- Products

- Technical

- Customize

- Material

- About

- Contact

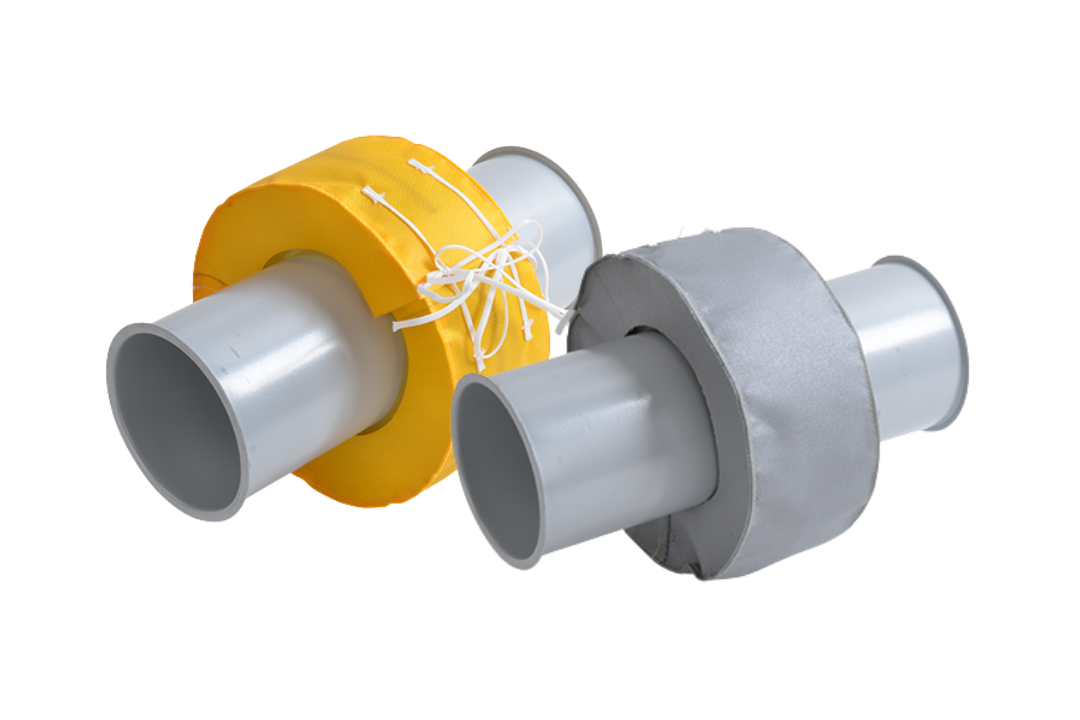

Spray Shields are applicable in pipes transporting liquids. When pipes, pipelines and valves are used to transport gases and liquids, gaskets are used to seal flange connections. In certain situations, a leak may occur and spray out material that may be toxic or dangerous. Spray shields can be the solution to improve health & safety in industries where chemical solvents are being processed and where extreme temperatures occur in the installation. Spray shields help in faster leak detection by using an indicative material that cover the flanges. They are used in chemical plants, oil refineries, paper mills, food processing plants, steel mills, pharmaceutical plants and power generating plants worldwide.

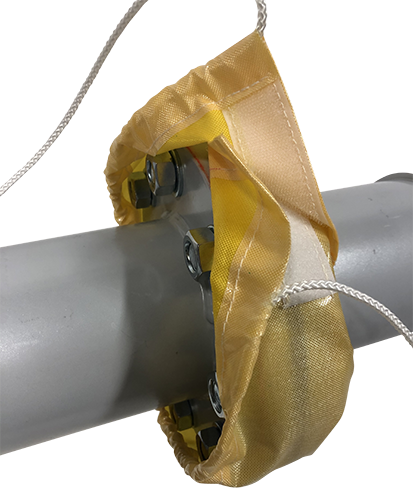

Chemically resistant and indicative

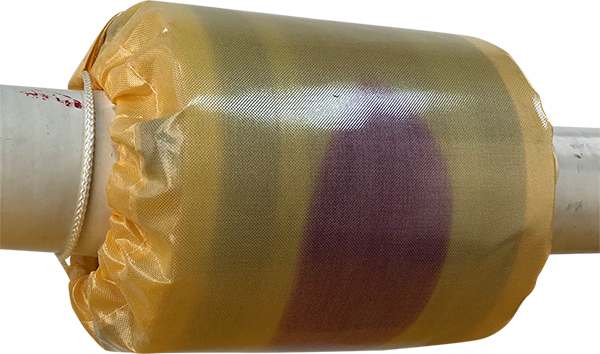

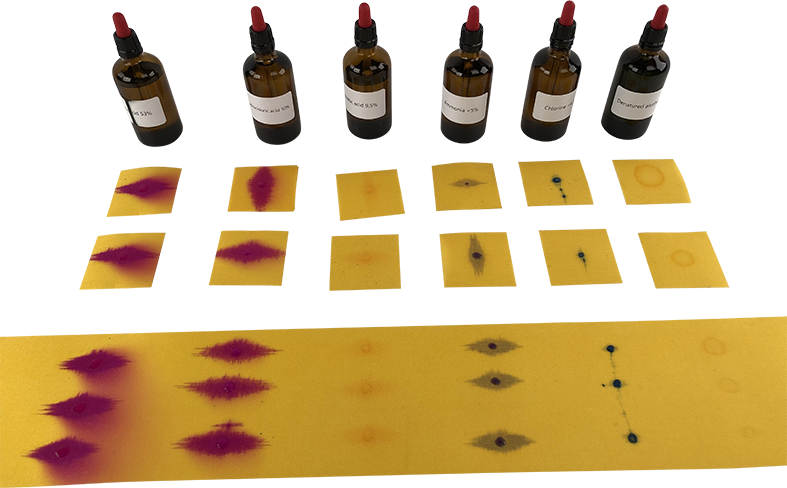

Sprayshield can be made in a plain yellow color which changes to purple when in contact with chemicals. The entire Sprayshield is a color indicator which ensures that the leak always hits the color indicative material (this is not the case when only a PH strip is used at 1 point).

