- Products

- Technical

- Customize

- Material

- About

- Contact

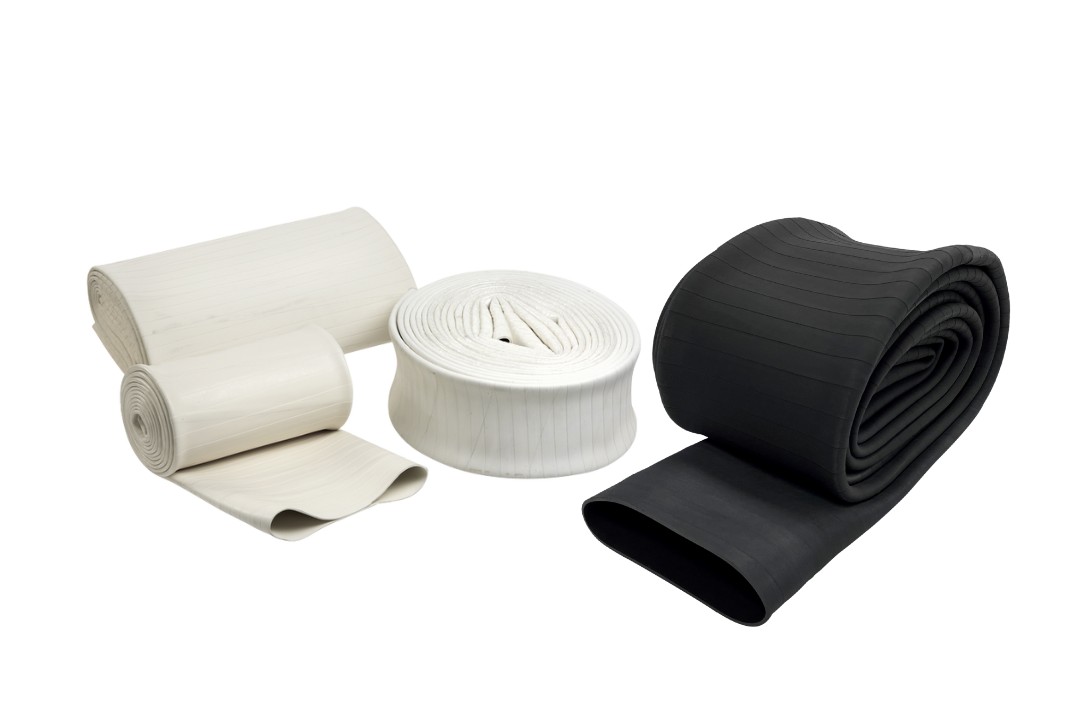

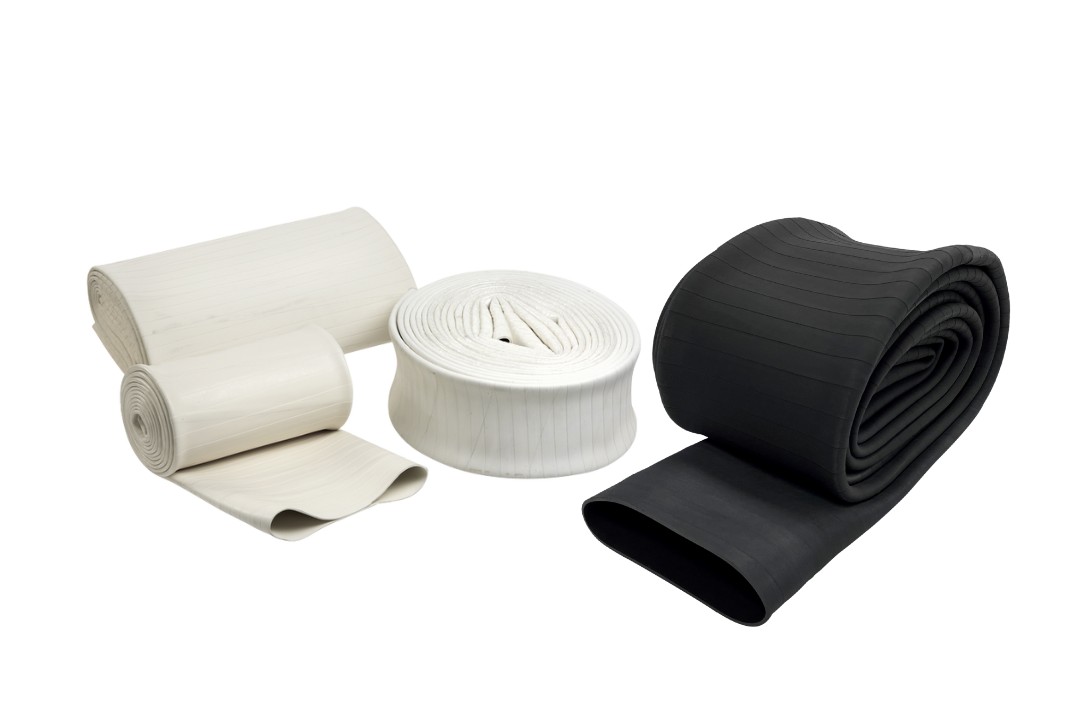

Seamless hoses in rubber have a smooth interior surface and a wrapped and light textured outside finish. Seamless hose is made by wrapping a strip of uncured rubber around a mandrel to form a rubber hose. Before the seamless hose is cured inside an autoclave, the rubber hose is wrapped with a textile band to wrap the rubber tightly around the mandrel. When the seamless rubber hose is cured it forms a smooth inside and wrapped outside surface. Seamless rubber industrial hose can be used on round, rectangular or oval ducting if the standard diameters match the duct circumference. Available materials include natural gum rubber, EPDM White, EPDM Black Antistatic, White Nitrile FDA, Neoprene Black, and Black FKM Viton.

Food Contact

Due to the inside smooth surface, hose on rolls can be used in food contact applications. Filcoflex HOR are made from FDA compliant materials. For more information, visit our Materials page.

Chemical Resistance

Hose on rolls can be used as an industrial hose or sleeve if certain level of chemical resistance is required

Force Transfer

Seamless hose is a quick and easy way to connect pipes or moving machine parts to form a soft connection. Soft connections and sleeves are required to absorb vibrations, oscillation, axial compression and vibrating movements of powder handling equipment.

Standard Diameters

Seamless Rubber Tubing comes in a great variety of diameters. The rubber has a good stretch capacity and will allow stretch to fit larger tube sizes up to 5 or 10% larger will not damage the rubber hose.

