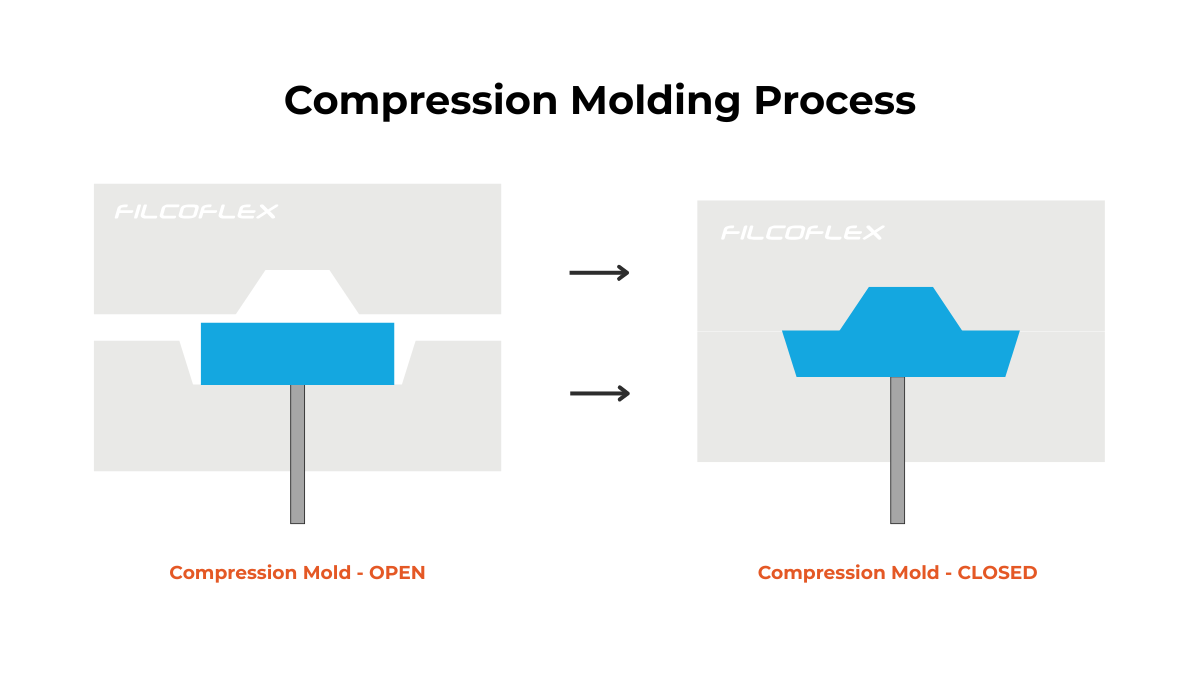

Compression Molding

Filcoflex silicone weighing bellows are created through a manufacturing technique called compression molding. A predetermined amount of silicone material is placed on a mold and vertically compressed by a hydraulic press. This method makes sure that the silicone fills the mold evenly, producing bellows that fit perfectly into your system.

The translucent silicone material is made from compression-molded silicone rubber (an elastomer of silicon, carbon, hydrogen, and oxygen). More carbon is then incorporated into the base silicone to achieve the electrostatic dissipative properties of the antistatic black version.

We have a traceability program that archives production run samples for up to 7 years after the production date so they can be retested and re-evaluated upon request.

This is possible but only in systems with minimal deviation. Please consult us if you are unsure.

Yes, we can customize silicone weighing bellows with your own specifications at a minimum number of pieces. Our standard diameters for our 3 variations (Translucent White, Asymmetrical Conical White, Black) are also able to accommodate a certain stretch threshold.

There will be a longer lead time because we have to create new molds. We estimate 14 to 20 weeks for designing and producing, but this can extend to 6-8 weeks more if modifications are necessary after the first test samples.

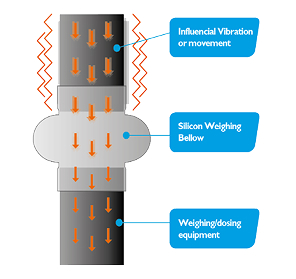

Silicone bellows are used as a decoupling compensator to minimize force transfer from moving equipment to sensitive weighing equipment.

For best performance and employee safety, we recommend using couplings with our bellows. Basic couplings include hose clamps KLB09 and KLB20. For a more secure fit, you can opt for a Jacob FDM or Tri-Clamp silicone bellows version.