- Products

- Technical

- Customize

- Material

- About

- Contact

The dairy Industry often asks Euro Manchetten & Compensatoren about food safety and avoiding the danger of explosions. When we found out our partner-companies VDL Industrial Products and Filcoflex receive similar questions just as frequently, we decided to organise a seminar.

The awareness event ‘Explosions Safety in Dairy Industry’ took place on the 24th of January in Zwolle. The interesting guest speakers in the fields of hygiene and static release attracted many process experts from the dairy industry.

In the fi rst presentation Gerard van Laar from Inburex consulting kicked off the day by explaining the concept of static charge and the static hazards than can occur in the production process. He illustrated this with a reallife case study and this way he set the right tone for the other speakers to follow up.

What is required by the European legislation and regulations (VDI 2263-7) when it comes to the use of spray dryers? Dr. Bernd Broeckmann from Inburex consulting followed this subject with an explanation of how products are tested for their explosion characteristics.

What is a safe way to uncover how an explosion behaves? By letting them go off in large test barrels. Dr. Franz Alfert from Atext Explosionsschutz reported on the experimental research that has been done on this topic.

With an advanced method, you can pinpoint where dew points can be found. Sadiq Bokhari and Marcus Kendik of Acom shared all the ins & outs about these new opportunities. They also discussed the latest news around CO-detection systems.

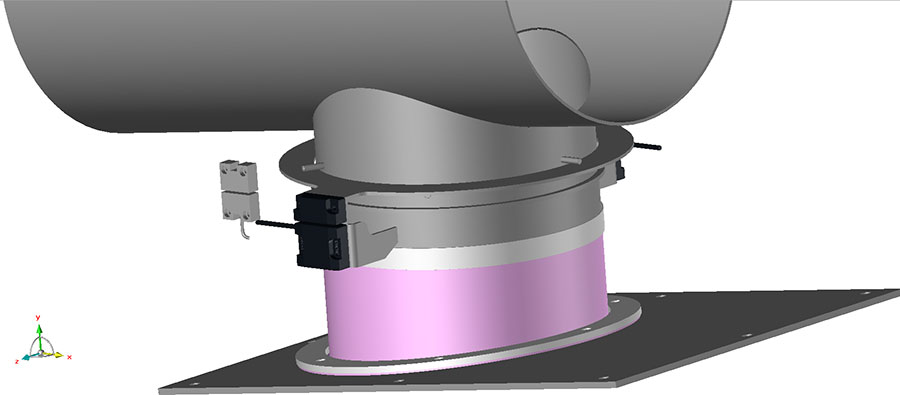

Besides the guest presentations, demonstrations of systems and installations that avoid dust explosions or minimise them also took place. And of course, the attendees had the opportunity to share experiences and to network with each other.

Andrea Van Loon of Euro Manchetten & Compensatores, co-organiser of the event, looks back enthusiastically: ‘It was a great day, brimming with the exchange of knowledge. The guest speakers came with interesting examples straight out of their professional experience and catered to an engaged audience that asked interesting questions. The demonstrations also grabbed a lot of attention. This was exactly the point of the event, because by sharing expertise, we are much stronger in the pursuit of optimum process safety.’