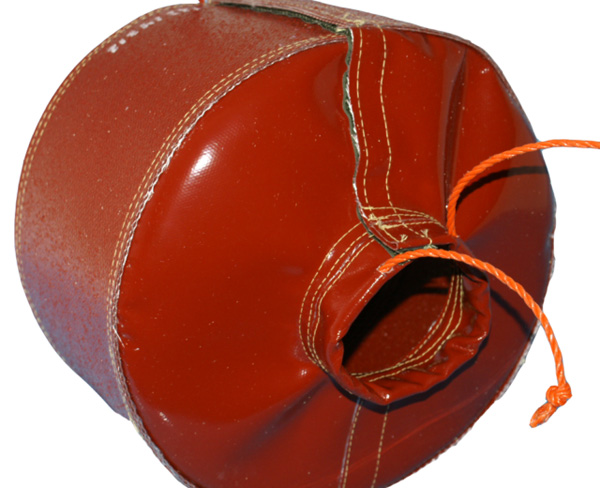

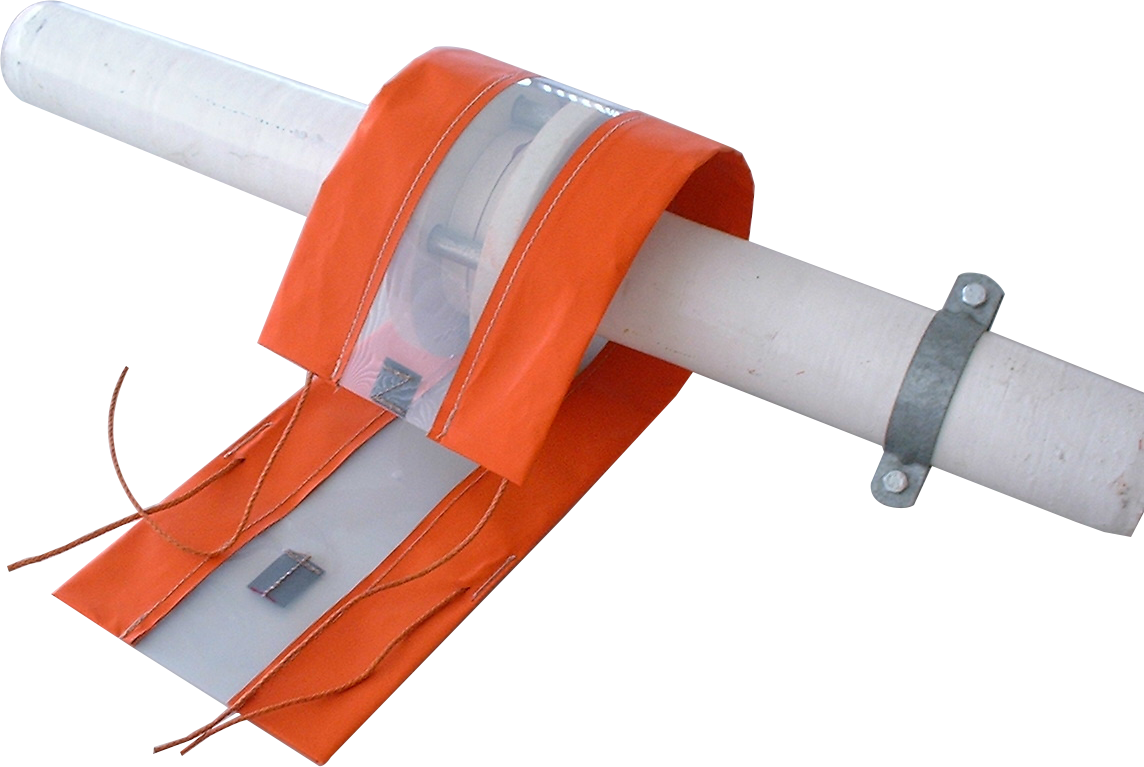

High and low temperature resistant

Sprayshield can be made in glass fabrics with silicone coating for a high temperature resistance. High chemical and temperature resistance Sprayshields made in 100% PTFE films, in translucent or other colors have the highest chemical reistance and temperature resistance.

Employee and operation safety

By using a material that reacts with chemical solvents, these indicative spray shields act as indicators of leakage occurring in flange connections. This way even the smallest leakage can be detected at an early stage, preventing damage to persons and equipment. The discoloration is visible from the outside, allowing detection without the need for the shields to be opened. As an added benefit the spray shields also prevent a spray out of any leak to its surroundings. The indicative material has a very high chemical resistance and is available in an orange colour that becomes translucent or white when coming into contact with all sorts of chemicals, acids and alkaline solutions. High & low temperature In addition to the indicative flange protector for liquids, there are also extremes of high and low temperatures. These designs are not indicative. These heat- or cold-resistant spray shields prevent damage to your installations or equipment. Also, these covers help protect personnel and the environment from the disastrous consequences that can cause a leak.