Features

- Easy universal coupling

- Any size available

- Fully custom made diameters

- Metric and Imperial

- Roll of 3000mm max

- High tear resistance

- Fantastic for commission tests

- Great for temporary sleeves

- Explosion Resistant 1,5 Bar

- Poly Urethane 0.3mm / 1.0mm / 1.5mm

- EG 1935/2004, 10/2011, FDA, BG, ATEX

Hose on roll

A quick and easy way to connect pipes or moving machine parts can be with a sleeve that is fitted with hose clamps on each side. These types of connectors are usually easy to make and easy to assemble. The hose clamps can be adjusted to any tightness. Polyurethane Hose on Roll can be used on round or oval ducting and tubing.

Polyurthane Hose on Roll is custom made to diameter. Since polyurethane is a thermoplastic material, no glue is used or any additive. The polyurethane is simply welded in to a tube shape in any diameter required for the right fit.

The lengths of sleeves often variate. With Hose On Roll you can cut the required length of your stock roll. This makes it the perfect universal stock item that can be used on many different positions in a factory or during commission testing of a new system or machine. If the right length flexible connectors still need to be ordered with Jacob or tri-clamp flanges, using Polyurethane hose on roll is a good way to make temporary sleeve to commence the testing without the final sleeves being present yet. Sleeve over length and sleeve compression can be tested to have the right sleeve made for final delivery of the installation.

Hose On Roll is also ideal to make temporary or emergency repair sleeves with. You can make emergency repairs or temporary sleeves until you receive the new flexible connections with flanges, Jacob or tri-clamp coupling. It can function as a temporary sleeve to replace our FDM, FSC, LFR, or Snapring fitted Flexible connections. The diameter stretches with some force to the most used diameters. HOR Polyurethane is easy to store and takes up little space in stockrooms, in mechanics vans or containers of the on-site crew. All comply to FDA, EC1935/2004, and or 10/2011. All Poly Urethane 0.3mm, 1.0mm and 1.5mm are safe to use in ATEX zones 20, 21 and 22. Please check our testing reports for the right conditions of length, airspeed, minimum ignition energy, etc.

Materials

For more information please go to our Materials Comparison Table.

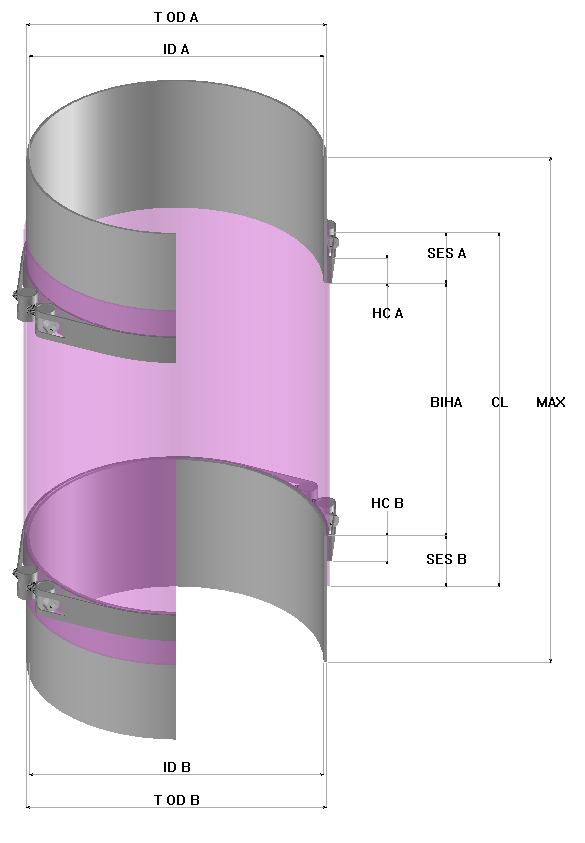

| Parameter | Explanation |

| T OD A | Tube Outside Diameter |

| ID A | Inside Diameter |

| HC A | HoseClamp width |

| SES A | Straight End Sleeve Length |

| CL | Length Sleeve Total |

| BIHA | Length Between Tubes / Flanges |

| MAX | Maximum Available Build in Height |

| SES B | Straight End Sleeve Length |

| HC B | HoseClamp width |

| ID B | Inside Diameter |

| T OD B | Tube Outside Diameter |