Every production facility often has a great variety of sleeve lengths but mostly use standardised diameters. Seamless Rubber Hose can be put on stock in standardised diameters and can be cut to the required length. This reduces the amount of different sleeve lengths you have on stock, and therefor reduces stock value levels greatly. Simply cut the required length of the seamless hose and stretch it to the right diameter.

Testing and Overshooting

Mechanics and OEM on site engineers benefit during testing and troubleshooting of existing or new to be commissioned machinery. They can easily cut the seamless hose and test these trial sleeves to size for an optimal equipment performance. Once the machine runs perfectly the right size hoses or sleeve can be ordered. These rolls or industrial seamless rubber hose are easily kept in vans, trucks and on site stock rooms. Seamless rubber tubing is ideal to make emergency repairs, simply cut the right length sleeve and place it in your material handling process. Most often these hoses are fitted on tubes using a hoseclamp or screwclip. The hose clamps can be adjusted to any tightness. Due to the softness of the rubber hose the hoseclamp can easily compress the rubber to form a 100% seal.

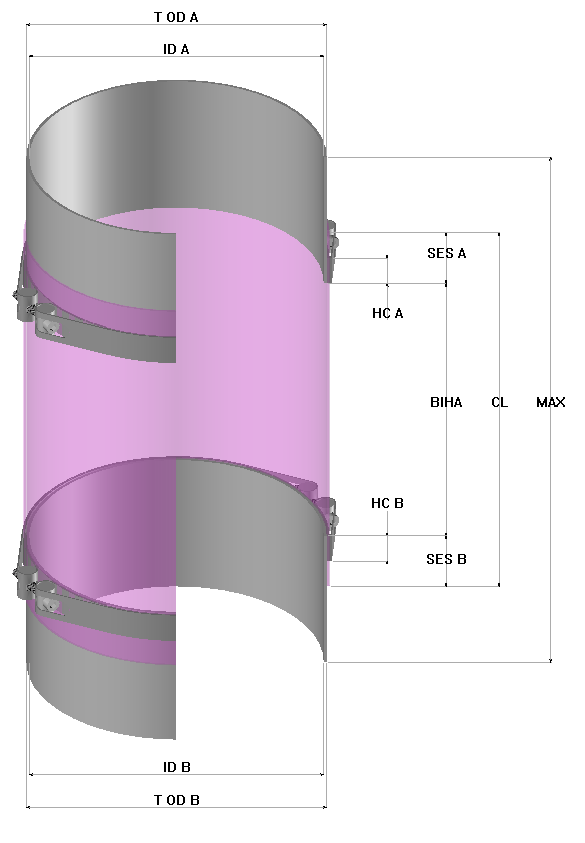

| PARAMETER | EXPLANATION |

|---|---|

| T OD A | Tube Outside Diameter side A |

| ID A | Inside Diameter side A |

| HC A | Hoseclamp width side A |

| SES A | Straight End Sleeve side A |

| CL | Connector Length (total) |

| BIHA | Length between Tubes / Flanges |

| MAX | Maximum available build in height |

| SES B | Straight End Sleeve side B |

| HC B | Hoseclamp width side B |

| ID B | Inside Diameter side B |

| T OD B | Tube Outside Diameter side B |