All poly urethane weighing bellow designs are available in a number of flexible materials. These materials can be combined together to form a 2 or 3 part fused weighing bellow. We offer transparent, blue metal detectable, white and antistatic poly urethane materials.

Food Contact Compliancy

All TPU films are food contact compliant according to international food contact regulations. PU-UF03, PU-UF07, PU-UF1, PU-UF15 and PU-UF3 have been migration tested for specific food contact compliancy, and comply with following regulations. Some other may only be available with a food contact compliancy declaration.

Operating Conditions

Pressure resistance depends on the thickness of the polyurethane film. More information can be found on the individual pages of each material datasheet. We also offer pressure testing for your custom weighing bellow. For applications with specific pressure resistance requirements, we will be happy to make recommendations.

Temperature Resistance

All Filcoflex polyurethane materials can withstand a constant temperature up to 90°C / 194°F. Please refer to individual material pages for more detailed information.

ATEX & Explosion Safety

Filcoflex conducted independent testing to determine ATEX compliance and electrostatic properties of polyurethane materials. Please refer to individual products and materials pages for detailed information.

All TPU films are food contact compliant according to international food contact regulations. PU-UF03, PU-UF07, PU-UF1, PU-UF15 and PU-UF3 have been migration tested for specific food contact compliancy, and comply with following regulations. Some other may only be available with a food contact compliancy declaration.

United States Food contact safety regulations FDA 21 CFR

- 175.105

- 177.1680

- 177.2600

European Food Contact safety regulations

- (EC) 1935/2004

- (EC) 10/2011

- (EC) 2023/2006

Chinese Food Contact regulations

- GB 4806.7 – 2016

- GB 5009.156

- GB 31604.1 – 2015

- GB 4806.6 – 2016

- GB 9685 – 2016

Thermoforming

PU BG is made by thermoforming 2 or 3 parts from a poly urethane sheet material. Thermoforming the poly urethane sheet material results in a shaped part that does not have any height seam.

High Frequency Welding

All parts are welded together with high frequency (HF) welding equipment. Our latest HF welding equipment allows for seamless welds, creating a part comparable to a casted or molded part. All polyurethane (PU) flexible materials indicated for this product can be combined together to form the weighing bellow end product. Combinations between different thicknesses can be made. When thermoforming a PU sheet, the original thickness is reduced. This thickness reduction allows for an even more flexible bellow.

With the classic bellows shape, the standard practice is to use the same thickness for the top and bottom sections to maintain flexibility. However, it is possible to use a thicker material or materials with different thicknesses.

Polyurethane weighing bellows is one of the most customizable flexible connectors. It can be designed with the following coupling ends:

Flexible Connectors

- Hoseclamp Fitted

- Bolt Pattern Flange Fitted

Harmonica sleeves

JACOB Flexible Connections

Tri-Clamp Flexible Connections

Depending on your system requirements, more options can be added to your PU BG CFT.

Extended polyurethane weighing bellows

For pipes with great gaps or distance, silicone weighing bellows can be extended using the same material as the bellows.

1 or 2 sides extension

Integrated Reinforcement Rings

To withstand vacuum collapse or over pressure expansion.

Stainless Steel, 3mm / 5mm / 8mm (VR) PE 6x10mm poly ethylene (VRPE)

Earthing or Grounding

Earthing or grounding provides a path for fault currents to safely flow to the earth. This feature prevents potential hazards such as electrocution and equipment damage, thus promoting a safer workplace.

- Earth connection on integrated Flanges with M6 Stud or Nut (A)

Earth connection on integrated rings with M6 Stud or Nut (VRA)

Sleeve within a sleeve

Inside Cone / Inside Sleeve (7) for applications in explosive environments

Padding on flange or cuff

- Stitched on gasket on bolt pattern flanges (VF)

Stitched on gasket on end cuffs (VF)

Label

- NFC chip encased in Poly Urethane pocket Printed label encased in Poly Urethane pocket

- Can contain customized Text, Bar code, QR code 3 optional colors (yellow/blue/white)

RFID chip encased in Poly Urethane pocket

Pneumatic or Compressed Air Hoses

TPU compressed air hoses 8×5,5mm welded in.

