Pressure Resistance for Flexible Connectors

0,34 Bar / 5.0 PSI For temperatures up to 90 °C / 195°F. Please see “Operating Pressure Guide” for further information. We recommend using the shortest possible connector for applications where increased pressure and/or high temperature is expected. Please contact us for more information.

ATEX & Explosion Safety

Explosion Pressure: no tests have been performed, this can be done upon request.

Electrostatic Surface Resistance:

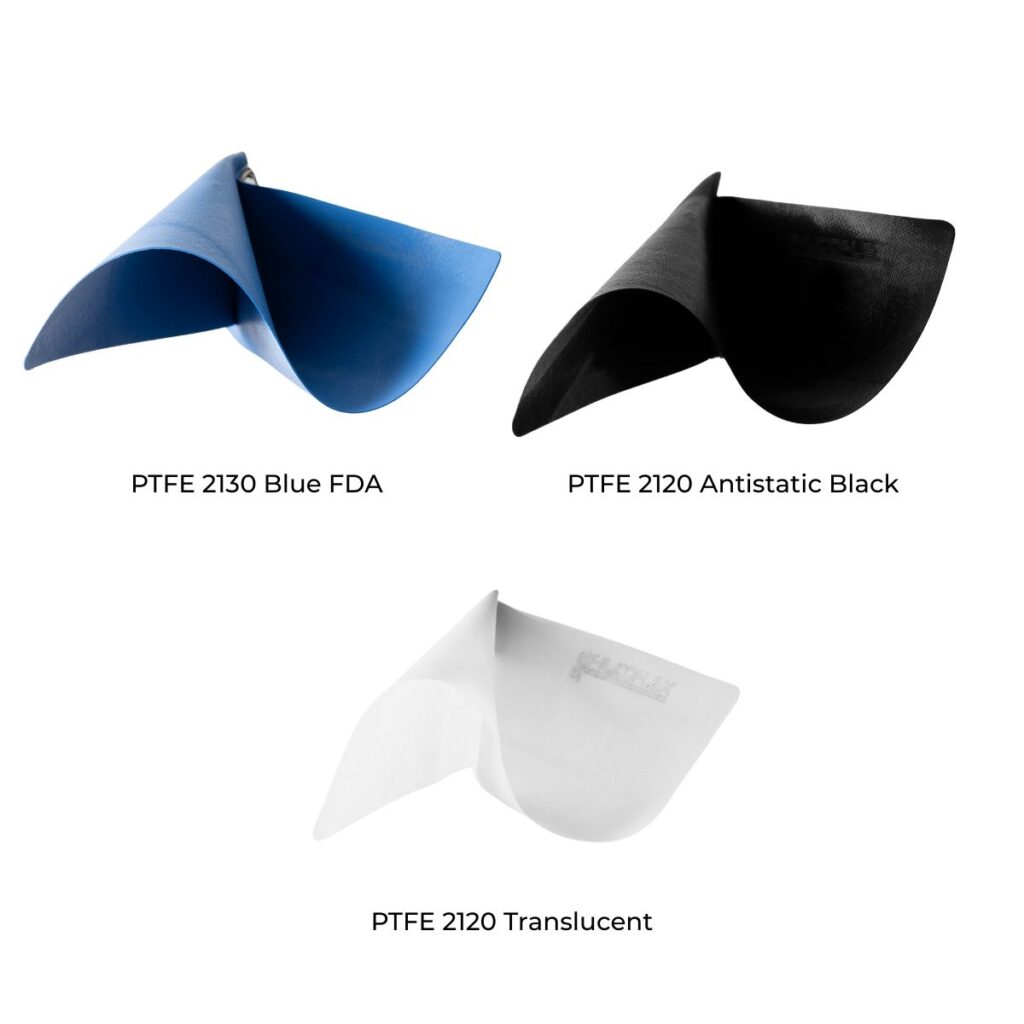

- PTFE2112 AS Black FDA: < 106 Ohm – Conductive

- PTFE2120 AS Black FDA: < 106 Ohm – Conductive

- PTFE2120 Translucent FDA: > 1,8 x 109 Ohm – Insulating

- Sleeve Length: < 100mm

Airspeed not important

= Powders MIE* > 1mJ - Sleeve Length: 100 – 1000mm

Airspeed > 2m/s

= Powders MIE* >1000mJ

Airspeed < 2m/s = Powders MIE* >10mJ

- Sleeve Length: < 100mm

*MIE means Minimum Ignition Energy

Despite being insulating the material has been tested, to which relation it can be used in powder and dust transportation system. The relation between airspeed, maximum sleeve