- Products

- Technical

- Customize

- Material

- About

- Contact

Pneumatic Bulk Bag Seal – Quick Detach (PBS-QD) by Filcoflex is a smart solution for safely and efficiently connecting bulk bags to filling or discharging systems.

Designed for fast and secure operation, the inflatable seal expands to hold the bag firmly in place, preventing dust and product leakage. Its quick detach design allows for easy bag changes that reduces downtime and improves productivity. Made from polyurethane material with a smooth and non-porous surface, PBS-QD can be applied in industries like food and pharmaceutical where hygiene and product purity are major factors. This seal is compatible with different bag sizes and types. The end connection can be made from standard Filcoflex products or a customized solution depending on your needs and application.

Filling and emptying bulk containers

PBS-QD can be used to fill or empty all kinds of bulk containers such as: big bags, plastic bag, paper bag, super sack, flexible intermediate bulk containers (FIBCs), drums, bags and bins with or without liners, bulk packaging, bins, and vessels

Customization and hygiene

PBS-QD can be made to any custom diameter or length with a short delivery time. Polyurethane is a more hygienic material because it does not deteriorate, crack and does not turn brittle. The surface of polyurethane on both sides is glossy and non-porous, making it easy to clean. Polyurethane is tested safe to use for repetitive contact with foods with the most common international food contact regulations.

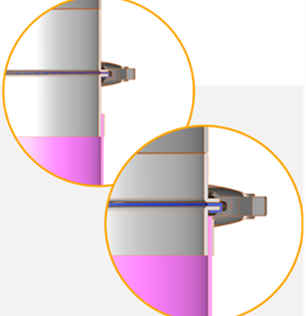

PBS-OT is built with welded in compressed air lines, made of poly urethane hoses. The hoses are completely airtight welded in to the upper rim of the polyrethane inflatable bladder. The 8×5.5mm PU air hose is suitable to use with any standard 8mm push in air fitting, allowing it to attached and detach within seconds. The hoses are welded up straight to stay clear from the bulk bag. The inflatable bladder is 100% free of any obstructions, sharp edges or pneumatic fittings. The full bladder length can be used to clamp the bulk bag or container. Because there are no obstructions or fitting in the inflatable bladder, more bladder surface can be used making it easier to position or align Bulk bags or containers without losing time.

The 3D HF welding technique used to weld the hoses in the Inflatable clamp ensures a 100% seal. Each weld is tested before the Pneumatic Bulk Bag Seal is shipped out.

Threaded fittings create possible entry points in to the bladder. This can be classified as a hygiene risk. By welding the hoses in the upper rim instead of using threaded fittings in the outside sleeve, the entire inflatable bladder surface is free of any sharp object.

Threaded parts can loosen and because of this parts can be lost in the machinery or bulk container or bag. Threaded fittings can start to leak, and can’t be tied down because the inside is not accessible to hold while tightening down.

PBS-OT as a standard comes with 2 hoses, divided over 180° from each other. The quantity of hoses can be anywhere between 1 and 6 pcs. The number of hoses has an effect on the speed of inflating and deflating. The distance between the hoses can be evenly spaced around the full 360° circumference. The hoses can also be orientated together on one side.

The polyurethane air hoses can be easily cut to length. The standard length is 175mm. Simply use a pair of Multipurpose Miter Shears for the best and easiest cut.

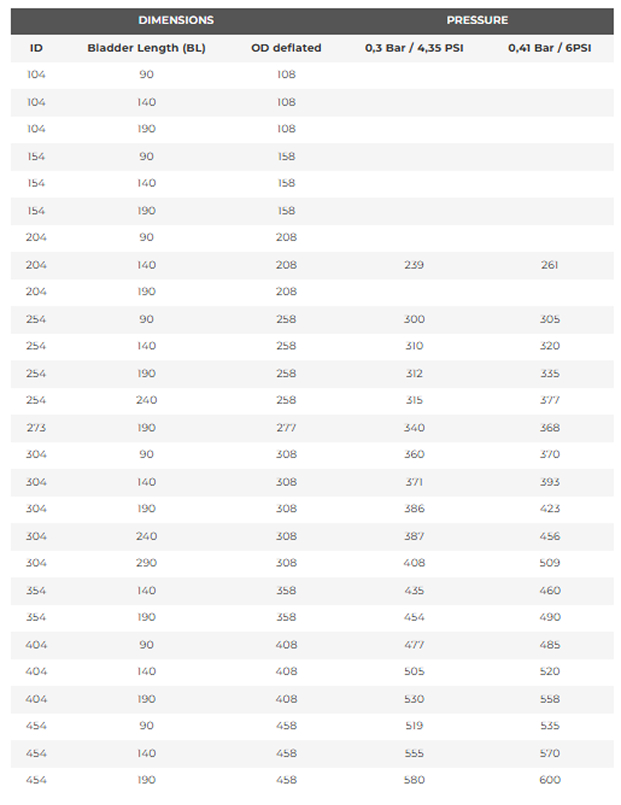

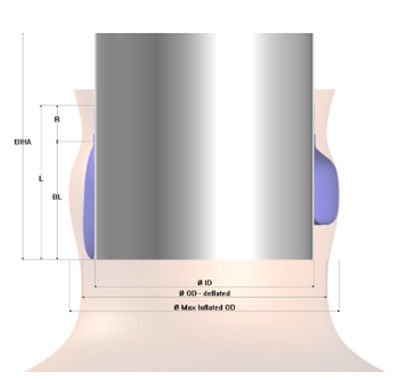

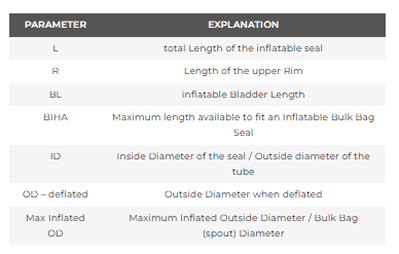

The list of sizes will keep expanding with every new size that is manufactured. If your required size is not listed yet, please send us the requirement and we will be happy to test it for you Every pneumatic bulk bag seal is custom made to the required filling head / chute diameter and length, calculated to be right size for each diameter Bulk Bag that is used in your filling process. All custom made products have a short delivery time.

There are no pinch points no sharp edges or metal objects in the clamping area that endanger the hands or fingers of operators. Safety instructions can be embossed in the PU material.

The ideal compressed air line operating pressure is recommended to 0,3 Bar / 4.3 PSI. If a higher pressure is required to reach a larger inflated diameter. Please first contact Filcoflex for advise. The absolute recommended maximum pressure is 0.41 Bar / 6 PSI but this does not apply to larger diameters or lengths If air pressure recommendations are exceeded this may cause permanent damage to the inflatable bladder. Even though a higher pressure can be held in without any immediate burst, it is recommended to not to exceed the maximum pressure recommendations.

A hand operated button or switch as well as a food pedal can be used to operate the inflation of the seal. Filcoflex offers a full kit with a hand button.