Embossing

Embossed logo or marking welded in thermoplastic material

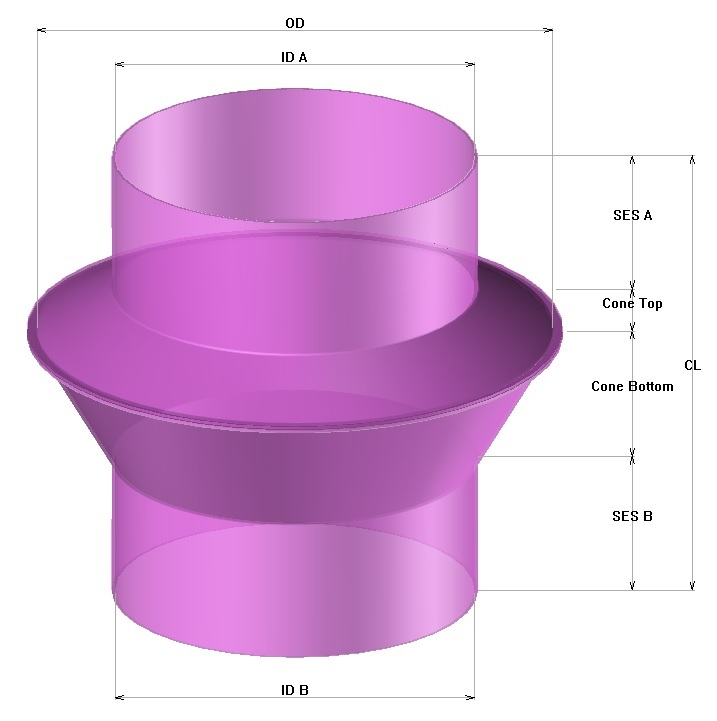

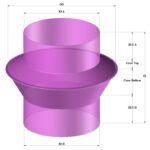

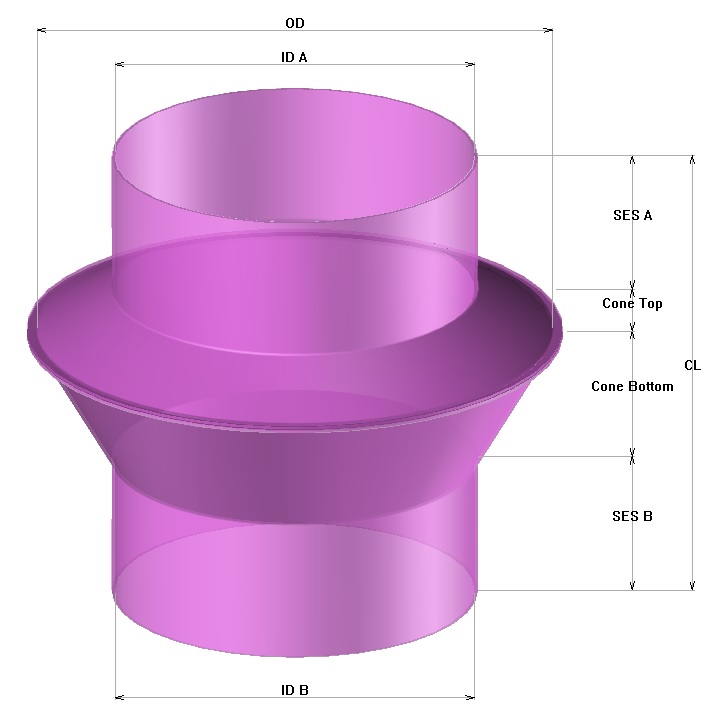

Two parts are thermoformed and welded together to form an asymmetrical conical bellows shape with a 60° angle. Top and bottom part can be made from different polyurethane materials. The top cone and cuff are made in 0.7 mm polyurethane (standard), 0.3 mm, 1.0 mm & 1.5 mm polyurethane are optional. The bottom cone and cuff are made in 1.0 mm polyurethane (standard), 0.7 & 1.5 mm polyurethane are optional. The standard thicknesses are followed to provide a more flexible top cone than bottom cone. However, combinations such as a 0.7 mm top and 1.5 mm bottom are also possible.

The thinner top cone provides the required flexibility while the bottom cone retains the shape to prevent powder pile-up inside the bellow. For applications requiring more flexibility, PU BG CFT can be the better option.

PU BG AC can be further customized by extending the cuffs on both sides to achieve a longer total length. This can be easily cut to length in production or with a pair of scissors. Different thicknesses and colors are optional.

Are you curious about the product?