- Products

- Technical

- Customize

- Material

- About

- Contact

Filcoflex is a family-owned company dedicated to manufactering flexible solutions that improve production hygiene, promote workplace safety, and reduce factory downtime.

Years of knowledge and experience

Distributors and resellers worldwide

Unique article numbers of customized products

Filcoflex products manufactured

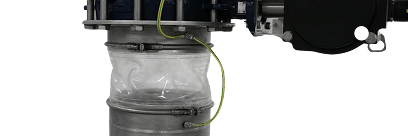

Our flexible connectors are used to produce a wide range of products, from daily items like coffee, sugar, or dairy to high-grade goods like pharmaceuticals, minerals, and plastics. Filcoflex mainly operates in the dry substances sector, offering products for bulk powder transport and handling. Our clientele belongs to four main industries.

Hygiene is the top priority in the food industry. Manufacturers must be sure that components are free of contaminations that can put their consumers at risk and cause costly recalls.

As a highly regulated industry, pharmaceutical manufacturers must follow strict guidelines. Parts and components should be suitable for use in clean room setting.

Harsh chemicals put workers and your factory at risk. These materials release fumes that can cause health hazards, are flammable, and explosive.

The two main concerns when handling minerals are abrasion and risk of blow outs. Valuable ores and powders must be processed sustainably and efficiently.

This unique offering allows us to create connectors in a variety of sized and materials. We manufacture based on your needs and rquirements, creating tailored solutions that work for you.

During emergencies, we can arrange same day manufacturing for you. We know that prolonged downtime harms your factory's profits and productivity.

We cooperate with experts and institutes to have our materials and products inspected. Be it vacuum, food safety, or hygiene, we can stand behind our products with confidence.

At the core of our business is our commitment to innovation and streamlined operations. We created our brand with you, the customer, in mind.

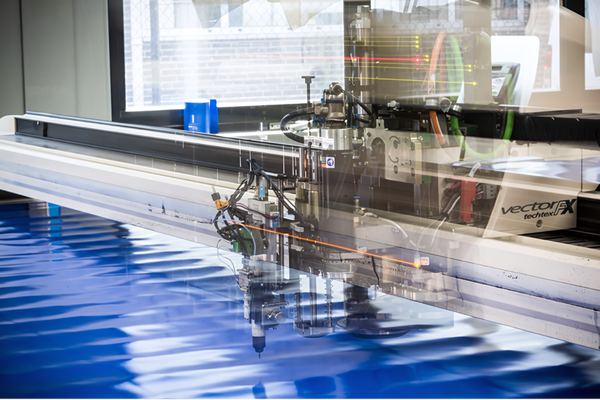

Equipped with 50 years of knowlegde, we know the best way to manufacture flexible connectors. Our trained production workers use the latest technology to create strong and long-lasting products.

Filcoflex specializes in design

and manufacture of polyurethane,

silicone, rubber, and textile flexible

connections for bulk product

transport.