- Products

- Technical

- Customize

- Material

- About

- Contact

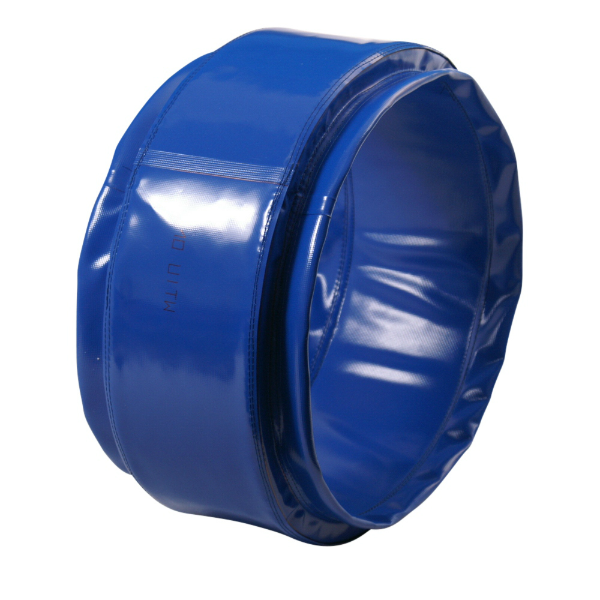

These connectors are uncomplicated by nature. The flexible material is paired with an adjustable hose clamps for security. The connectors can be designed in various shapes, including round, oval, or square and in any diameter, circumference, height, and length. For longer lengths, reinforcement rings are added to prevent the connector from being sucked inwards.

Thermoforming & High Frequency Welding

Depending on the shape and structure of a customized product, we use two methods to produce a Hose Clamp Fitted Flexible Connector.

Thermoforming heats the material until pliable. Then, the heated sheet will be placed into a three-dimensional mold of the desired shape. Once cooled down, excess plastic is trimmed down. High Frequency Welding, on the other hand, uses electromagnetic waves to generate heat within the material itself up to the point of fusion where their molecules can bond together. This results in a strong and flawless seam that is as strong as the original unbonded material.

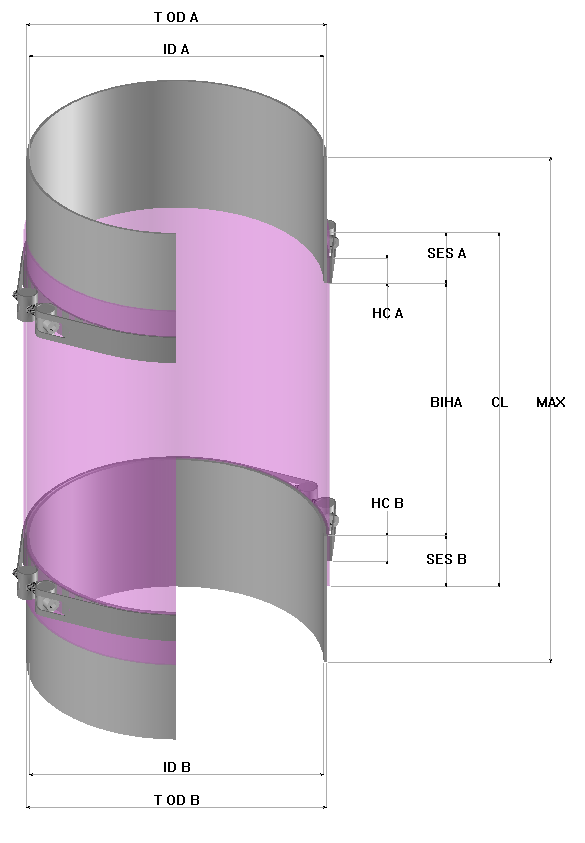

| PARAMETER | EXPLANATION |

|---|---|

| T OD A | Tube Outside Diameter |

| ID A | Inside Diameter |

| HC A | HoseClamp width |

| SES A | Straight End Sleeve Length |

| CL | Length Sleeve total |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| SES B | Straight End Sleeve Length |

| HC B | HoseClamp width |

| ID B | Inside Diameter |

| T OD B | Tube Outside Diameter |