length and Minimum Ignition Energy of the powder or dust has been well documented in a report so that PTFE2120 can be implemented in explosion hazardous environments if designed within described parameters.

Name of the reports:

‘9075, Report Suitability flexibles 2015 Filcoflex 02.pdf’

‘TL9075TestReport_Filcoflex_original.pdf’

Both reports are available upon request.

Chemical Resistance

- CIP resistant (see CIP chemicals guide)

- Cleaning Chemicals (see cleaning guide)

- For a detailed chemical resistance please see our chemical compatibility chart

PTFE films of other thicknesses or colors have not been tested thus far.

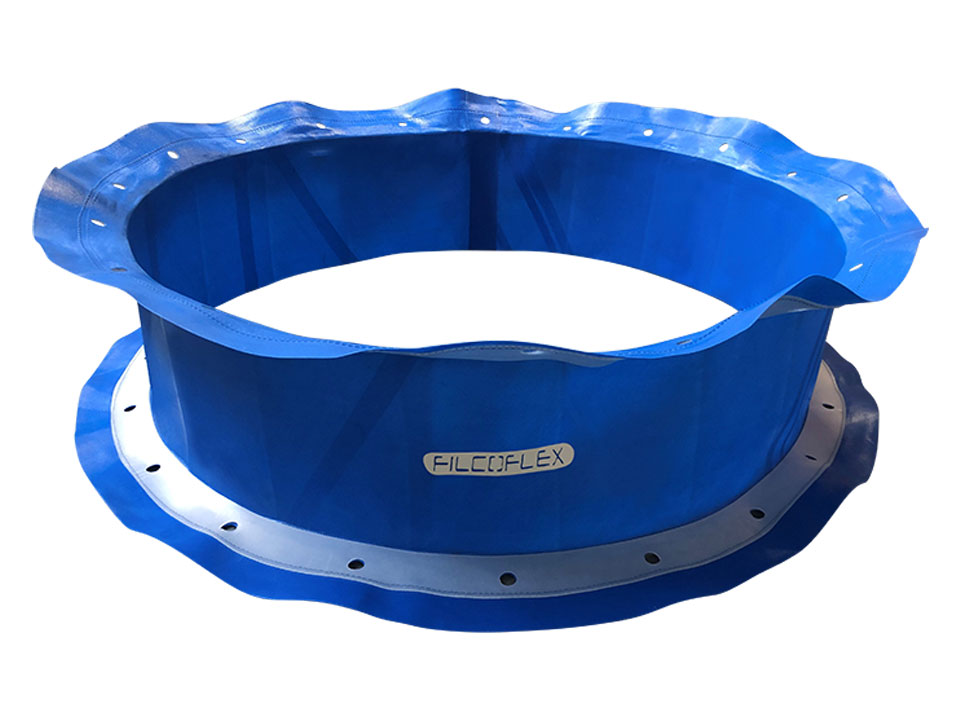

Availability for shapes, couplings and product features

PTFE film can be custom made in to many flexible sleeve and many other products. This document summarizes all the different shapes, end couplings and product features that are available for this flexible material.

Please find detailed explanations on the information pages about these subjects:

- product features & options

- shapes & forms

- coupling ends